Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Technologies

- Product Families

- Composition

Quality sealers are composed of film forming resins or binders that provides the wear, durability, and chemical resistance; pigments (when desired) provide color; and thinners that evaporate but are needed to make an easily applied liquid material. The difference between ordinary sealers and floor paints is the amount and type of resin or film former used. Typically, sealers contain anywhere from 150-200% or more film formers than paint. This is why a properly applied floor sealer will outlast a properly applied paint.

Features & Benefits

- Ready-to-Use Product Features

- Features

Meets OTC requirements

Highest Quality

No Acid Etching or Sandblasting Required Under

Normal Conditions

Chemical & Abrasion Resistant

Simple Application

Adheres Over Rubber-Based Curing Compounds

Floor May Be Damp during Application

Semi-Gloss: Specular Gloss 40%

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Uses

SureSeal OTC provides a long-wearing film to protect the floors from abuse, from a wide variety of foot and vehicular traffic, chemicals, etc. It reduces dusting of a concrete floor to provide a clean atmosphere in which to work. Inventory and equipment stay clean and look better. Maintenance is considerably reduced, since dirt stays on the surface for easy removal. Use it in schools, offices, hospitals, clubs, warehouses, manufacturing plants, and commercial office buildings. When used on floors to receive tile or carpet, SureSeal OTC reduces the quantity of adhesive necessary.

- Coverage Rate

Apply 2-3 coats at 400-600 ft2/gallon per coat.

- Directions

Surface Preparation: The satisfactory performance of any coating system is directly related to the preparation taken to the surface to be coated. Only apply to sound, clean surfaces. Surfaces should be cleaned thoroughly. Remove all dust, wax, grease, oil and all foreign matter according to ASTM D-4258. If smooth, dense troweled concrete, then sand blasting and mechanical scarification according to ASTM D-4259 are the preferred methods of properly preparing the floor and removing laitance.

Acid etching as per ASTM D-4260 with a 15-20% muriatic acid solution can be used. Be sure to rinse thoroughly with clean water to remove residue.

Application: Stir pigmented SureSeal OTC before use. Apply by brush, roller, or paint sprayer. Test small area first for correct application procedures. On rough surfaces, use a long nap roller. Thin the first coat by up to 15% with SAC. Apply 2-3 coats at 300-500 ft2/gallon. Allow each coat to dry before applying subsequent coats. The use of spiked rollers helps to reduce bubbles in film.

Non-Slip Surface: When a non-slip surface is desired, sprinkle approximately .25 lbs./ft2 of SurePoxy Mortar Aggregate on the surface of the first coat while the coating is still wet. After the coating dries, sweep off loose material to save for reuse, then apply the second coat.

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| VOC (Clear) | 335.0 | grams/liter | — |

| VOC (Pigmented) | 295 - 325 | grams/liter | — |

Technical Details & Test Data

- Abrasion Resistance Test

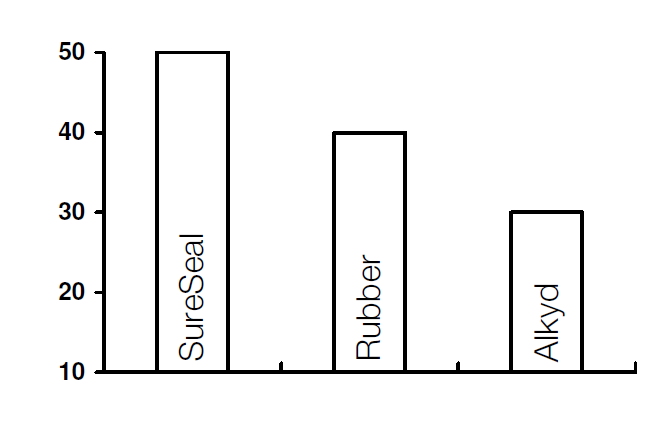

Liters falling sand to remove 1 mil.

- Chemical Resistance Chart

Reagent Concentration SureSeal Water 100 OK Oils (Motor, mineral vegetable, peanut) 100 OK Detergent Solution 5 OK Ammonium Hydroxide 50 OK Ammonia 100 OK Sodium Hydroxide 50 OK Sodium Chloride 20 OK Calcium Chloride 20 OK Ferric Chloride 20 OK Sodium Carbonate 50 OK Chlorine Water 5 OK Hydrochloric Acid 10 NR Acetic Acid 99 OK Nitric Acid 10 NR Nitric Acid 50 NR Phosphoric Acid 10 OK Sulphuric Acid 96 NR Sulphuric Acid 10 OK Sea Water 100 OK Sugar Solution 10 OK Skydrol 500 A 100 NR Aliphatic Solvents 100 Softens Aromatic Solvents 100 NR Alcohols 100 OK Ketones 100 NR Gasoline 100 NR Spillage at room temperature

*Loss of gloss

NR – Not Recommended

- Technical Information

Test results were achieved under laboratory conditions. Statistical variations will occur based upon mixing methods, temperature & humidity, test methodology, site conditions, curing conditions, application methods, and equipment.

Safety & Health

- Precautions

Not designed for immersion in strong chemicals or prolonged exposure to gas. All coatings can be slippery when wet. If intended to be used in areas that will be wet, follow the above directions for non-slip surfaces. Allow coating to properly cure for 5-7 days before subjecting it to hard use. Extremely dense, smooth floors should be etched before applying SureSeal OTC. Clear sealers produce an uneven gloss, due to uneven porosity of concrete clear sealer dries with an amber coat. Do not apply SureSeal where chemical resistance tests show it not to be recommended. Never apply over contaminated surfaces. Read Safety Data Sheet before using.

Packaging & Availability

- Packaging

5 gallon pail

55 gallon drum (clear only)