Knowde Enhanced TDS

Identification & Functionality

- Cleaning Ingredients Functions

Features & Benefits

- HII Features

- Advantages

- In caustic alkaline solution, iron complexing agents cause dissolution of iron oxide hydrate (flash rust).

- The temperature of the cleaning solution is only limited by the boiling point of the water.

- The effectiveness of the cleaning solution increases with temperature.

- The success of the alkaline treatment depends on the subsequent intensive rinsing with water.

- Product Highlight

- It is a specific formulation that has excellent cleaning properties in alkaline solutions up to approx. 30 °Bé (approx. 300 g/l NaOH) even when small quantities are added.

- It wets and penetrates coverings.

- Emulsifies oily and greasy components (e.g. waxes, foam oil residues.)

- Disperses fine layers of dirt.

- Re-disposition and adhesion to heating surfaces is prevented by additionally contained dispersing agents.

Applications & Uses

- Applications

- Applicable Processes

- I&I Cleaning Applications

- Applications

Application for the Aftertreatment of Pickled and Cleaned Iron Surfaces (Removal of flash rust)

- After chemical cleaning processes, usually carried out with acids, the pickled parts must be carefully rinsed and neutralized. In general the formation of initial rust cannot be avoided as the steel surfaces are highly reactive and easily oxidized after the cleaning process. This initial rust can be dissolved, however, when the neutralization process is effected with caustic soda by adding of KEBOPLEX SC.

- KEBOPLEX SC consists of a combination of specifically acting passivators, dispersants, surfactants and sequestering agents in an optimum blend. In caustic alkaline solution the iron sequestering agents cause a dissolution of the initial rust being formed after the acidification.

Cleaning Additive Application for Highly Alkaline Solutions for the Cleaning of Evaporators in Cane Sugar Mills

- To intensify and accelerate chemical cleaning operations with alkalis.

- KEBOPLEX SC is a specific formulation which has an excellent cleaning efficiency already at very low dosing rates in alkaline solutions up to 30°Bé (approx. 300 g/l NaOH).

- The detergent surfactant contained in KEBOPLEX SC wets and penetrates scales, emulsifies fatty and oily substances (e.g. waxes, residues of antifroth oils) and disperses thin films of dirt. The redeposition and adhesion to the heat surfaces are prevented by the dispersants also included in KEBOPLEX SC.

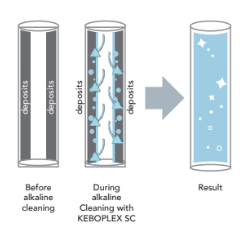

- During chemical cleaning operations in the cane sugar industry the following advantages have proved a success when adding KEBOPLEX SC:

- The dissolution of sugar decomposition products and other inconvenient organic components (e.g. waxes from the cane, proteins and other gelatinous substances) in alkaline solutions is considerably improved and accelerated.

- At the alkaline treatment with NaOH solutions of different concentration and when adding 1 - 3 % sodium carbonate (Na2CO3) calcium compounds such as calcium oxalate, calcium sulfate a.s.o. being difficult to dissolve are transformed into acid soluble compounds by adding KEBOPLEX SC. As a result the treatment period is shortened.

- At rinsings with water the detached sludge can easily be removed. Consequently the requirement of acid at a subsequent acidification is considerably reduced.

- KEBOPLEX SC is even resistant to high temperatures and effective and can be used for alkali concentrations up to approx. 30°Bé (25 %).

Blend of Sequestering Agents and Surfactants Application for the Elimination of Sugar Charcoal

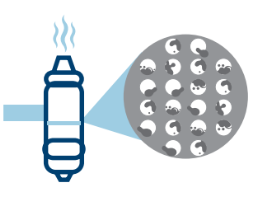

- Scales consisting of highly degraded organic substances can be formed in heat exchangers of the raw juice area, at the steam or juice side of evaporators and vacuum pans. KEBOPLEX SC is used as additive for the removal of these scales.

- KEBOPLEX SC consists of a blend of sequestering agents and surfactants which succeed in completely dissolving insoluble alkaline earth compounds and increasing the solubility of the sugar charcoal. This special blend causes a faster detachment of the scales from the metal surfaces.

- In alkaline solutions iron sequestering agents cause the dissolution of hydrated ferric oxide (initial rust).

