Knowde Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- Chemical Name

- CAS No.

- 72-17-3

- EC No.

- 200-772-0

- Technologies

Features & Benefits

- Industrial Additives Features

- Benefits of Wilclear®

- Provides carbon for rapid establishment of anaerobic conditions needed for reduction of nitrate, hexavalent chromium, perchlorate, and RDX.

- Miscibility in water and low viscosity allow for advective transport with groundwater; enhancing subsurface distribution and minimizing the number of injection points.

- Effective for both dissolved phase and DNAPL source area treatment.

- Benefits

- Proven : Lactate is a proven technology and one of the most efficient electron donors available.

- Fast : Lactate rapidly establishes anaerobic conditions needed for dechlorination.

- Effective : Lactate provides the perfect concentration of hydrogen needed for rapid dechlorination.

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Uses

Contaminants Treated

- Chlorinated solvents

- Perchlorate

- RDX

- Reduction of metals

Treatment Configurations- Permanent injection wells

- Direct push methods

Delivery Methods- Permanent injection wells

- Direct push methods

Properties

- Physical Form

- Soluble in

- Water

- Typical Properties

| Value | Units | Test Method / Conditions | |

| WILCLEAR® Sodium Lactate Content | 58.8 - 61.2 | % wt/wt | — |

| pH | 6 - 8 | — | — |

| Viscosity (at 20°C) | 110.0 | cPs | — |

| Specific Gravity | 1.32 - 1.35 | — | — |

| Assay (Sodium) | 12 - 12.6 | % wt/wt | — |

| Water Content | 38.8 - 41.2 | % wt/wt | — |

Technical Details & Test Data

- Rapid Dechlorination Kinetics

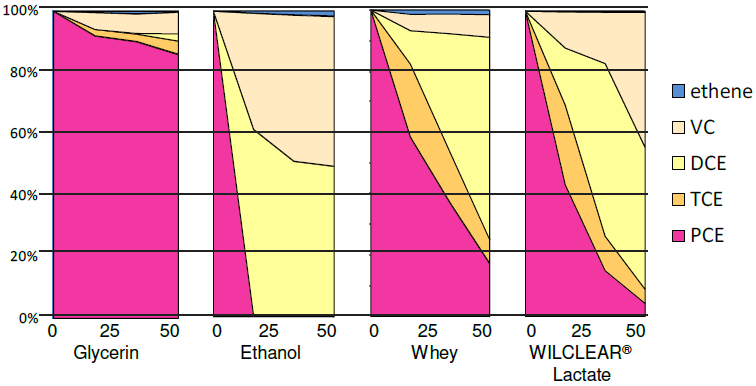

Microcosm studies comparing WILCLEAR® to other soluble donors show that while all four donors stimulate complete dechlorination of PCE to ethene, WILCLEAR® and ethanol have the fastest dechlorination kinetics.

- Greater Donor Efficiency

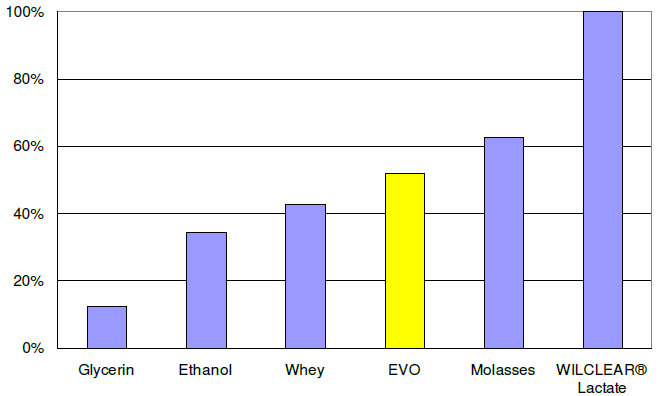

Efficiency (amount of contaminant remediated per unit donor added) should be considered when determining donor cost performance. Of the three donors that show both complete dechlorination and reasonable remediation rates, lactate has the best efficiency.

Packaging & Availability

- Packaging Type

- Packaging Information

- 5-gallon pails (55lbs)

- 55-gallon polyethylene drums (606lbs)

- 265-gallon IBC totes (2899 lbs)

- Tankers

Storage & Handling

- Shelf Life

- 2 Years (Unopened)

- Storage and Shelf Life

- Store unopened under dry conditions at temperatures between 35°F and 85°F.

- The shelf life of the unopened products is 2 years

- The opened product should be used within 30 days

- Diluted products should be used within 5 days to avoid microbial growth and activity which may cause gas buildups in containers and visible growth which may foul equipment.

- Following injection of material, wells should be flushed with clean water to prevent microbial growth.

- Equipment decontamination should follow site-specific requirements. In most situations, any product residual should be flushed into the aquifer and then chased with clean water.