Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Core Type

- Composite Materials Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Applications

- Composites End Use

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Strength | 150 | psi | — |

| Density | 6 | pcf | — |

| K-Factor | 80 | BTU in/hr ft °F. | ASTM D-256 |

| Modulus of Elasticity | 5000 | psi | — |

| Shear Strength | 100 | pcf | — |

| Tensile Strength | 180 | psi | — |

Technical Details & Test Data

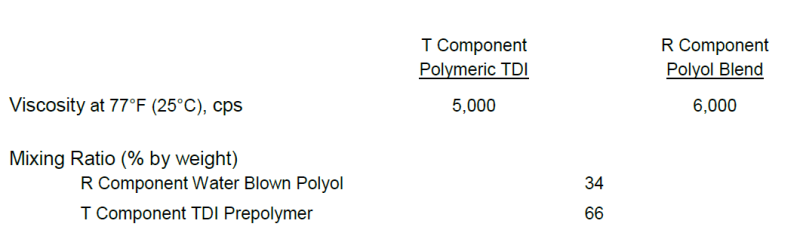

- Typical Chemical Properties

- Processing Parameters

Blend T component into R component. Mix for approximately 50 seconds using a high speed drill motor (3,500 rpm) Pour contents into mold preheated to 120°F. When foaming action has ceased post cure immediately. Cure one-half hour at ambient temperature and then one hour at 200°F. Cool mold to 100-130°F before stripping from mold.

Safety & Health

- Health and Safety Information

Safety Data Sheets are available which provide information concerning the health and safety precautions that must be observed when handling this product. Before working with this product, you must read and become familiar with the available information on the risks involved, proper use, and handing. All polyurethane foam burns in varying degrees, which in turn liberates toxic gasses; the foam should be evaluated in its final form for compliance to existing standards in your industry. Nothing contained herein grants or extends a license, express or implied, in connection with patents, issued or pending, of the manufacturer or others. The information contained herein is based on the manufacturer's own study and the works of others. The manufacturer makes no warranties, expressed or implied, as to the accuracy, completeness, or adequacy of the information contained herein. The manufacturer shall not be liable (regardless of fault) to the vendee's employees, or anyone for any direct, special or consequential damages arising out of or in connection with the accuracy, completeness, adequacy or furnishing of such information.

Storage & Handling

- Storage

Avoid moisture contamination during storage, handling, and processing. Store the polyol and isocyanate components from 65°F to 85°F. Do not expose isocyanate component to lower temperatures as freezing may occur

- Shelf Life

The shelf life is 12 months if stored in original unopened containers