Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

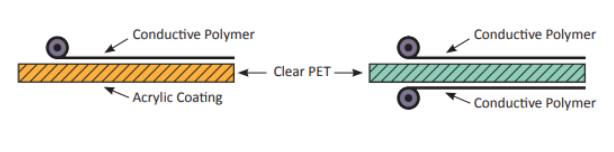

Kodak Estar Highly Conductive (HCF) Films are premium polyester (PET) films featuring a proprietary conductive coating that is applied in-line during the manufacturing process. Flexible and dimensionally stable, HCF films are extremely uniform, optically clear, highly resilient and cost effective, enabling manufacturers and product integrators to seamlessly incorporate them into a variety of electronic displays having multiple medical, automotive, consumer, military and industrial applications.

- Features

- Highest quality, optically clear, single or dual-sided PET film.

- Highly flexible, unlikely to break or lose conductivity when formed to a shape.

- Very low haze, ultra-high light transmittance.

- Customizable surface resistivity from 150–700 ohms per square.

- Invisible patterning is available on any one of the HCF films in the category.

- Can be also used to effectively provide full-sheet conductivity.

- Can be coated on one or both sides in 127–178 μm (5–7 mil) thickness, up to 1,384mm width, and unlimited length.

- Cost-effective alternative to ITO.

- For additional customizable thicknesses, widths and lengths, talk to us!

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Applications

Kodak Estar HCF Films are integrated into multiple display and touch function applications where either resistive or capacitive technologies are used.

Projected Capacitive (ProCap)

- Touch Displays

- Smart Watches

- Automotive and Aerospace Displays

- Consumer Appliances

- Biosensors

- Medical Devices

Full Sheet Conductors

- LCD Electrode Layers

- Thermo Heating Devices

- Smart Window Conductive Layers

Resistive Applications

- Point of Sales Devices

- Resistive Displays

- Kiosk Displays

- Membrane Switches

Properties

- Color

- Physical Form

- Typical Properties

- Physical Attributes

Roll Integrity

- The edge of the roll is free of nicks, cuts or visible telescoping greater than ± 6.3 mm (0.25 inches).

- The roll contains no gage bands which visibly distort the film surface.

Consistent Surface Quality

- Material is free from any surface imperfections, the result of an exclusve Kodak in-line scanning process which detects, corrects, and ultimately delivers a product that meets or exceeds specifications.

- Kodak quality technicians evaluate sample product quality using internal and external standards to confirm that all applicable quality standards are met.

| Value | Units | Test Method / Conditions | |

| Surface Resistivity | 385.0 | ohms/square | 4 point probe |

| PEDOT/PSS Coating Thickness | max. 0.20 | micron | Calculated Nominal Thickness |

| Haze (Single Side) | max. 1 | % | ASTM D 1003 |

| Haze (Dual Side) | max. 1 | % | ASTM D 1003 |

| Visible Light Transmittance (Single Side) | min. 90 | % | ASTM D 1003 |

| Visible Light Transmittance (Dual Side) | min. 87 | % | ASTM D 1003 |

| Thermal Change (Average Machine Direction, 30 minutes at 150°C) | max. 1 | % | — |

| Acetone (Change in resistivity when exposed to, 10 minutes at 24°C) | max. 10 | % | Kodak Method |

| IPA (Change in resistivity when exposed to, 10 minutes at 24°C) | max. 5 | % | Kodak Method |

| Methanol (Change in resistivity when exposed to, 10 minutes at 24°C) | max. 12 | % | Kodak Method |

| Toluene (Change in resistivity when exposed to, 10 minutes at 24°C) | max. 4 | % | Kodak Method |

| Water (Change in resistivity when exposed to, 10 minutes at 24°C) | max. 8 | % | Kodak Method |

Technical Details & Test Data

- Technical Details

Adhesion

Dry tape adhesion, no removal

Wet adhesion rating of good

Environmental Testing 60°C, 90% RH, 240 hours, max. 12% SER change

Etching Material can be laser and chemically etched to create a pattern.

- Test Data

Packaging & Availability

- Packaging for a Perfect Product

- Standard core, fiber board or plastic core; inside diameter 152 mm ± 3 mm (6 inches ± 0.04 inch).

- Each roll is suitably wrapped to seal the product.

- Each roll is horizontal, supported on core ends.

- Each container is labeled with product and roll identification.

- Sizes Available

Thickness (Micron) Width (mm, 1/2” knurl) Length (m) 127 1384 914