Knowde Enhanced TDS

Identification & Functionality

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Character

- Causing the permanent anti-static property to styrene resins

- Injected parts will still show original anti-static abilities after many times watern washing as per suitable process to compound styrene resins with HSINSOU NYPAS in proper ratio ,HSINSOU NYPAS gives the styrene resins a permanent antistatic property.

- Slightly influences to mechanical property of styrene resins.

- Superior heat stable ability ,thus less influences to styrene resins in heat applications.

- Suitable for I C relative products and other easily hurting of sensitive in static environment

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Application Method

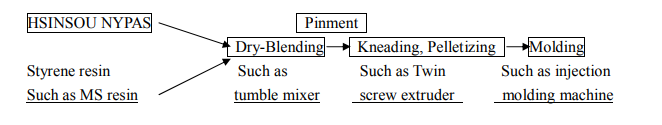

1). General procedure

As shown in figure 1 .HSINSOU NYPAS and styrene resin are recommend process as following : . Pigment may be added as necessary during the dry-blending process or the neading process dry-blended using a blender , such as tumble , and are neaded and pelletized using a twin screw extruder.

Figure 1. General procedure for application of PLEASTAT NC 7530

2.Amount to be Applied

ABS : As per previous process , 20 % NYPAS to be added

HIPS : As per previous process , 15 % NYPAS to be added3. Kneading Conditions

- Use a high share rate kneader ,such as a twin screw extruder.

- Standard kneading temperature is between 160 ℃ ~ 170 ℃ , Determine the kneading temperature according to the resin applied.

- The Highest process Temperature for each different facility are around 200 ℃~210℃ .As lower as possible while process NYPAS into extruder, recommend process in between 150 ℃ to 170 ℃.

- Other resin undetermined need to have more confirmation.

- Drying of HSINSOU NYPAS

4. Drying

HSINSOU NYPAS has some hygroscopic character , but is packed in bags under moisture proof conditions ; no drying is necessary when used just after unsealing . If HSINSOU NYPAS is kept open for a long time (about 72 hours) , after unsealing , drying is necessary

Properties

- Appearance

- Pale yellow Pellet

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Melt Flow Rate (190 ℃ , 21.18 N) | 0.98 | g/10min | ASTM D 1238 |

| Surface Resistivity (25°C, RH 55%) | 10^6 - 10^7 | Ohms | ASTM D257 |

| Thermal degradation Temperature (Nitrogen) | 289 | ℃ | Start to degradation |

Technical Details & Test Data

- Performance Tests

With refer to the extended test of ABS and HIPS , it show the absolutely superior permanent anti-static property ,to other low molecule weight of anti-static materials .