Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Highlights

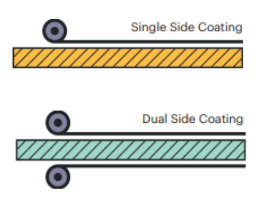

KODAK ESTAR Polyester (PET) films offer very high clarity, optical-grade surface quality for use in a variety of industrial applications. These films can be processed uncoated or with coatings on one or both sides of the material — up to three coatings per side. Coating options can include:

- Adhesion promoting primers

- Anti-static coatings

- Gels

- Adhesion coatings for aqueous or solvent based inks.

- Features

- Optical-grade surface quality — products are manufactured with minimal surface contact, then scanned to meet the stringent requirements for optical applications.

- Greater than 90% transmittance with less than 1% haze.

- Available in an array of widths and thicknesses.

- Throughout the stretching process, films are transported on a cushion of air without roller contact to virtually eliminate micro scratches that can compromise quality.

- Kodak’s Six Sigma Black Belt quality strategy includes statistical modeling and design, rigorous change management, and unsurpassed manufacturing process control.

- Films are available bare or can be coated on one or both sides with a variety of adhesives, gels, inks or anti-stats.

- Available in thicknesses as low as 2.5 mil (63.5 µm) and as thick as 7.5 mil (188 µm) up to a maximum width of 1384 mm (54.5 inches).

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Applications

Highly flexible and dimensionally stable, KODAK ESTAR PET films are extremely uniform, very resilient and cost effective, enabling manufacturers and product integrators to use them for multiple industrial purposes, among them:

- Labels and printing

- Metallization

- Emulsion-based coating systems

- Flexible electronic displays

- Membrane touch switches

- Vacuum molded products and packaging

Properties

- Physical Form

- Physical Properties

- Mechanical Properties

- Thermal Properties

- Optical Properties

- Physical Attributes

Roll Intergrity

- The edge of the roll will be free of nicks, cuts or visible telescoping greater than ± 6.3 mm (0.25 inches).

- The roll will not contain gage bands which will visibly distort the film surface.

- There are no splices or cutouts in the roll.

Product Quality

- Kodak inspects material during the manufacturing process using in-line scanners to detect, correct, and deliver material that meets or exceeds specifications.

- Kodak quality technicians consistently evaluate sample product quality using internal and external standards to confirm quality standards are met.

| Value | Units | Test Method / Conditions | |

| Width Tolerance | ± 3 | mm | Kodak Inline Scanner |

| Length Tolerance | ± 30 | m | Kodak Inline Scanner |

| Knurls (Each side) | 12.5 | mm wide | — |

| Planarity (Max "flute", 10 ft sample) | max. 0.5 | mm | Kodak Planarity Method |

| Value | Units | Test Method / Conditions | |

| Tensile Strength | min. 25,000 | psi | ASTM D 882 |

| Break Elongation | min. 70 | % | ASTM D 882 |

| Young’s Modulus | min. 500,000 | psi | ASTM D 882 |

| Value | Units | Test Method / Conditions | |

| Shrinkage MD (30 min at 150°C) | 1.0 | % | Kodak Method |

| Shrinkage TD (30 min at 150°C) | 1.0 | % | Kodak Method |

| Value | Units | Test Method / Conditions | |

| VLT (With primer) | min. 90 | % | ASTM D 1003 |

| Haze (With Primer) | max. 1.5 | % | ASTM D 1003 |

Regulatory & Compliance

- Certifications & Compliance

- Certifications

- Kodak ESTAR Polyester Films; 5481 Film/ESTAR base UL 94 VTM-2 — for 127 µm, 178 µm¹. All Kodak ESTAR Polyester Films are manufactured with 5481 Film/ESTAR base and may then have coatings applied.

- Kodak ESTAR’s quality system is ISO 9001:2015 Certified.

Technical Details & Test Data

- Test Data

Packaging & Availability

- Packaging Type

- Packaging

- Standard core; inside diameter 152mm ± 3mm (6 inches ± 0.04 inch).

- Each roll is suitably wrapped to seal the product.

- Each roll is horizontal, supported on core ends.

- Each container is labeled with product and roll identification.

- Availability

Kodak Estar PET Films are available in 2.5, 3, 4, 5 and 7 mil thicknesses. Films are provided on master rolls between 50 inches (1,270 mil) and 56 inches (1,422 mil) wide with Knurls on each side. Lengths vary from 6,000 feet (1,829 meters) to 10,000 feet (3048 meters) depending on coatings used and the thickness of the product. KODAK ESTAR PET Films can be processed uncoated or with coatings on one or both sides of the material — up to three coatings per side. For specific dimension or for dimensions tailored to your precise specifications talk to us!