Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Benefits

- Outstanding Hide, Performance & Durability

- Long Lasting Interior Surface Protection

- Excellent Touch Up

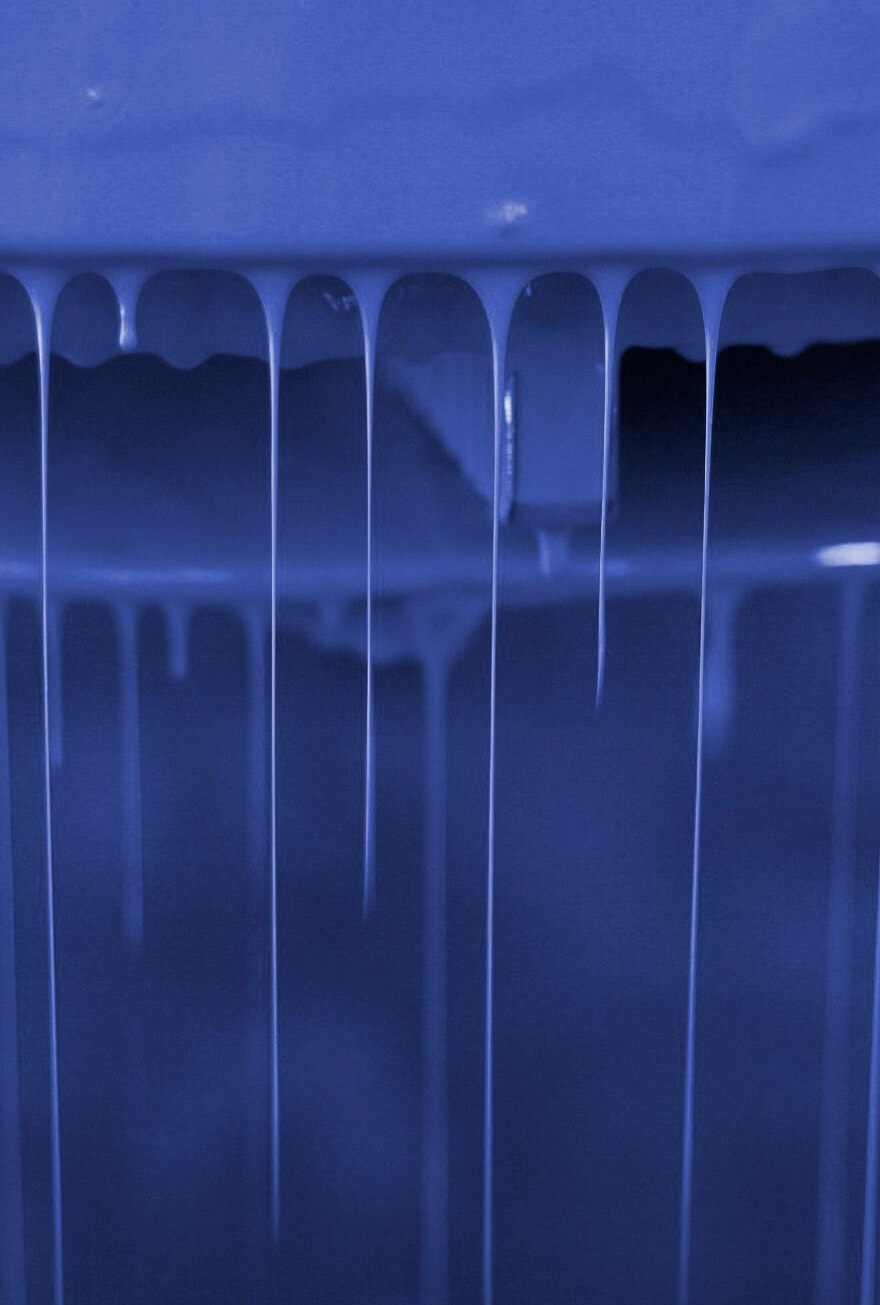

- Flows and Levels Out Smoothly

- Advanced Scrub Resistant

- Mildew Resistant Formulation

- Uniform Appearance as a Topcoat whether Spray, Brush, or Roll Application

- Spatter & Drip Resistant Finish

- Increased Light Reflection in Poorly Lit Areas

- Environmentally Friendly

- Non Flammable

- Non Yellowing

- Low Odor

- Easy To Apply

- Soap & Water Clean Up

Applications & Uses

- Markets

- Recommended Uses

New or previously painted Interior walls, ceilings, woodwork and trim surfaces as well as interior masonry, block, plaster, drywall, sheetrock, steel, and composition wallboard.

- Surface Preparation

- Surface must be clean, dry and free of dust, sanding dust, dirt, grease, oil, mold, mildew, lose wood fibers, flaking paint, chalk, soap residue, wax, corrosion, laitance, and all other contaminants or foreign matter that might impede adhesion. Existing peeled or checked paint should be scraped and sanded to a sound surface.

