Knowde Enhanced TDS

Identification & Functionality

- INCI Name

- CAS No.

- 102687-65-0

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Features

It’s time to discover new ways that we can all help preserve our planet without comprising on product performance. Solstice Enhance (HFO-1233zd(E)), a breakthrough solvent and carrier fluid, is ideal for face, body, hair, and sun care products. It offers exciting possibilities to develop unique products that your customers are seeking.Based on our next-generation hydrofluoroolefin (HFO) technology, Solstice Enhance can help reduce climate impact. With an Earth-friendly1 ultra-low global warming potential (GWP) of one, it can be used as a multifunctional ingredient that can replace hydrofluorocarbons (HFCs), hydrocarbons, alcohols, menthols, cyclic silicones, and other ingredients. Not only does Solstice Enhance help keep your products ahead of changing environmental regulations, it provides exceptional formulating benefits such as: - Nonflammable (ASTM E-681, EU A11) – an effective alternative to flammable ingredients, or to help reduce formulation flammability2 - Enables non-irritating instant cooling, fast drying, unique foaming action and new textures - Can be used in combination with Solstice® Propellant and other ingredients to create novel recipes - Can replace cyclic silicones, such as cyclopentasiloxanes (D5), which are under regulatory scrutiny in Europe. It can be used in formulations when blended with natural oils and other cosmetic oils. - Soluble with a wide range of personal care ingredients - Excellent surface wetting and spreadability Additional environmental benefits include: - Ultra-low GWP = 1 – reduces carbon dioxide equivalent emissions by 99.9% compared to hydrofluorocarbons (HFCs) - Non-ozone-depleting - VOC-exempt (per U.S. EPA) – pending CARB VOC-exemption approval - Negligible contribution to smog formation This brochure provides technical information about Solstice Enhance including its physical properties, environmental attributes, exposure guidelines, and other important features. The information provided is but some of a mosaic of properties that must be evaluated in assessing candidate ingredients.

Applications & Uses

- Hair Care Applications

- Skin Care Applications

- Sun Care Applications

- Treatment Product Applications

Properties

- Physical Form

- Appearance

- Colorless

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Molecular Weight | 130.5 | g/mol | — |

| Boiling Point | 19 (66) | °C (°F) | — |

| Liquid Density (25°C) | 1.26 | g/ml | — |

| Latent Heat of Vaporization at Boiling | 192 (82.5) | kJ/kg (BTU/lb) | — |

| Freezing Point | -107 (-161) | °C (°F) | — |

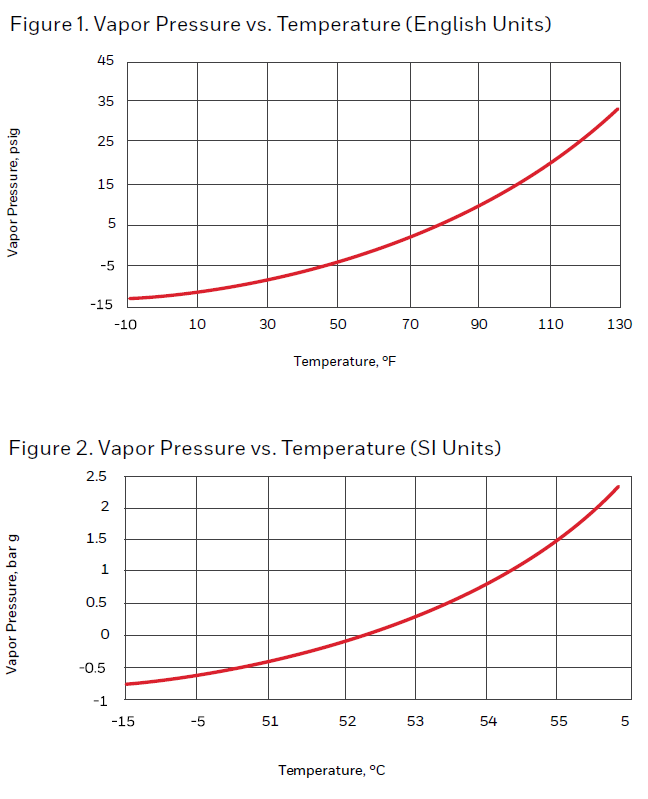

| Vapor Pressure at 25°C (77°F) | 0.30 (4.11) | bar g (psig) | — |

| Surface Tension at 25°C (77°F) | 12.7 | dyne/cm | — |

| Solubility of Water in Solvent at 25°C (77°F) | 460 | ppm | — |

| Hansen Solubility Parameters - Dispersion | 15.5 | — | — |

| Hansen Solubility Parameters - Hydrogen Bonding | 2.2 | — | — |

| Hansen Solubility Parameters - Polarity | 4.8 | — | — |

| Kb (Kauri-butanol) Value | 25 | — | — |

| Stable pH Range3 (evaluated range) | 3.5 - 11.7 | — | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Formulating Flexibility

Solstice Enhance is completely miscible with halogenated solvents, hydrocarbon solvents, alcohols, ketones, and commonlyused propellants. Because Solstice Enhance offers excellent solubility across a wide range of personal care ingredients, it provides unique formulation flexibility and latitude (Table 4). Cooling gels, dry shampoos, cooling misting sprays, and self-foaming cleansers are just some of the innovative formulations being developed.

