Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Base Chemicals Functions

- Technologies

- Product Families

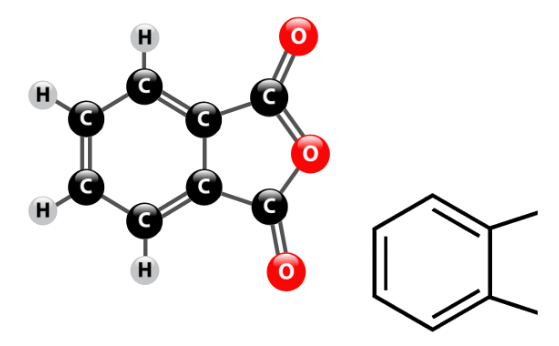

- Chemical Structure

Features & Benefits

- Product Highlights

Phthalate esters, which function as plasticizers, are derived from PAN. PAN has another major use in the production of polyester resins and other minor uses in the production of alkyd resins used in paints and lacquers, certain dyes, insect repellents and urethane polyester polyols. It has also been used as a rubber scorch inhibitor and retarder (HSDB, 1995; National Cancer Institute (NCI), 1979). PAN is a chemical intermediate that reacts readily and produces a broad range of products that process easily and give a wide range of performance characteristics at a low cost.

IGPL operates its plant based on the processes of the licensor M/s Wacker Chemie GmbH, Germany. The process is Wacker’s Von-Heyden’s Low Energy Process and the plant has been engineered by M/s Lurgi GmbH, Germany. Existing capacity of Phthalic Anydride is at 2,22,100 MTPA.

Applications & Uses

- Applications

- Usage

PAN is widely used in industry for the production of certain dyes. A well-known application of this reactivity is the preparation of the anthroquinone dye quinizarin. The primary use of PAN is as a chemical intermediate in the production of plastics from vinyl chloride.

Properties

- Appearance

- Snow White Free Flowing Flakes

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Color (Molten Material) | max. 20 | HU | ASTM-D-3366-95 Reapproved-2003 (APHA) |

| Color (Molten Material, 250°C, 90 Minutes) | max. 40 | HU | ASTM-D-3366-95 Reapproved-2003 (APHA) |

| Solidification Point | min. 130.8 | °C | ASTM-D-6875-12 |

| Purity (C₄H₂O₃, By GC) | min. 99.8 | wt.% | WI/QCL/043 |

| Maleic Anhydride & Other Oxidisable Impurities expressed as C₄H₂O₃ | max. 0.05 | wt.% | WI/QCL/043 |

| Acid Value | 753 - 763 | mg of KOH/gm | WI/QCL/043 |