Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Reinforcement Material

- Composite Materials Functions

- Chemical Structure

- Epoxy

- Technologies

- Weaving Style

Plain, twill, UD

Features & Benefits

- Materials Features

- Key Features

- Suitable for fast press molding,

- Cosmetic grade visual carbon look,

- Class A Surface quality,

- Good hot de-molding performance

- Suitable for structural applications

- Good chemical resistance

- Suitable for Cataphoresis/ Hot Painting/Hot adhesive bonding

- Suitable for autoclave short curing cycle

Applications & Uses

- Applications

- Composites End Use

- Plastics & Elastomers End Uses

- Composites Processing Methods

- Applications

Visual composites, Automotive

Properties

- Typical Properties

- Cured Matrix Properties

Cured Matrix Properties (cured at 80 ⁰C 30 minutes - 100 ⁰C 30 minutes - 140 ⁰C 60 minutes) Glass Transition Temp

(Tg by DSC) [°C]Ramped from RT to 150°C (10C/min) @150 °C 5 min

Ramped 150 to 210°C (10C/min)155 Isothermal press at160 °C , mold at RT

Wait to mold reach 160 °C at160 °C 5 min

Ramped 160 to 210°C (10C/min)160 Isothermal press at180 °C , mold at RT Wait to mold reach 180 °C at 180 °C 5 min

Ramped 180 to 210°C (10C/min) at 210 °C 30 min Postcure165 ISO 11357 (RT to 210°C, at 210°C 5 mins, cool to 100°C) 145 Tg DMA 1Hz, 3°C/min Onset of E’ 156 Maximum of Tanδ 198 Maximum of E’’ 173

| Value | Units | Test Method / Conditions | |

| Mid Tg (150 - 180°C) | 150 | — | — |

| Initial Mix Viscosity (65°C) | 35 | Pas | — |

| Gel Time (Hot Plate)( 140°C) | 70 | Sec | — |

| Gel Time (Hot Plate)( 150°C) | 40 | Sec | — |

| Gel Time (Hot Plate)( 160°C) | 15 | Sec | — |

| Gel Time (Rheometer)(120°C) | 260 | Sec | — |

| Gel Time (Rheometer)(140°C) | 69 | Sec | — |

| Gel Time (Rheometer)(150°C) | 54 | Sec | — |

| Gel Time (Rheometer)(160°C) | 38 | Sec | — |

| Gel Time (Rheometer)(180°C) | 17 | Sec | — |

| Tensile Strength | 39 | MPa | Tensile Test (ASTM D3039) |

| Tensile Modulus | 3028 | MPa | Tensile Test (ASTM D3039) |

| Elongation at maximum | 1,5 | % | Tensile Test (ASTM D3039) |

| Elongation at maximum | 5 | % | Flexural Test (ASTM D790) |

| Compression Strength | 107 | MPa | Compression Test (ASTM D3410) |

| Compression Strain at maximum | 4.6 | % | Compression Test (ASTM D3410) |

| Flexural Strength | 136 | MPa | Flexural Test (ASTM D790) |

| Flexural Modulus | 3490 | MPa | Flexural Test (ASTM D790) |

| Fracture toughness K1C (Bend Notch Test, 5 min 140°C) | 1.05 | MPa√m | — |

| Fracture energy G1C (Bend Notch Test, 5 min 140°C) | 340 | J/m2 | — |

| Maximum Displacement | 160 | °C | HDT (TMA) |

| Dry Fabric Areal Weight | 200 - 600 | gsm | — |

| %Resin Content (by weight) | 37 - 48 ± 2 | — | — |

| Tackiness Level | Low Tack | — | — |

Technical Details & Test Data

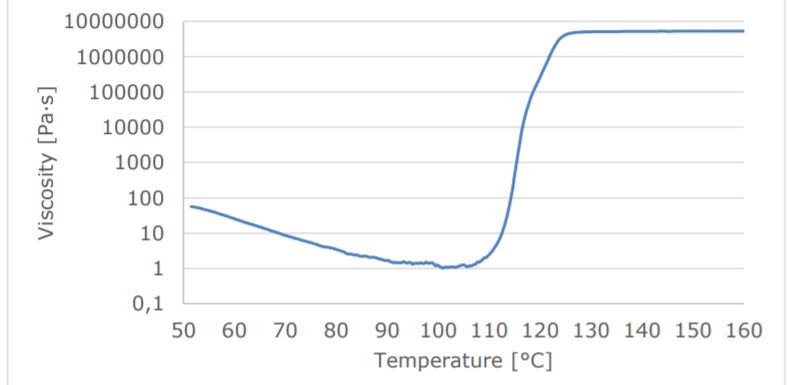

- Dynamical Viscosity Profile of the Formulation

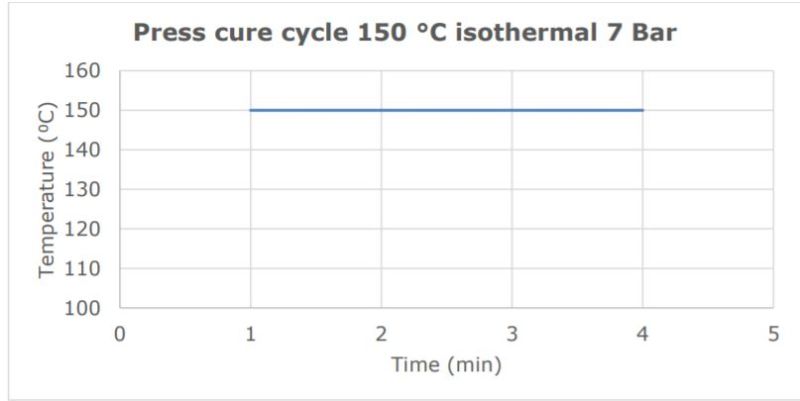

- Compression Molding (Recommended)

Pressure: Minimum of 7 bar (7.2 kg/cm2) (*), 30 bar is recommended.

Pressure: Minimum of 7 bar (7.2 kg/cm2) (*), 30 bar is recommended.Ramp Rate: Consolidated prepregs (preforms) can be loaded into a pre-heated tool (compression molding).

Recommended Cure Cycle: 3 minutes at 150 C +/-5C, 30 bar @ Press

Cool Down: Cured parts can be removed from tool without cooling (hot demolding). Recommended Post-Cure Cycle(if needed): 6 hours at 150 C +/-5C @ Oven

Storage & Handling

- Storage Life

6 months at -18°C

- Work Life

2 weeks at RT

- Prepreg Shelf Life

Prepreg Shelf Life at 23 °C for 2 weeks

- Tack Life

5 Days at RT Initial