Table 4. Ingredient Solubility in Solstice Enhance4

PROTIC SOLVENTS 50% 25% 10% Ethanol Y Y Y Glycerin N N N 1,3 Butylene Glycol N N N Propanediol (Zemea) N N N Phenoxyethanol Y Y Y ETHERS/POLYETHERS Dimethyl Isosorbide Y Y Y Ethoxydiglycol Y Y Y Polysorbate 20 Y Y Y Laureth 4 Y Y Y SUNSCREENS Octinoxate Y Y Y Octasalate Y Y Y Octocrylene Y Y Y Homomenthyl Salicylate Y Y Y TRIGLYCERIDES Caprylic/Capric

TriglycerideY Y Y Olive Oil Y Y Y Safflower Oil Y Y Y Soybean Oil Y Y Y ESTERS 50% 25% 10% C12-14 Alkyl Benzoate Y Y Y Neopentyl Glycol

DiheptanoateY Y Y Trioctyldodecyl Citrate Y Y Y Glycereth-7 Citrate N N Y Triisocetyl Citrate Y Y Y Octylhydroxystearate Y Y Y Diisopropyl Adipate Y Y Y Ethylhexyl Palmitate Y Y Y HYDROCARBONS Isododecane Y Y Y Hydrogenated Polyisobutene Y Y Y Squalane Y Y Y SILICONES Dimethicone (350 cks) Y Y Y Dimethicone (0.65 cks) Y Y Y Cyclopentasiloxane (DC 345) Y Y Y Phenyl Trimethicone Y Y Y LIQUID FATTY ALCOCOLS Octyl Dodecanol Y Y Y OTHER Perfluorodecalin Y Y Y - Materials Compatibility

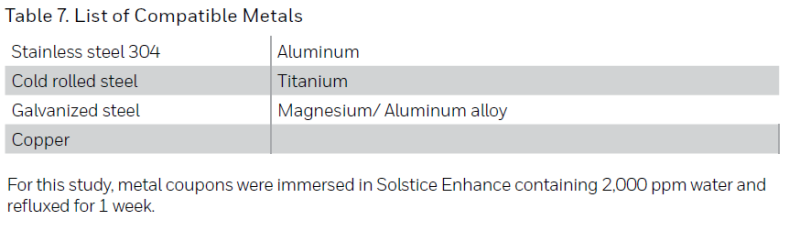

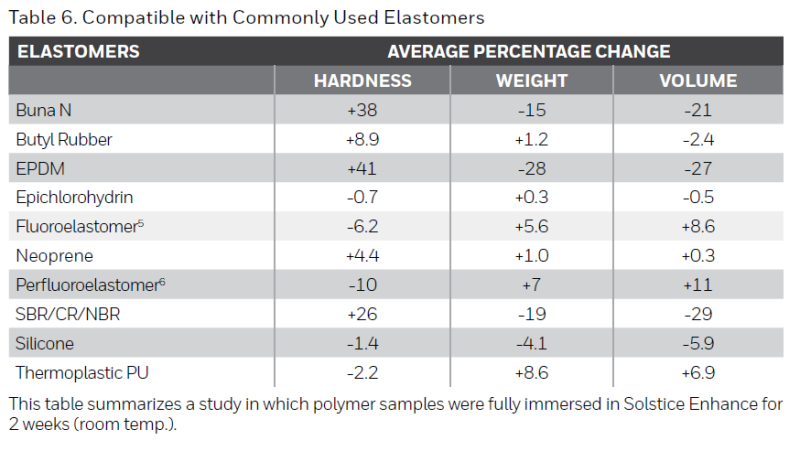

Solstice Enhance is compatible with many commonly-used plastics (Table 5) and elastomers (Table 6). It is important to recognize that results may vary with different grades and manufacturers of the same polymer. Therefore, when evaluating a material for compatibility with Solstice Enhance, it is recommended that the manufacturer be consulted, or further independent testing be completed. Results shown should be used only as a guide. Solstice Enhance is compatible with many commonly used metals. Halide analysis indicated no chemical breakdown, no degradation, rusting, or pitting observed for the metals tested (Table 7).

Table 5. Compatible with Commonly Used Plastics

PLASTICS AVERAGE PERCENTAGE CHANGE WEIGHT VOLUME 2 weeks

Rm. Temp.4 weeks 50ºC

(122°F)2 weeks Rm.

Temp.4 weeks 50ºC

(122°F)ABS 3.6 38.7 3.6 27.8 HDPE 1.7 3.5 1.2 2.5 HIPS 23.3 25.4 83.1 45.3 Nylon 66 -0.1 -0.3 -0.1 -1.8 PEEK -0.0 N/A -0.3 N/A PET 0.1 0.2 0.0 0.5 PET (bottle) N/A 1.6 N/A 1.5 Polycarbonate 3.5 13.7 3.0 8.7 Polyetherimide 0.0 0.5 -0.5 -0.5 Polypropylene 5.0 6.1 3.7 5.2 PTFE 2.1 2.7 3.9 3.5 PVC-type 1 0.1 1.7 0.0 0.1 PVDF 0.1 0.9 -0.3 0.9 This table summarizes a study in which polymer samples were fully immersed in Solstice Enhance for 2 weeks (room temp.) and 4 weeks (50°C / 122°F).

