Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Advantages

Curing: PENESEAL™ FH allows concrete to cure uniformly through its chemical and moisture retention reaction. This aids in a more complete hydration process and reduces hairline and temperature cracking.

Sealing: PENESEAL™ FH penetrates deep into the concrete, which allows its chemical reaction to lock the pores from within, providing an integral and permanent seal.

Hardening: PENESEAL™ FH binds the elemental parts of the concrete, solidifying them into a denser, tougher, harder mass. This results in a more durable concrete with higher surface abrasion resistance and compressive strength.

Dustproofing: PENESEAL™ FH densifies the surface of the concrete through its chemical bonding and flushing of the weaker concrete salts and minerals. This permanently seals the surface and eliminates surface dusting.

Protection from efflorescence and leaching: PENESEAL™ FH penetrates deeply into concrete, neutralizing the alkali salts and minerals that cause efflorescence and salt leaching. These weakening salts and minerals are forced to the surface and flushed away during the application process.

Improved Bonding: PENESEAL™ FH eliminates the alkali salts and minerals that weaken and delaminate surface coatings. PENESEAL™ FH leaves the concrete surface free of these salts and minerals, which improves bonding of any type of covering.

Non-Toxic: PENESEAL™ FH is non-toxic and is not harmful to lungs or hands.

Applications & Uses

- Applications

- Application Method

- Compatible Substrates & Surfaces

- Applications

- Any cementitious based substrate such as, but not limited to:

- concrete

- Terrazzo

- Heavyweight concrete block

- plaster

- Stucco or mortar

- Warehouses

- Hangars

- Distribution and storage facilities

- Food processing plants

- Manufacturing facilities

- Any type of facility with exposed concrete flooring

- Surface Preparation

Surfaces to be treated should have an open pored surface so that PENESEAL™ FH can be absorbed. Remove all coatings, form oils, curing or sealing agents through chemical or mechanical means. Remove dust, dirt, laitance or any other contaminants by sweeping all areas to be treated with a fine bristle broom or scrub brush. Hose off with water and let dry. Remove any standing or puddled water to avoid dilution of PENESEAL™ FH before it is able to penetrate the surface.

- Mixing

Prior to use, agitate bucket or drum and thoroughly mix PENESEAL™ FH with clean water in equal parts by volume.

- Application Methods

For new concrete:

- Apply PENESEAL™ FH immediately following the concrete finishing, as soon as the concrete surface is firm enough to walk on and before hairline or temperature cracking begins. Keep the entire surface wet with PENESEAL™ FH for 30 minutes, working it into the surface with a soft-bristled broom

- As PENESEAL™ FH becomes slippery underfoot, lightly mist the surface with water. This will keep the material in solution providing maximum penetration. Do not allow PENESEAL™ FH to dry on the surface

- As PENESEAL™ FH again becomes slippery underfoot, thoroughly flush the entire surface with water and squeegee the surface completely dry to remove all surface alkali or PENESEAL™ FH residue. On exterior broom finished surfaces, no flushing is required, but any remaining PENESEAL™ FH must be squeegeed or broomed from the surface after 30-40 minutes. Do not allow PENESEAL™ FH to dry on the surface

For old concrete (All cured surfaces):

- Saturate the surface with PENESEAL™ FH so the entire surface is wet for 30 minutes. Mist with water if necessary to keep from drying on the surface

- (Option 1). If after 30-40 minutes the majority of PENESEAL™ FH has been absorbed into the surface, broom or squeegee any excess material from all low spots and puddles so all remaining PENESEAL™ FH is totally removed from the surface. Porous surfaces may require an additional application of PENESEAL™ FH to achieve maximum protection

- (Option 2). If after 30-40 minutes the majority of PENESEAL™ FH is still on the surface, wait until it becomes slippery underfoot, then thoroughly flush the entire surface with clean water and squeegee completely dry to remove all PENESEAL™ FH residue

- Application Notes

Application temperature limits: 40ºF to 100ºF (4°C to 38°C). The reaction of PENESEAL™ FH will be slowed at low temperatures. In these cases, the concrete should be protected from freezing for six days.

Drying time: 1-3 hours. The surface can be used as soon as the application is complete and the surface is dry to the touch.

Number of applications required: Typically only one application is required. An additional application may be required on porous substrates to achieve maximum performance.

Time requirement for curing, sealing and hardening: 60-90 days. PENESEAL™ FH seals concrete from within by permanently locking the pores, thus making the concrete itself the penetration barrier. This process is essentially complete within 90 days, but may continue at a much slower rate up to one year.

