Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

Applications & Uses

- Applications

- Application Method

- Surface Preparation

General: surfaces to be finished must be clean, dry and free of dirt, oil or any contamination that would adversely affect adhesion, protective properties or appearance of the coating.

- Mixing & Thinning

Stir each container thoroughly prior to use. Material is packaged at a viscosity requiring little of no reduction for application by spray equipment. Solvents of choice are toluol, xylol, SC-100 and SC-150. For cool weather conditions (below 65°F) use xylol. For temperatures above 80o F, xylol may still be used, but SC- 100 or SC-150 can be used as a retarder solvent to reduce dry spray and increase flow and leveling. Limit the level of SC-150 to 5% as a retarder solvent. VM&P naptha may also be used, but higher levels to achieve the same viscosity reduction will be required vs. aromatic solvents. To store partially used container, pour a small amount of the recommended thinner over the surface. Do not stir. Replace lid securely. Store away from heat or open flame. Mix thoroughly before reusing. 92R16 Primer may also be catalyzed with Polyurethane Converter to create a hard, solvent and chemical resistant finish that is free from “after tack”. Mix 8 parts primer to one part Polyurethane Converter (8000) by volume. Use within a four-hour time period. Due to short pot life, never leave catalyzed paint in spray equipment. Clean immediately! Do not spray catalyzed material with heated spray equipment.

- Uses

Use xylol, aromatic solvent or MEK for cleaning guns and equipment.

- Applications

- In most cases, an application over a primed or phosphated surface will provide adequate durability. Application rate will vary widely depending on texture, configuration and porosity of surfaces on which coating is applied. Approximately 350-400 square feet per gallon on smooth surfaces (32-37 square meter per 3.785 liters). Rough or porous surfaces will require more paint. Approximate dry mil thickness of 1.3 mils at recommended application rate of 400 square feet per gallon on smooth surface. A dry film thickness of 1.0-1.5 mils is recommended.

- Material can be applied by conventional air, air-assist airless, airless, dip or more advanced application equipment such as turbo disk or bell. This product may also be applied with electrostatic and/or heated equipment. Not recommended for brush or roller application over large areas. Small touchup areas may be brushed.

- Drying

Optimum drying conditions are 60°F to 90°F (16°C to 32°C) at 50% R.H. Lower temperatures and high humidity will slow dry. Surface must be dry and at least 5°F above the dew point. Dry to Touch 15-30 minutes. Product may also be force cured to enhance dry. Temperatures in the range of 110-180°F may be utilized to accelerate solvent evaporation and speed oxidation.

Properties

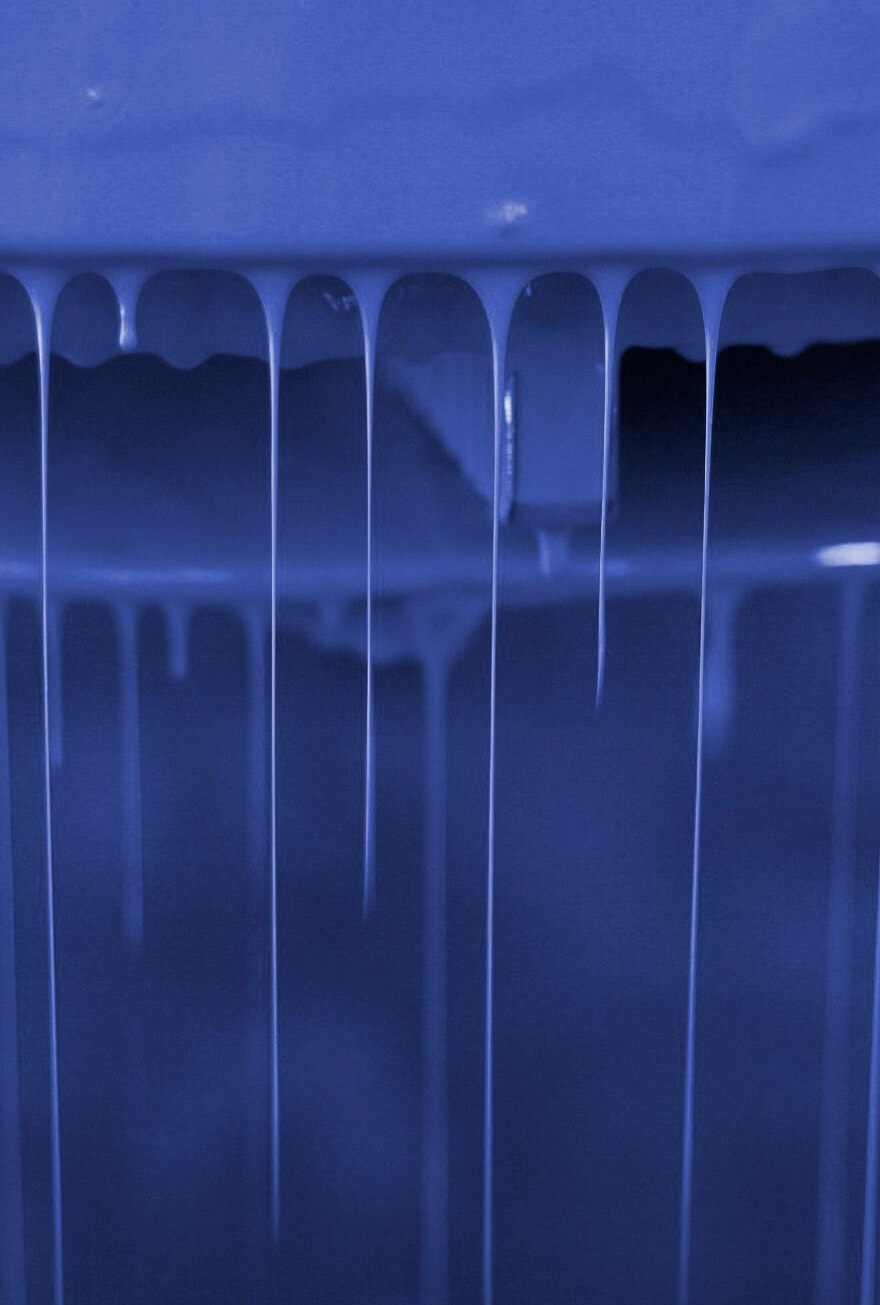

- Color