Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Description

IGP-HWFclassic 5907 is a logical further development of the established IGP-HWFclassic product range for highly weather-resistant architectural applications, based on saturated polyester resins and declaration-free hardener.

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Application

- Metal facade

- Window and door profiles

- Sun and weather protection elements

- Street furniture

- Infrastructural facilities

- Cleaning

Coated parts to be cleaned in compliance with the regulations RAL-GZ 632 or SZFF 61.01. For pearl-mica effect, the Technical Information IGP-TI 106 must also be observed.

- Stripping and Subsequent Use Phase

After use, coated goods should be supplied to the normal recycling process. The disposal methods for sludges or residual powders must be observed in accordance with the local official provisions whilst taking Waste Code “080201 Coating Powder Wastes” in accordance with the European Waste Catalog into consideration.

Properties

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Cross-Cut Adhesion Test | Gt 0 | - | DIN EN ISO 2409 |

| Mandrel Bending Test | max.5 | mm | DIN EN ISO 1519 |

| Impact Penetration | min. 20 | nchp. | ASTM D2794 |

| Erichsen Cupping | min. 5 | mm | DIN EN ISO 1520 |

| Buchholz Hardness | max.84 | - | DIN EN ISO 2815 |

| Value | Units | Test Method / Conditions | |

| Particle Size | max.100 | μm | - |

| Solids Approx. | 99 | % | - |

| Density According to Shade | 1.2 -1.6 | kg/l | - |

| Suitability for Storage | 24 months | - | - |

| Storage Temperature | max.25 | °C | - |

| Robustness | min. 50 | % | AA341.62 |

| Weathering (Long-term exposure, 3 year Florida, 5° south, residual gloss) | min. 50 | % | DIN EN ISO 2810 |

| Weathering (Accelerated weathering test, WOM 1000h) | min. 90 | % | DIN EN ISO 16474-3 |

Regulatory & Compliance

- Material Approval

- Qualicoat No. P-0540, class 1

- Qualicoat No. P-1735, class 1

- GSB No.: 109 m, class “standard” AAMA 2603-15, independent inspection documentation

- Blasted bright steel - Qualisteelcoat: PE-0015 with Korroprimer 1001, PE-0016 with Korroprimer 6007

- Galvanized and swept steel - Qualisteelcoat: PE-0017 with Korroprimer 1001, PE-0018 with Korroprimer 6007

Technical Details & Test Data

- Stoving Conditions

Time and temperature combinations that result in an ideal cross-linking of the coat are displayed.

Retention time at object temperature Object temperature Minimum Maximum 170°C 20 min. 30 min. 180°C 15 min. 25 min. 190°C 10 min. 20 min. - Test Conditions

To determine the following data, IGP-HWFclassic 5907 was applied as follows:

- Alu sheet (AlMg1 H14 or "Q-Panel AA 5005-H24")0.8 mm, chrome-free

- Coating thickness 60 μm

- Object temperature of 170°C, 20 min.

- Chemical Tests

1000h condensate water test, DIN EN ISO 6270-2 No infiltration, No blisters 1000h salt spray test, DIN EN ISO 9227 No infiltration, No blisters Mortar resistance, ASTM D 3260 Easily removable after 24h with no residues - Processing Information

Pre-treatment

The substrate to be coated must be fr ee of oxidation products, or residue from scale, oil, grease or release agents. Depending on application range and the planned usage duration, a pre-treatment suitable for the substrate is used:

- Aluminum substrate:

- Chrome-free pre-treatment: Preferred approved systems from GSB and Qualicoat

- Chromatising: DIN EN 12487

- Pre-anodisation: Also available

Steel substrate

- Zinc or iron (Fe) phosphating

- Galvanized sheet metal: Chromatising in accordance with DIN EN 12487

For improved corrosion protection for applications on steel / galvanized steel, the use of corr osion protection primer IGP-KORROPRIMER 10 is recommended. The suitability of the pre-treatment method used is generally to be tested by the coater in advance with appropriate test methods. The minimum requirement for aluminum substrates / galvanized steel components intended for architectural applications is performing a boil test / pressure cooker test with a subsequent crosscut adhesion and pull-off test. We refer to the guidelines of the GSB certifications and Qualicoat. For further information: see also our special leaflet on pre-treatment (IGP-TI 100).

Coating equipment

All commercially available electrostatic systems, both corona and Tribo charge systems. Exceptions are Pearl Mica and Crystal Color effects which must be processed only with corona charging. For the construction and operation of powder coating plants, the following regulations must be complied with: ATEX RL 2014/34/EU, EN 50177, DIN EN 16985.

Recyclability

Small proportions of recycled powder should be added, automatically if possible, to the fresh powder. For Pearl Mica effects, refer also to processing instruction VR 201.

- Aluminum substrate:

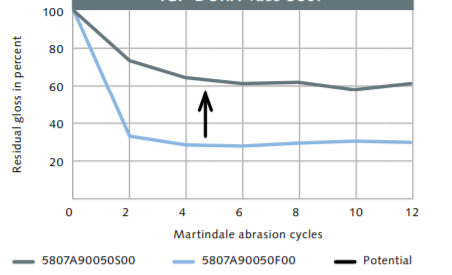

- Martindale Measurement Results for IGP-DURA®face 5807

Packaging & Availability

- Product Range

5907A Uni, smooth finish, silk gloss IGP-DURA®clean effect

5907E Pearl mica effect, smooth finish, silk gloss IGP-DURA®clean effect

Gloss, DIN EN ISO 2813: 65-85 R‘/60°

Shades: Due to the limited selection of highly weather-resistant pigments, the line includes a lower number of achievable and approved shades corresponding to the special IGP color chart. If you have a special color request for a highly weather-resistant powder coating finish, please contact our customer laboratory.

- Packing

- Carton with inserted antistatic PE liner, content 20 kg

- Carton container with 25 antistatic PE liners, content 500 kg

Storage & Handling

- Weathering

Accelerated weathering test,1000h DIN EN ISO 16474-2 > 90% residual gloss

Long-term exposure, 3 year Florida, 5° south, DIN EN ISO 2810 > 50% residual gloss

- Suitability for Storage

24 months