Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Features

High stiffness

Good puncture resistance

Good moisture barrier properties

Meets FDA Philippines

food-contact requirements

Halal certified

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Typical Applications

Produce bags on a roll

Supermarket produce bags

Wet market bags

Sando bags

Laundry bags

Carrier bags

Trash bags

Sack liners

Flexible packaging

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Dart Drop Impact Strength | 183 | g | ASTM D1709 |

| Density (23°C) | 0.952 | g/cm³ | ASTM D1505 |

| Elmendorf Tear Strength | 20/395 | g | ASTM D1922 |

| Elongation at Break (500 mm/min) | 195 / 304 | % | ASTM D882 |

| Elongation at Yield (500 mm/min) | 12 / 6 | % | ASTM D882 |

| Flow Index (190°C/21.6 kg) | 14 | g/10 min. | ASTM D1238 |

| Melt Index (190°C/2.16 kg) | 0.12 | g/10 min | ASTM D1238 |

| Tensile Modulus (1% Secant, 25 mm/min) | 744 / 931 | MPa | ASTM D882 |

| Tensile Strength at Break (500 mm/min) | 32 / 18 | MPa | ASTM D882 |

| Tensile Strength at Yield (500 mm/min) | 30/25 | MPa | ASTM D882 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

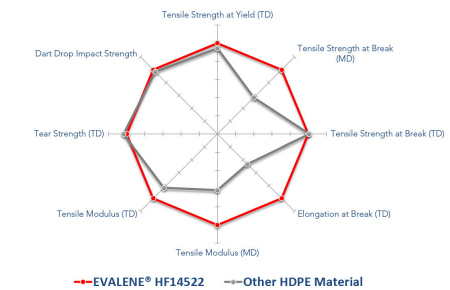

- Mechanical property of EVALENE HF14522 vs. other HDPE material

EVALENE HF14522 has at least 17% higher tensile modulus than the other HDPE material. This means that a film made with EVALENE HF14522 feels sitter, a distinct advantage tor the producer of thin films because the end- user prefers film which feels stiff when handled. Additionally, EVALENE HE14522s superior tensile strength at break in the machine direction, 43% higher than the other HDPE material, is an obvious benefit. EVALENE HF14522s clear edge in tensile strength, coupled with comparable dart drop impact strength and tear strength as the other HDPE material, gives it a good stiffness-toughness balance which makes this EVALENE grade ideal for film applications as thin as 5 microns (0.0002") - a genuine downgauging benefit.