Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- EC No.

- 269-105-9

- Technologies

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Materials Features

- Product Highlights

- The StanoStat CPM range are deep blue colored antimony tin oxides with a unique set of properties.

- CPM oxides in bulk are aggregates, consisting of nano-sized, spherical primary particles. This allows the products to be micronised in a variety of aqueous and organic solvents to nano-dispersions, which can be integrated into highly transparent, nearly colorless coatings. CPM oxides provide a high electrical conductivity and an excellent absorption of infrared light.

- Advantage

- Strong NIR absorber with primary particles in nanoscale

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Coating Type

- Composites End Use

- Ink & Toner Type

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application

- The CPM nanoparticles find applications in areas where the functionality must meet a requirement for transparency.

- CPM nanoparticles offer a higher degree of infrared absorption than the CP grades. The dispersions in water or solvents are used for the formulation of coatings, and inks for film coating. In high end solar control films for automotive and residential applications, or in agricultural films in combination with other additives, CPM materials provide an efficient IR absorption at an excellent price to performance ratio. Polymer films are not the only possible substrate, coating on glass or ceramics is also possible.

- At higher loadings, transparent antistatic coatings can be achieved. For example, to speed up printing processes on polymer films or for dust prevention on solar cells. The high thermal stability of CPM oxides allows antistatic glazes to be formulated for ceramic applications.

- For brand protection, CPM materials allow the creation of invisible watermark-like imprints.

- The high IR absorption is used for reheating applications in PET processing, as well as in emerging technologies such as 3D printing or powder sintering.

Properties

- Appearance

- Blue-grey powder comprising aggregates of nanosized spherical primary particles.

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Primary Crystallite Size | 10 | nanometres | — |

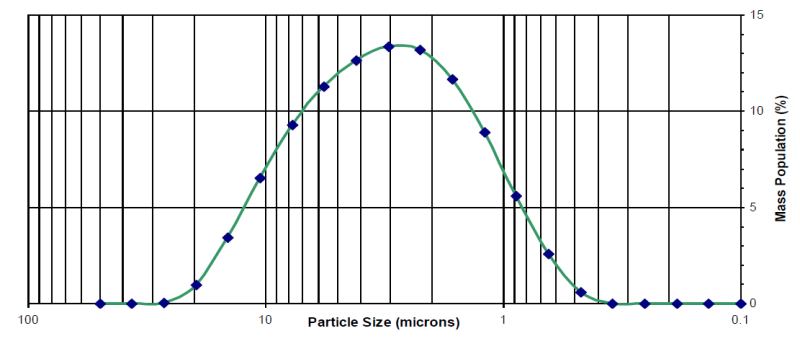

| Particle Size (D10%) | 0.7 | microns | Malvern Mastersizer |

| Particle Size (D50%) | 2.6 | microns | Malvern Mastersizer |

| Particle Size (D90%) | 9 | microns | Malvern Mastersizer |

| Powder Resistivity | 0.3 | Ohm. cm | — |

| Surface Area | 50 | m²/g | BET |

| Specific Gravity | 6.5 | — | — |

| Bulk Density | 1400 | g/l | — |

| Tapped Density | 1500 | g/l | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Particle Size Distribution

StanoStat CPM10C Powder can be used to produce stable water-based colloidal dispersions for use in the preparation of transparent electrically conductive and infrared reflective thin films.

Dispersions can contain up to 30 % w/w solids and consist of agglomerates of particles with a primary particle size of the order of 10 nm.

Water-based or solvent-based nanoparticulate dispersions produced from StanoStat

CPM10C can be formulated into inks for ink-jet printing or spin-coating, producing good

quality thin films with low haze.Transparent thin film coatings of nominally 400nm film thickness were prepared from

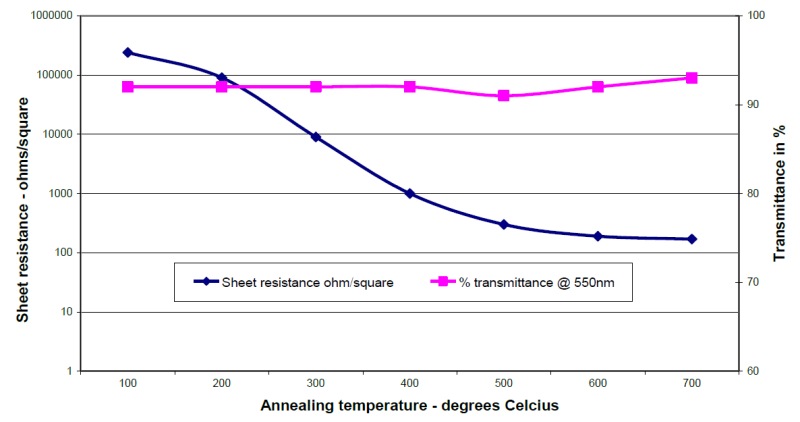

typical dispersions onto Corning Eagle 2000™ glass.The chart below shows the effect of annealing in air on sheet resistance for a conductive ink formulated with 10% CPM10C and 0.2 % addition of surfactant.

Effect of annealing temperature on sheet resistance and optical transmittance :

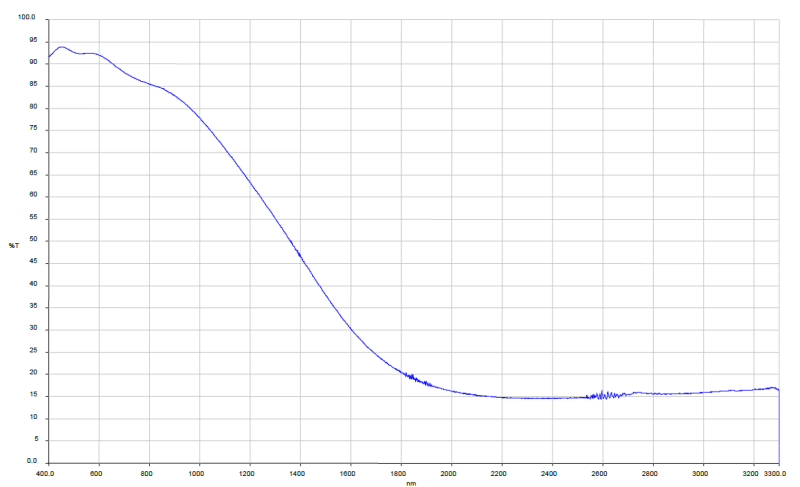

Spectral performance - CPM10C coating on Corning Eagle 2000™ glass :

Comments: Eagle 2000 ATO coated glass (OAN1568/1) vs uncoated glass (OAN1568/2)