- Fill drywall cracks and holes with spackle or joint compound and sand smooth. Remove all sanding dust. Joint compounds must be cured. Bare plaster surfaces must be cured and hard. Textured, soft, porous, or powdery plaster surfaces should be treated with a solution of 1 pint of household vinegar to 1 gallon of water.

- Repeat until the plaster surface is hard. Rinse with clear water and allow plaster surface to dry. Wood surfaces must be structurally sound and completely dry. Patch all holes and imperfections with a wood filler or putty and sand smooth. New concrete, masonry, concrete block remove all loose mortar and foreign material.

- Concrete must be free of laitance, concrete dust, dirt, form release agents, moisture curing membranes, loose cement and hardeners. Concrete and mortar must be cured to the supplier’s recommendation – usually 30 days at 75°F. Remove mildew before painting by washing with a solution of 1 part liquid bleach and 3 parts water.

- Apply the solution and scrub the mildewed area, allow it to sit on the surface for 10 minutes then rinse thoroughly. Wear protective eyewear, clothing, and gloves. Gaps between, ceilings, walls, crown molding, and other interior wood trim can be filled with appropriate caulk after priming the surface.

- Glossy surfaces should be sanded dull to promote adhesion. Stains from water, smoke, ink, pencil, grease, etc. Should be sealed with the appropriate primer/sealer. Recognize that any surface preparation short of total removal of the old coating may compromise the service length of the system.

- Warning! Removing existing coating from surface by sanding, scraping or other mechanical means may create dust or particles containing lead, a hazardous substance. Avoid creating and breathing dust and other debris. Thoroughly clean all surfaces before and after painting.

- Breathing or eating lead-containing dust or debris can cause health problems, especially in children and pregnant women. Controlling exposure to lead or other hazardous substances requires the use of proper protective equipment, such as a properly fitted (niosh approved) respirator and proper containment and cleanup.

- Application

- Coverage - Will cover approximately 400 square feet per gallon on smooth sealed surfaces. Coverage figure does not include spray loss, loss due to surface porosity, surface irregularities, nor material loss when mixing.

- Mixing - Material does not require thinning. For color uniformity, inter-mix all cans together before use.

- Application Stir each container thoroughly before using and occasionally while applying to keep uniform consistency and color. Apply evenly with a nylon/polyester, brush, 1⁄2” – 1” synthetic roller cover, or spray. When applying by roller, roll from the dry area into the wet area using firm crisscrossing strokes. Finish with long even strokes in one direction. For airless application, use a 0.15 to 0.17” tip at 2000 psi. If spraying, always back brush or back roll immediately to ensure proper penetration and uniformity. Paint from a dry area in the adjoining wet coating area. Maintain a wet edge to avoid lap marks.

- Cleanup - Clean spills and spatters promptly. Clean hands, tools, and spray equipment immediately after use with soap and warm water. Give spray equipment a final flush with mineral spirits to help prevent corrosion. Follow manufacturer’s safety recommendations when using mineral spirits. Dispose of used paint and waste in accordance with local, state, and federal regulations.

- New & Unpainted Surfaces

- Concrete Block Surfaces - 1 Coat 7800 Block Filler & 2 Coats Imperial 2SP00

- Drywall Surfaces - 1 Coat 5099 PVA Primer & 2 Coats Imperial 2SP00

- Plaster Surfaces - 1 Coat 5099 PVA Primer & 2 Coats Imperial 2SP00

- Masonry Surfaces - 1 Coat 5099 PVA Primer or 1900 Primer & 2 Coats Imperial 2SP00

- Wood Surfaces - 1 Coat 5099 PVA Primer or 1900 Primer & 2 Coats Imperial 2SP00

- Allow 4 hours dry time before recoating with IMPERIAL 2LP00 LO-luster Coating.. On repaint work or previously painted surfaces, apply one coat of with IMPERIAL 2SP00 Semigloss Coating. On repaint work or previously painted surfaces, apply one coat of IMPERIAL 2SP00 Semigloss Coating.

Properties

- Color

Safety & Health

- Precautions/Limitations

- For interior use only

- Not for use on wood, metal or other surfaces that are constantly damp or wet.

- Do not apply when material, air, and/or surface temperature is below 50°F (10°C).

- Not for use on floors or steps.

- Store at room temperature.

- Non-Photochemically Reactive

- Mildew Resistant

This coating contains agents that inhibit the growth of mildew on the surface of this coating.

- Environmental & Safety Statement

This product is not formulated with any lead, chrome or mercury containing ingredients. The maximum VOC does not exceed 250g/L. Do not take internally. Keep out of the reach of children. Use with adequate ventilation.