Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Industrial Additives Functions

- CAS No.

- 7440-02-0

- EC No.

- 231-111-4

- Technologies

- Morphology

Filamentary

Applications & Uses

- Markets

- Applications

- Battery Type

- Industrial Additives End Use

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Apparent Density | 0.64 | g/cm³ | — |

| Particle Size | 2.6 | μm | Fisher Sub Sieve Sizer |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Particle Size Distribution

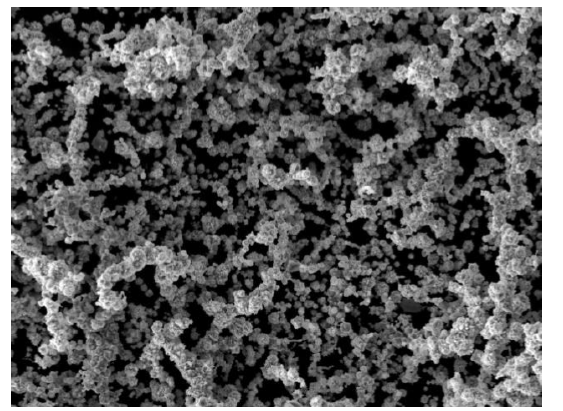

Grade AH45, shown here at 2500 x magnification, one of many Nickel Powders and Flakes available.

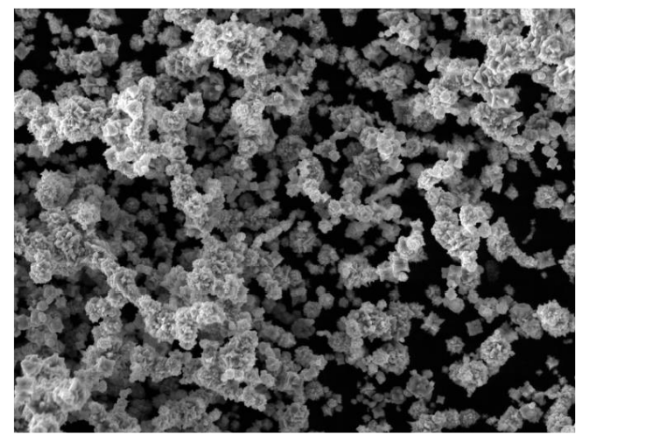

Grade AH45 – at 5000 x magnification, characterized by filamentary morphology

Packaging & Availability

- Packaging Type

- Packaging Information

- 25 kg (55.12 lb) pails

- Custom packaging available upon request

- Other Consumables

In addition to Nickel Powder Grade AH45, Hunter Chemical offers nickel powders in various grades for a wide variety of applications.

- Nickel Powder AH50 – A spherical shape with spiky surface used in P/M and other applications.

- Nickel Flake NF50 – An irregular-shaped platelet with high average aspect ratio for use in a variety of applications.

- Nickel Powder Grade AH440/AH410 – Spherical shape with mottled surface and greater density for MIM and other applications.

- Nickel Powder Grade OH series – The OH series of Nickel Powders is produced through a hydrometallurgical process, also known as Hydrogen-Reduced or the “Sherritt-Gordon” process. It is further processed into different particle size distributions for various applications.