Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Product Type

- Biodegradable

- Yes

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Features

• Avoid musculoskeletal and slippage related injuries

• Increase production rates

• Achieve closer fits

• Reduce part rejects

• Improve product performance

• Reduce installation forces

• Biodegradable

• Non-flammable, non-toxic, non-corrosive

Applications & Uses

- Applications

- Application Method

- Compatible Substrates & Surfaces

- Recommended Uses

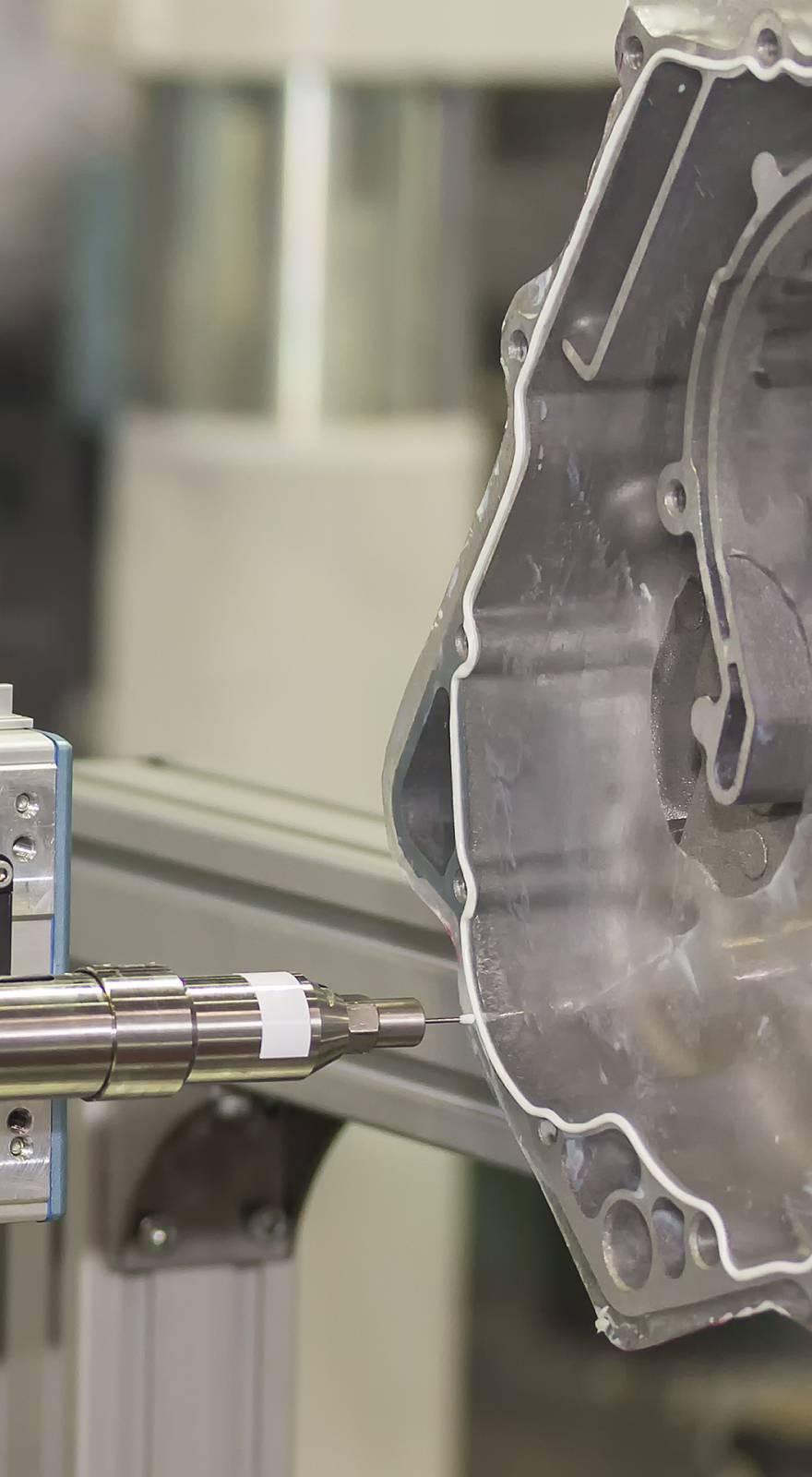

P-80® Emulsion Temporary Rubber Assembly

Lubricant is used to install hoses, tires, O-rings,

seals, bushings, gaskets, grommets, grips, and

many other rubber and plastic parts.- How To Apply

P-80® Emulsion can be applied using automated systems or manually by dip, brush, sponge, or spray techniques.

Properties

- Physical Form

- Appearance

- Milky white to beige

- Odor

- Mild

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Description | Synthetic esters emulsified in water | — | — |

| pH Value | 8.4 | — | — |

| Viscosity (at 25°C) | 150.0 | cps | — |

| Estimated dry time | min. 1 | hour | — |

| Sprayable | Yes | — | — |

| Reduction in friction | approx. 70 | % | — |

| Freezing point | 0.0 | °C | — |

| Flash point | None | — | — |

| Storage temperature | 2˚ – 30˚ | °C | — |

| Specific gravity | 0.98 | — | — |

| Prop 65 | Exempt | — | — |

| VOC by Volume | 0.7 | % | — |

Regulatory & Compliance

- Certifications & Compliance

- Environmental Compliance

Complies with RoHS and REACH (SVHC: none). Cobalt-free; Conflict mineral-free

Safety & Health

- Sewage Disposal

Contents may be disposed of according to local, state and federal regulations. Completely emptied

packages can be recycled.

Packaging & Availability

- Packaging Type

- P-80® Emulsion Sizes Available

- P-5311-100 10 mL tube (100 per case)

- P-5318 112 mL bottles (136 per case)

- P-5391-06 475 mL container (6 per case)

- P-5391-06-SPR 475 mL container w/ spray tops (6 per case)

- P-5391-12 475 mL container (12 per case)

- P-5391-12-SPR 475 mL container w/ spray tops (12 per case)

- P-5321-12 1 liter container (12 per case)

- P-5322-04 4 liter container (4 per case)

- P-5394 19.0 kg net wt. container

- P-5396 200 kg net wt. plastic drum

- P-5398 1,000 kg net wt. plastic tote

Spray tops available separately to fit 1-Liter and 475 mL bottles

Storage & Handling

- Handling

Before dispensing P-80® Emulsion from drums, mix with a clean recirculation pump or folding propeller

mixer for 5 minutes to ensure a homogenous mixture is drawn off. If a hold tank is used, agitate the

lubricant before it is fed to assembly equipment. Smaller containers should be shaken or stirred prior to

use. Never use air agitation. Bubbling compressed air through P-80® lubricants may cause separation or

spoilage. Do not mix P-80® Emulsion with other chemicals. Do not dilute with water. Store P-80® Emulsion

in a sealed container when not in use. Do not pour dispensed product back into the original container.

Use at room temperature.- Storage

Do not freeze. P-80® Emulsion should be stored at temperatures between 2˚ – 30˚C (36˚ – 86˚F) in the

original sealed container. Do not store outdoors in direct sunlight during warm weather. The shelf life of

P-80® Emulsion is 2 years from the manufacturing date.