Knowde Enhanced TDS

Identification & Functionality

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Characteristics

- Economic

- Reusable

- Food approved

- Easily processable

- Washable

- Insulating

- High rigidity

- Sterilisable

- Shockproof

- Strong and durable

- Good rupture and tear resistance

- Possible to laminate

- Dust and fiber free

- Ecological

- Water and moisture resistant

- Good chemical resistance

- High compression strength

- Light-weight

- Soundproof

- Smooth top and bottom layer

- Product Highlights

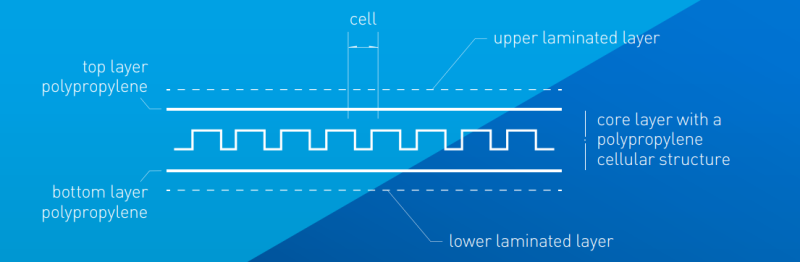

- Triacell® is an extruded polypropylene sheet consisting of 3 layers. The central layer is a cell structured layer. The top and bottom layers are 2 smooth layers. The cell structure is the core of this sheet. This gives Triacell® its principal characteristics: a high rigidity and a high compression strength, combined with a light weight.

- The smooth upper and lower layer make this sheet perfectly suitable for printing. The possibility to laminate this sheet enlarges the applications.

- Triacell® can be processed into packaging, layer pads, product dividers.

Applications & Uses

- Markets

- Plastics & Elastomers Processing Methods

- Possible Processing

- Cutting

- Die cutting

- Welding

- Bonding

- Sterilizing

- Recycling

- Printing

- Possible Treatments

- Flame retardant

- UV stabilizer

- Antistatic

- Corona treatment

- Applications

Protective packaging, container sleeves, construction applications, displays, pallet protection, floor and wall panels (exhibition stands), boxes, dividers, covering of cargo spaces.

Properties

- Mechanical Properties

- Physical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Compresaion Resistance (at 1000N, 2,4mm/450g) | max. 30 | N/cm² | External Lab |

| Compresaion Resistance (at 1000N, 2,7mm/600g) | max. 30 | N/cm² | External Lab |

| Compresaion Resistance (at 1000N, 3,4mm/900g) | max. 20 | N/cm² | External Lab |

| Compresaion Resistance (at 1000N, 5,7mm/1600g) | max. 15 | N/cm² | External Lab |

| Flexural Break Resistance (2,4mm/450g) | 3,75 | N/mm² | ISO 178 |

| Flexural Break Resistance (2,7mm/600g) | 3.2 | N/mm² | ISO 178 |

| Flexural Break Resistance (3,4mm/900g) | 8.28 | N/mm² | ISO 178 |

| Flexural Break Resistance (5,7mm/1600g) | 27.4 | N/mm² | ISO 178 |

| Flexural Modulus | 1350 | MPa | ISO 178 |

| Impact Resistance (2,4mm/450g) | No Effect max. 0.30m | — | Falling Dart Drop |

| Impact Resistance (2,7mm/600g ) | No Effect max. 0.40m | — | Falling Dart Drop |

| Impact Resistance (3,4mm/900g) | No Effect max. 0.80m | — | Falling Dart Drop |

| Impact Resistance (5,7mm/1600g) | No Effect max. 1.00m | — | Falling Dart Drop |

| Impact Strength Izod (-20°C) | 0 - 6 | kJ/m² | ISO 180 |

| Impact Strength Izod (23°C) | 5 - 25 | kJ/m² | ISO 180 |

| Tensile Strength (50 Mm/Min) | 27-33 | MPa | ISO 527-2 |

| Value | Units | Test Method / Conditions | |

| Specific Gravity | 0.907 | g/cm³ | ISO 1183 |

| Water Absorption | 0.02 | % | ISO 62 |

| Value | Units | Test Method / Conditions | |

| Coefficient of Linear Expansion | 0.18 | mm/m°C | ASTMD696 |

| Heat Deflection Temp. (0,46 Mpa) | 78 | °C | ISO 75 |

| Heat Deflection Temp. (1,82 Mpa) | 52 | °C | ISO 75 |

| Specific Heat | 1.68 | J/g°C | DSC |

| Vicat Softening Point (1 Kg, 10N) | 148 | °C | ISO 306 |

| Vicat Softening Point (5 Kg, 50N) | 78 | °C | ISO 306 |

| Value | Units | Test Method / Conditions | |

| Dielectric Constant (At 1 Mhz) | 2.25 | — | ASTMD150 |

| Dielectric Strength (500V/Sec) | 70 | kV/mm | ASTMD149 |

| Dissipation Factor (Tgd At 1Mhz) | max. 5 x 10^-4 | — | ASTMD150 |

| Surface Resistivity | Ca. 10^13 | Ω | ASTMD257 |