Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

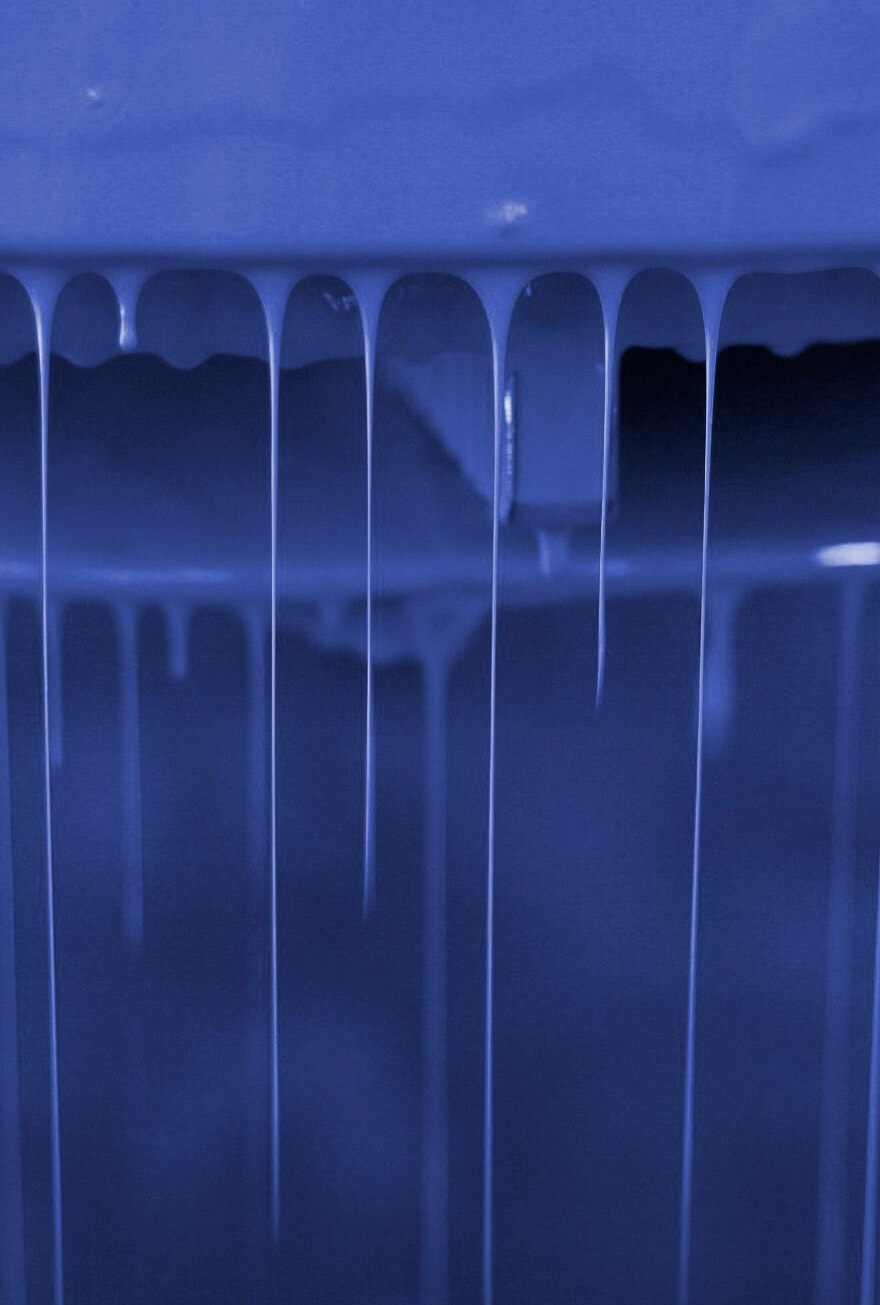

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Benefits

- Can Be Cross Linked with 8000 Polyurethane Converter

- Excellent Resistance to U.V. Exposure

- Excellent Durability

- Good Abrasion Resistance

- Resists Chipping

- Excellent Color Retention

- Excellent Chalk Resistance

- Brushed, Roll, or Spray

- Excellent Brushing Characteristics

- High Hiding

Applications & Uses

- Applications

- Application Area

- Compatible Substrates & Surfaces

- Uses

Substrates include both interior and exterior applications on ferrous metals, wood, and masonry as well as O.E.M. farm machinery, feed & grain bins, livestock equipment, structural steel, tanks, trailers, and general industrial finishing where a high performance paint coating is desired.

- Surface Preparation

Surface must be clean and dry. All substrates must be cleaned free of dust, dirt, oil (including form oils & parting compounds), grease, soap residue, wax and flaking paint. Scuff sand slick, hard, glossy surfaces to promote adhesion. Sandblast or wire-brush rusty surfaces and prime with 82 Series Primers. Refer to Surface Preparation Guide for more detailed instructions.

- Applications

- Mixing: Hand stir each container thoroughly before using and occasionally while applying. No thinning usually required. If necessary, thin sparingly with mineral spirits.

- Application: Apply using a high quality brush, roller or by spray. For airless application, use a 0.011-0.015”(0.28-0.38mm) tip. For air spray use 50 psi (3.52 Kg/cm2 ) air pressure and 8 psi (0.56 Kg/cm2 ) fluid pressure with conventional air cap, tip and needle. When using #8000 Polyurethane Converter, the material will have a pot life of 24 hours.

- Coverage: One gallon will cover approximately 400 square feet per coat on smooth surfaces. Coverage figure does not include spray loss, loss due to surface porosity, surface irregularities, nor material loss when mixing.

- Cleanup: Clean spills, spatters, hands, tools and other equipment promptly with mineral spirits. Dispose of used paint and waste in accordance with local, state, and federal regulations. Follow manufacturer’s safety recommendations when using mineral spirits.

- Application Precautions & Limitations: Apply when surface, air, and product are above 40°F (4°C) and at least 5°F (3°C) above the dew point.

Properties

- Color