Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

Kodak Estar Heat Stabilized (HS) Films are a premium polyester (PET) produced to maintain consistent dimensional stability (<0.2%) at temperatures of 150°C -30 minutes (ASTM D.1204). Kodak Estar HS films are manufactured with minimal surface contact, and our inline heat stabilization process results in a high quality, dimensionally stable, exceptionally uniform, flexible, optically clear and cost-effective material. Films can be coated on one or both sides in 76 μm, 102 μm, 127 μm and 178 μm thicknesses.

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Applications

Estar HS films are used for many touch function flexible printed electronics applications. Examples:

- Consumer appliances

- Membrane touch switches

- Automotive seat sensors

- Electro-luminescent surfaces/lamps

- RFID tags/labels

- Photovoltaics

- Diagnostic test strips

- Transfer release films

- High heat laser printing

Properties

- Physical Form

- Physical Properties

- Mechanical Properties

- Thermal Properties

- Optical Properties

- Physical Attributes

Optical-grade Surface Quality

- A cushion of air transports the film throughout the stretching process. Films are then scanned to meet the stringent requirements for high optics applications.

- Less than one micron thick adhesion primer. Films can be coated with an adhesion-promoting primer and winding aid.

- Minimum shrinkage in both the machine direction (MD) < 0.1% and transverse direction (TD) < 0.2%.

- Range of thicknesses 76 μm, 102 μm, 127 μm and 178 μm.

- Greater than 90% transmittance with less than 1% haze.

Optima Roll Intergrity

- The edge of the roll is free of nicks, cuts or visible telescoping greater than ± 6.3 mm (0.25 inches).

- The roll contains no gage bands to visibly distort the film surface.

Consistent Product Quality

- Kodak inspects material during the manufacturing process using in-line scanners to detect, correct, and deliver material that meets or exceeds specifications.

- Kodak quality technicians consistently evaluate sample product quality using internal and external standards to confirm quality standards are met.

| Value | Units | Test Method / Conditions | |

| Width Tolerance | ± 3 | mm | Kodak Inline Scanner |

| Length Tolerance | ± 30 | m | Kodak Inline Scanner |

| Knurls (Each side) | 12.5 | mm wide | — |

| Planarity (Max "flute", 10 ft sample) | max. 0.5 | mm | Kodak Planarity Method |

| Value | Units | Test Method / Conditions | |

| Tensile Strength | min. 25,000 | psi | ASTM D 882 |

| Break Elongation | min. 70 | % | ASTM D 882 |

| Young’s Modulus | min. 500,000 | psi | ASTM D 882 |

| Value | Units | Test Method / Conditions | |

| Shrinkage MD (30 min at 150°C) | 0.16 | % | Kodak Method |

| Shrinkage TD (30 min at 150°C) | 1.0 | % | Kodak Method |

| Value | Units | Test Method / Conditions | |

| VLT (With primer) | min. 90 | % | ASTM D 1003 |

| Haze (With Primer) | max. 1.5 | % | ASTM D 1003 |

Regulatory & Compliance

- Certifications & Compliance

- Certifications

- UL 94 VTM-2 - for 102 μm, 127 μm, 178 μm¹

- ISO 9001

Technical Details & Test Data

- Test Data

Kodak Estar HS Films 201/202

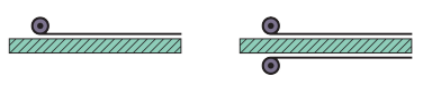

Coated with an acrylic tenaciously aggressive adhesion-promoting primer and winding aid. 201 Film is coated on one-side 202 Film is coated on both sides.

Kodak Estar HS Films 301/302

Coated with a PVDC adhesion-promoting primer and winding aid. 301 Film is coated on one-side 302 Film is coated on both sides.

Packaging & Availability

- Packaging Type

- Packaging for a Perfect Product

- Standard core; inside diameter 152mm ± 3mm (6 inches ± 0.04 inch).

- Each roll is suitably wrapped to seal the product.

- Each roll is horizontal, supported on core ends.

- Each container is labeled with product and roll identification.