Color: Clear. PENESEAL™ FH will not change the natural appearance of the masonry or concrete. During application, all treated surfaces must be flushed clean with clean water to prevent impurities from drying on the surface.

Sheen: On smooth steel-troweled concrete surfaces, a natural wax-like sheen will appear between 6 and 12 months after treatment. This sheen is caused by the hardening and sealing effects of the PENESEAL™ FH, as well as the natural “buffing” action of foot traffic, cleaning and everyday use of the floor. The sheen is a permanent part of the concrete surface and will last the lifetime of the surface with proper maintenance.

Painting or covering preparation: On old concrete allow 3-7 days before applying paint or coverings to PENESEAL™ FH treated surfaces. On new concrete allow 30 days for proper curing of the concrete.

Duration of effectiveness: PENESEAL™ FH is permanent. The concrete durability and appearance improves with age.

Clean up: Clean all equipment with water only. Do not use thinners.

- Maintanance

Floors: Wash or wet mop with neutral or high pH detergent. Detergents must not contain caustic soda, sulfates or hydroxides. Acids and acidic cleaners will dull the surface sheen and/or

etch the surface.Walls: Flush with clean water.

- Special Consideration

- Do not use PENESEAL™ FH on extremely porous masonry, such as lightweight block

- Do not apply PENESEAL™ FH to frozen or freezing surfaces or when temperature falls below 40ºF (4ºC) or if temperatures will drop below freezing during the curing period (approximately 24 hours)

- Prevent PENESEAL™ FH from getting on glazed and finished surfaces such as glass, aluminum, etc. In case of contact, flush immediately with water

- Protect surfaces from equipment leaks or other leaks, such as oil, hydraulic fluid, etc.

- PENESEAL™ FH treated surfaces can become slippery during application. Exercise caution and wear appropriate footwear and protective clothing

- PENESEAL™ FH is not a vapor barrier

- Apply to colored concrete only after the slab is fully cured

Properties

- Color

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Abrasion (23°C, 50% Humidity) | 80.9 | % | ASTM C779 |

| Bonding (23°C, 50% Humidity) | 60.0 | % | ASTM D3359 |

| Curing (24 Hours, 23°C, 50% Humidity) | 61.0 | % | - |

| Hardening (23°C, 50% Humidity) | 40.0 | % | ASTM C39 |

| Impact Resistance (23°C, 50% Humidity) | 16.1 | % | ASTM C805 |

| Permeability (100 psi, 23°C, 50% Humidity) | 98.0 | % | - |

| Weathering (23°C, 50% Humidity) | No Adverse Effect | - | ASTM G23 |

| Coverage | 200.0 | sq.ft/gal | - |

Regulatory & Compliance

- Regulatory & Compliance

Complies with all VOC and USDA regulations.

Technical Details & Test Data

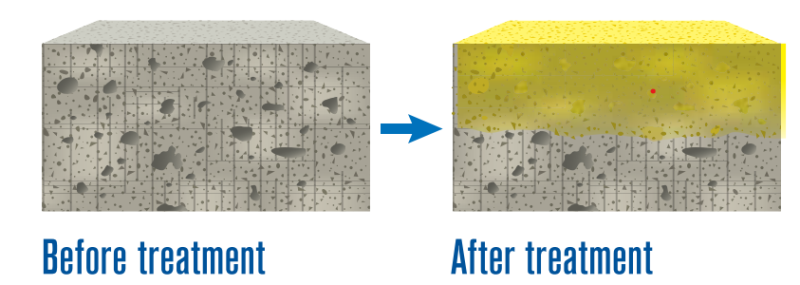

- Comparison

Safety & Health

- Waste Disposal

This material must be discarded or disposed of in accordance with all local, state, provincial, and federal regulations. The generation of waste should be avoided or minimized wherever possible.

Packaging & Availability

- Packaging

- 5-gallon (19-l) pails

- 55-gallon (208-l) drums

- 275-gallon (1041-l) containers

Storage & Handling

- Shelf Life / Storage

- 24 months from the date of manufacture, when unopened, undamaged original container is properly stored in a cool and dry place, unexposed to moisture and sunlight

- Always tightly reseal container after use

- Do not allow to freeze

- Caution

- Avoid contact with eyes and wear suitable protective eye wear

- Avoid prolonged or repeated contact with skin

- Wear gloves and suitable protective clothing

- Do not breathe dusts or mists

- Keep away from children