- High Thermal and Hydrolytic Stability

Laboratory tests indicate that Solstice Enhance has a high degree of thermal and hydrolytic stability. In sealed tube studies, the neat material was judged to be thermally stable after 2 weeks of exposure at 150°C (302°F). Additional sealed tube studies were conducted to evaluate both the thermal and hydrolytic stability of Solstice Enhance with metals and water. After 2 weeks of exposure at 150°C (302°F) in the presence of metals (3003 aluminum, copper, and / or 316 stainless steel), in the presence of water (at 300 ppm), and in the presence of metals and water, no chemical breakdown of Solstice Enhance was detected.

Cans: Solstice Enhance is compatible with typical aerosol packaging materials, such as tinplate cans and lined cans (Table 8).

Valves: Several aerosol valve manufacturers evaluated the compatibility of Solstice Enhance with valve seals. Aptar Pharma7 and Precision Global8 both reported good results with grades of buna and butyl rubber. Summit Packaging Systems developed bagon- valve (BOV) compatibility data showing Solstice Enhance is compatible with 3-ply polyethylene (PE), 4-ply PE, and 4-ply polypropylene laminated BOV pouches.9 For assistance with valve selection, consultation with a supplier is recommended.

Table 8. Compatible with Common Aerosol Packaging Materials

LINER MATERIAL SUPPLIER STORAGE TIME

@ 40°C / 104°FRESULTS PET DS Container 19 months Compatible Epoxy Exal 1 year Compatible PAM Exal 1 year Compatible Lined aerosol cans containing Solstice Enhance were monitored during aging at 40°C (104°F) for changes in liner appearance, acidity, and non-volatile residue. Results demonstrated good compatibility.

Safety & Health

- Environmental Health and Safety

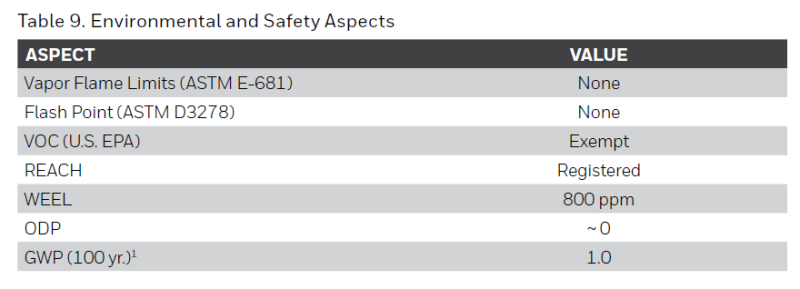

Solstice Enhance is nonflammable (ASTM E-681, EU A11), non-ozone-depleting

(ODP ~ 0), and has an ultra-low global warming potential (GWP=1). Unlike hydrocarbons, Solstice Enhance is not a volatile organic compound (VOC). Due to its low Maximum Incremental Reactivity (MIR), it does not contribute to smog or create ground level ozone. Solstice Enhance exhibits no flash point at 21°C (70°F). Also, no vapor flame limits were observed up to 100°C (212°F), the highest temperature tested by Honeywell.For more Details on Enivironmental Health and Safety

Storage & Handling

- Safe Use And Handling

Before handling or using Solstice Enhance, Honeywell recommends carefully reviewing the information in the Safety Data Sheet (SDS). The SDS may be viewed online at the Honeywell SDS Resource Center: www.honeywellmsds.com. Copies of the SDS may also be obtained by contacting Honeywell at 1-800-631-8138 within the U.S. and Canada, or by contacting the local Honeywell sales office. Solstice Enhance is supplied incylinders that meet U.S. Departmentof Transportation (DOT) requirementsand comply with all applicable codes and regulations for the regions in which they are transported. The material should be stored at room temperature (>24°C / 75°F) to allow for easy liquid dispensing, and in a well-ventilated area. Solstice Enhance can be handled as a liquid during formulation work and laboratory studies. Although its boiling point is just below room temperature (19°C / 66°F), it has a high heat of vaporization so it does not instantly vaporize at room temperature. This allows ample time to formulate and work with the product. The 10-lb. sample cylinder outlet has a CGA 165 fitting which accepts a standard 1/4” S.A.E. 45° flare connector. This is a common refrigeration fitting. Connect the fitting/tubing assembly to the red liquid valve outlet. Liquid should flow freely when the valve is opened. You can collect the liquid in a pressure-resistant, sealable glass container for convenient handling. If you find there is not enough pressure in the cylinder to dispense the liquid, you can invert the cylinder and dispense liquid through the blue vapor valve. When not in use, store Solstice Enhance in a clearly labeled, pressure-resistant, sealable container in a refrigerator (not used for food). This helps to lower pressure inside the container.