- The temperature of the cleaning solution is limited by the boiling temperature of the water only. The efficiency of the cleaning solution increases with the temperature.

- During this alkaline process it has often been observed that the scale swells up, i.e. the volume enlarges. After the treatment it seems that the scale has not been dissolved.

- The scale often showing a greasy structure, however, dissolves at the subsequent flushing with water whereby hot water should be preferred.

- The success of the alkaline treatment depends on the following intense flushing with water. Flushing should be done until clear water runs off.

- In case of very thick scales it may be necessary to repeat the procedure.

- Areas of Application

Product for post-treatment of pickled and cleaned iron surfaces (flash rust removal) AND. Cleaning additive for highly alkaline solutions for cleaning evaporators in cane sugar factories.

- Addition and Dosing

Dosing for the Aftertreatment of Pickled and Cleaned Iron Surfaces (Removal of flash rust)

After rinsing the pickled parts should be treated with the following solution:- 1.5 % caustic soda in flakes or approx. 3.4 % caustic soda solution (45 %)

- 1.5 % - 2 % KEBOPLEX SC

Duration of Treatment

The passivation solution should circulate in the system for 2 - 3 hours at approx. 40°C to complex dissolve the existing initial rust and to form a protective film on the steel surface.

Dosing for Cleaning Additive for Highly Alkaline Solutions for the Cleaning of Evaporators in Cane Sugar Mills

- KEBOPLEX SC is added either when preparing the alkaline solution in the mixing tank or directly into the body filled with the alkaline solution ready for use.

- For the regular alkaline cleanings of the evaporators either by the spraying or when boiling out the following procedure has proved a success:

- 4 - 12 % NaOH (sodium hydroxide) by adding of

- 1.5 % KEBOPLEX SC

- After each cleaning process the losses in the NaOH concentration have to be replaced up to 4 - 12 % again. After using the solution for three times, 0.5 % KEBOPLEX SC have to be added, or according to consumption of NaOH. It is important to rinse with hot water resp. to boil out the evaporators after the alkaline treatment. Experience has shown that further scales are removed at this rinsing.

- KEBOPLEX SC can also be added to alkaline solutions with lower or higher concentrations of NaOH.

Dosing for Blend of Sequestering Agents and Surfactants for the Elimination of Sugar Charcoal

Duration of treatment and temperature should be determined by a laboratory test prior to the treatment. As basis the following may serve:

20 °C 12 - 24 hours 60 – 80 °C 6 - 8 hours - Boilers should be treated for 8 hours at least at boiling temperature.

- The following cleaning solution has been proven for years:

4 - 9 % caustic soda solution (45%) corresponding to 2 - 4 % caustic soda in flakes 2 – 4 % KEBOPLEX SC - Remove / Protect Coatings

Sugar charcoal, coatings of highly degraded organic matter.

- Working

- The non-ionic surfactants of KEBOPLEX SC do not work stoichiometrically, but wet and penetrate the deposits.

- Due to their small molecular size, they are able to penetrate and infiltrate the deposits and cause them to flake off. As a result, a very good cleaning effect is already achieved with a lower dosage.

- The additional dispersants and special surfactants can dissolve, soften, and remove organic residues, sugar carbon and organic sugar degradation products more quickly.

- They also prevent the re-accumulation of deposits formers on the evaporator surface.

Properties

- Appearance

- Yellowish, clear up to weakly turbid liquid

- Miscible in

- Water, Diluted NaOH-solution

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density (at 25°C) | approx. 1.2 | g/cm³ | — |

| pH Value (100 g/l water) | 10.5 – 11.5 | — | — |

Regulatory & Compliance

Technical Details & Test Data

- Technical Details

The product consists of a mixture of complexing agents and surfactants that dissolves insoluble alkaline earth compounds in a complex and increases the dissolution and dispersion of the sugar carbon.

- Technical Details

- Operating Temperature

Temperature should be determined in the laboratory

- 20°C, 12-24 hrs

- 60-80°C, 6-8 hrs

Packaging & Availability

- Packing

- 70 kg PE-cans

- 220 kg PE-barrels

- 1200 kg containers

Storage & Handling

- Shelf Life

- 2 Years

- Storage

In closed original packages KEBOPLEX SC is storable for at least 2 years.