Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- CAS No.

- 110553-27-0

- EC No.

- 639-900-9

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Compatible Polymers & Resins

- Applications

ANTIOX 1520 SE is recommended for emulsion and elastomer suspensions, such as BR, SBR, natural rubber, etc. It protects the substrates against thermo-oxidative degradation during the production process and during the long-term heat aging. If necessary, it can be used together with primary and/or secondary antioxidants, light stabilizers, etc.

Properties

- Appearance

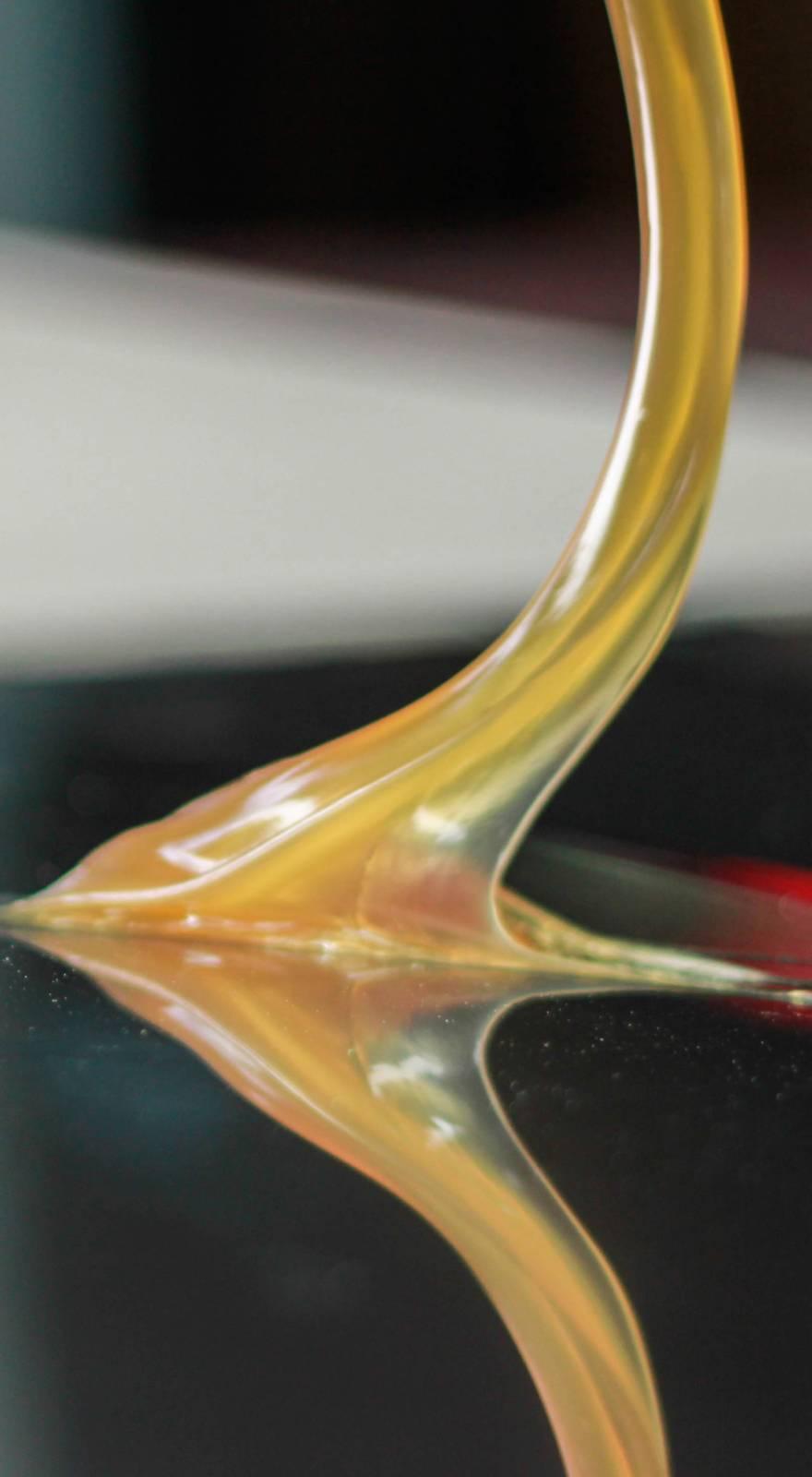

- Limpid yellow liquid

Packaging & Availability

- Packaging Type

- Packaging and Storing

Packaging

The product is supplied in plastic drums (50 kg); iron drums (200 kg).

Storing

Keep the product at room temperature, protected from direct sunlight and humidity. Use within 24 months from production date (unopened and in the original packaging).

Storage & Handling

- Shelf Life

- 24 Months

- Handling

Thanks to its low viscosity, ANTIOX 1520 SE can either be added directly into a polymer latex or added to water, forming a pre-emulsion. The quantity to be used depends upon the application, the substrate and the process.

Recommended quantity: 0.05-1%.