Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Features

Excellent chemical and stress-crack resistance

Excellent impact strength

Good rigidity

Good melt strength

Meets Philippine FDA food

contact requirements

Halal-certified

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Typical Applications

Industrial chemical containers

Jerry cans for cooking oil and

water

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Charpy Impact Strength (23°C) | 87 | J/m | ASTM D6110 |

| ESCR (FED) | min. 700 | Hours | ASTM 01693 |

| Density (23°C) | 0.952 | g/cm³ | ASTM D792 |

| Elongation at Break (50 mm/min) | 1134 | % | ASTM D638 |

| Elongation at Yield (50 mm/min) | 16 | % | ASTM D638 |

| ESCR, F₅₀ (Condition B, 10% Igepal, 50°C) | min. 700 | Hours | ASTM 01693 |

| Flexural Modulus (1% Secant, 1.3 mm/min) | 1133 | MPa | ASTM D790 |

| Flow Index (190°C/21.6 kg) | 9 | g/10 min. | ASTM D1238 |

| Hardness | 62 | Shore D | ASTM D2240 |

| Heat Deflection Temperature (0.455 MPa) | 71 | °C | ASTM D648 |

| Melt Index (190°C/2.16 kg) | 0.075 | g/10 min. | ASTM D 1238 |

| Notched Izod Impact Strength (23°C) | No Break | J/m | ASTM D256 |

| Tensile Modulus (1% Secant, 5 mm/min) | 1698 | MPa | ASTM D638 |

| Tensile Strength at Break (50 mm/min) | 17 | MPa | ASTM D638 |

| Tensile Strength at Yield (50 mm/min) | 25 | MPa | ASTM D638 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

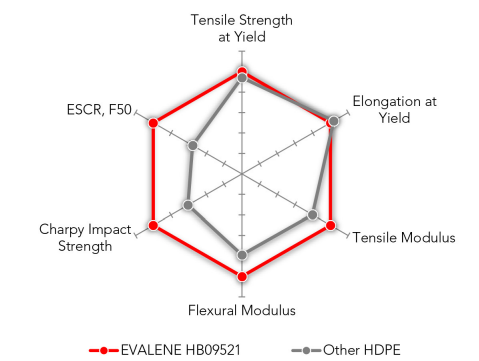

- Resin Property Performance