Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Features

Good throughputs

Excellent balance of tenacity

and stretchability

Meets Philippine FDA food

contact requirements

Halal-certified

Applications & Uses

- Applications

- Composites End Use

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Typical Applications

Commercial and industrial ropes

and nets (fishing net, agricultural

net, mosquito net)

Non-woven filament applications

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density (23°C) | 956 | g/cm³ | ASTM D1505 |

| Elongation at Break (50 mm/min) | 1119 | % | ASTM D638 |

| Elongation at Yield (50 mm/min) | 21 | % | ASTM D638 |

| Flexural Modulus (1% Secant, 1.3 mm/min) | 715 | MPa | ASTM D790 |

| Melt Index (190°C/2.16 kg) | 1 | g/10 min | ASTM D1238 |

| Tensile Modulus (1% Secant, 5 mm/min) | 1274 | MPa | ASTM D638 |

| Tensile Strength at Break (50 mm/min) | 20 | MPa | ASTM D638 |

| Tensile Strength at Yield (50 mm/min) | 26 | MPa | ASTM D638 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

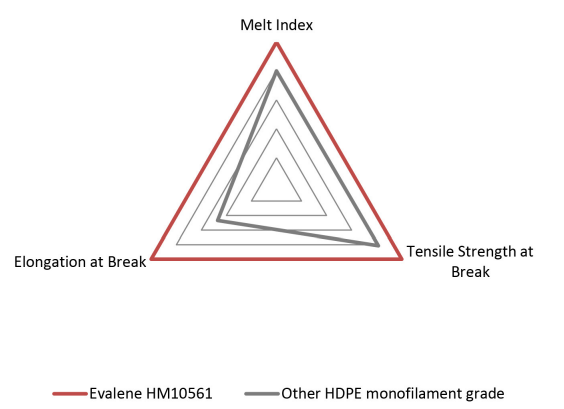

- Resin Property Comparison

EVALENE® HM10561's higher melt index results in (1) higher extruder throughputs for the same extrusion temperatures or (2) less energy requirement for the same extruder throughput.

EVALENE® HM10561's higher elongation and tensile strength at break allow for stretch ratios with corresponding higher tenacities.