Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

Features & Benefits

- Industrial Additives Features

- Benefits

High Fermentable Content

- High organic content (over 95%) provides up to 30% more fermentables than standard emulsified vegetable oils.

Easy Material Handling- Low viscosity; readily mixes with water; no high shear mixing needed

- Low injection pressure.

- Longer shelf life

Increased Subsurface Distribution- Thermodynamically stable

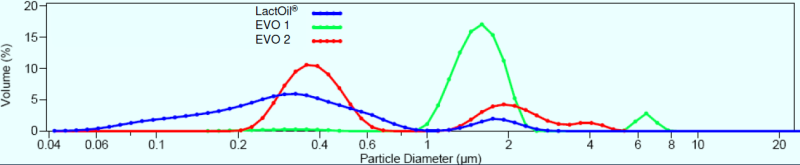

- Small particle size

- Average particle size < 1 micron

- High emulsion stability allows for greater subsurface transport

Increased Degradation Rates- Provides sustained lactate for accelerated metabolism

Higher Efficiency- Increased contaminant degradation per unit of fermentable product injected as compared to standard EVO

Contaminants Treated- Chlorinated solvents, nitrates, perchlorate, RDX, metals, trichloropropane, mine impacted water

Treatment Applications- Permanent wells, direct push, excavation backfill, bedrock

Applications & Uses

- Applicable Processes

- Uses

Contaminants Treated

- Chlorinated solvents

- Perchlorate

- RDX

- Reduction of metals

Treatment Configurations- Source area treatment

- Biobarrier treatment

- Plume-wide treatment

Delivery Methods- Permanent injection wells

- Direct push methods

Properties

- Miscible in

- Water, Self emulsifies

- Typical Properties

- Viscosity

Temperatures below 50°F will cause the material to become more viscose, and may solidify to the consistency of bacon grease. If this should happen, move the material to a warmer location and mix.

| Value | Units | Test Method / Conditions | |

| pH (Buffered to) | min. 6.5 | - | - |

| Specific Gravity (at 20°C) | 0.95 | - | - |

| Zeta Potential | -83.0 | mV | - |

| Particle Size | max. 1 | microns | - |

| Viscosity (at 70°F) | 25.0 | cPs | - |

Technical Details & Test Data

- Microcosm Study results

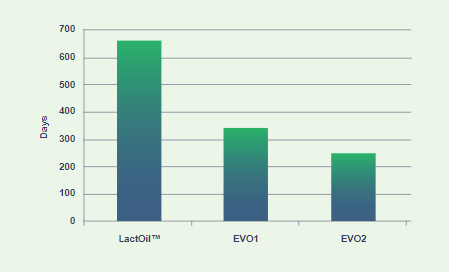

Longevity : LactOil® has an estimated electron donor longevity that is 2-3 times greater than other commercially available emulsified vegetable products.

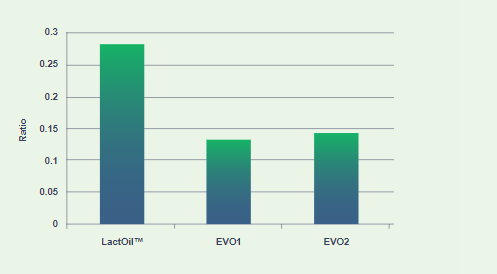

Efficiency : When compared to other commercially available emulsified vegetable oil products, LactOil® has a higher ratio of electrons stimulating dechlorination than consumed by methanogenesis and acetogenesis.

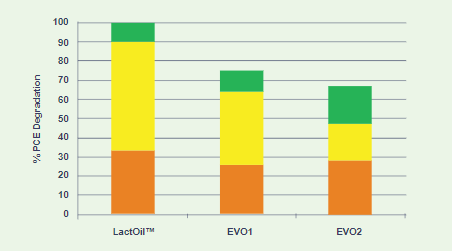

Kinetics : LactOil® can degrade PCE to cis-DCE, vinyl chloride, and ethene quicker than other commercially available emulsified vegetable oil products.

Particle Size Analysis : A particle size analysis shows LactOil® particles are consistently smaller than 1 micron. Small particle size and stability allow for physical transport of material in the aquifer.

Packaging & Availability

- Packaging Type

- Packaging Information

- 5-gallon pails

- 55-gallon polyethylene drums

- 265-gallon IBC totes

- Tankers

Storage & Handling

- Storage & Handling Information

- Store unopened under dry conditions at temperatures between 50°F and 85°F.

- Diluted product should be used within 3 days to avoid microbial growth and activity which may cause gas buildups in containers and visible growth which may foul equipment.

- Following injection of material, wells should be flushed with clean water to prevent microbial growth.