Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Technical Characteristics

- Epojet is a two-component solvent-free epoxy adhesive. The pre-measured components (component A = resin and component B = hardener) must be mixed together before being used.

- Once mixed, Epojet becomes a liquid with low viscosity very suitable for injection.

- Epojet polymerizes without shrinkage and once hardened is waterproof.

- Epojet has very good insulating properties and high mechanical strength; furthermore it adheres perfectly to concrete and steel.

Applications & Uses

- Applications

- Application Method

- Adhesive & Sealant Type

- Where to Use

- Monolithic repair of structures with cracks or fissures caused by heavy loads, accidental impacts and earthquakes.

- Bonding and reinforcement of structures by low pressure injection.

- Precise anchoring of metallic structures.

- Some Application Examples

- Structural repairs of beams, pillars and fissured floors by low pressure injection.

- Reinforcement of beams and floors by using injection and béton plaqué, the plated concrete technique, when the plates to be bonded are fitted with lateral flaps and it is therefore impossible to apply Adesilex PG1 or Adesilex PG2 directly.

- Restoring and waterproofing cracks in reservoirs, tanks and canals.

- Restoring, by injection, various elements of façades, cladding and architectural elements that are loose.

- Protective injections of post-compression cable ducts.

- Structural consolidation and restoration of civil and industrial road constructions which show signs of cracking.

- Sealing of fissures in cementitious screeds.

- Consolidation and restoration, by injection, of concrete structures damaged by earthquakes, settlement or impact.

- Anchoring metallic structural work and steel reinforcement.

- Recommendations

- Do not use Epojet at temperatures below +5°C.

- Do not apply Epojet to wet surfaces.

- Do not apply Epojet on dusty, friable or weak substrates.

- Do not use Epojet for sealing expansion joints

- Application Procedure

Prepation the substrate

Before injecting Epojet, the concrete substrate must be perfectly sound and clean. Remove all crumbly and loose parts, dust, cement laitance and paint by sanding or brushing. Concrete soaked with oil or grease must be completely demolished.

Placing the steel reinforcement and injection

Remove all traces of rust or grease by sandblasting down to bright metal (SA 2½) or, if necessary, with emery paper and de-grease with solvents. Once these preparatory procedures have been completed, fix the steel plates to the concrete with expanding bolts and then seal the injectors with Adesilex PG1 or Adesilex PG2.

Sealing cracks by injection

- Make a series of holes of 8-9 mm in diameter along the sides of the cracks and orient the injectors to intercept the cracks. Blow out the cavities with compressed air to remove all the dust formed during the drilling. Insert the appropriate injection tubes into the holes and seal with Adesilex PG1 or Adesilex PG2.

- If it is not possible to drill holes because the cracks are so small and widespread throughout the concrete, use injectors with a flat end plate and fasten them to the concrete over the cracks with expansion plugs, or with Adesilex PG1 or Adesilex PG2. Wait until the Adesilex PG1 or Adesilex PG2 has set (at least 12 hours) and then inject compressed air to make sure the system is completely free.

Preparing the product

First the two components of Epojet must be mixed together. Pour component B into component A and manually mix with a trowel (for small amounts), or with a low speed heavy duty drill (for large quantities) avoiding the formation of air bubbles and until the mix is perfectly homogeneous. Do not use partial quantities of the parts to avoid measuring errors that could lead to the incomplete hardening of Epojet. If the packs need to be used partially, use an electronic precision scale.

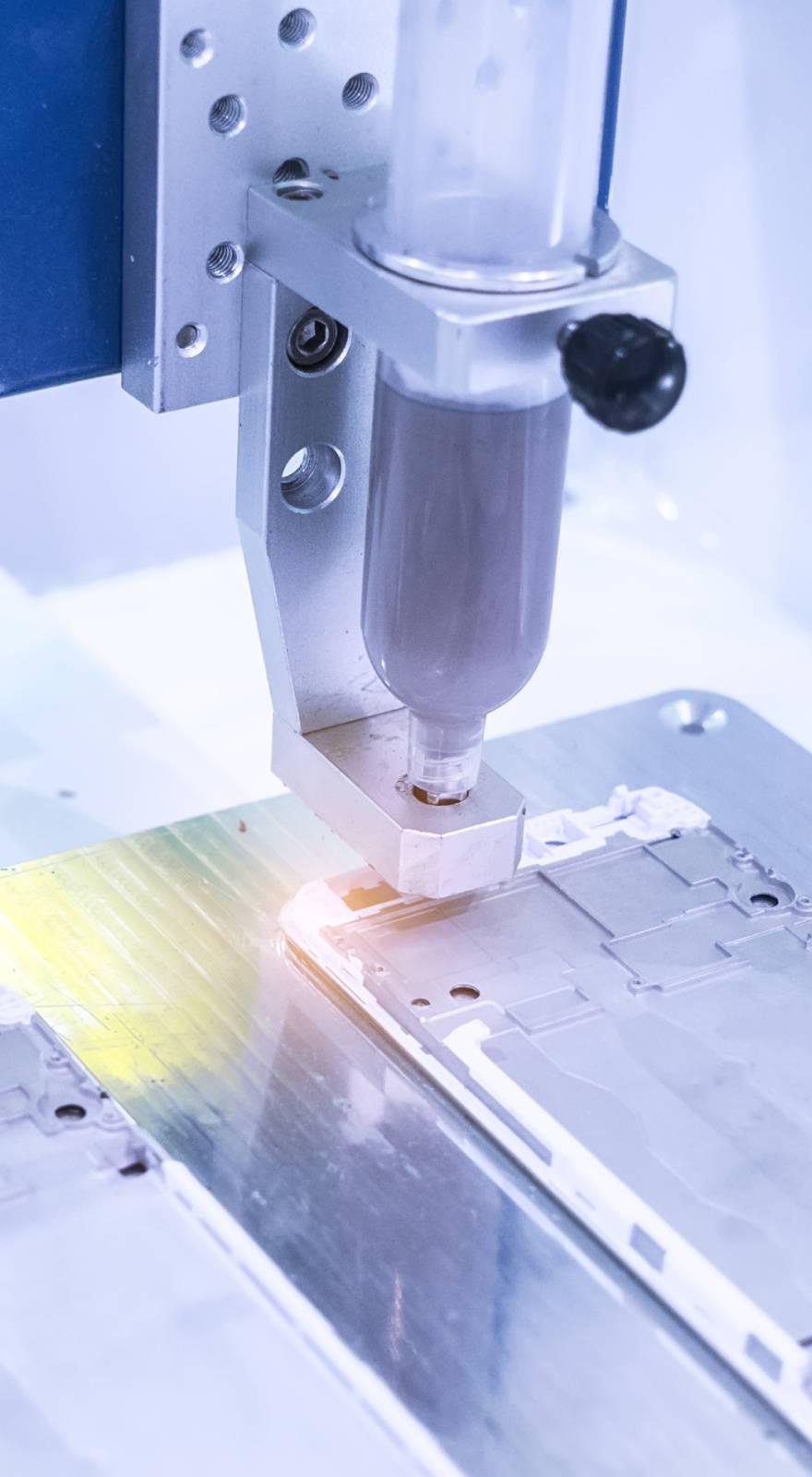

Applying the product

- Begin immediately from the lowest tube and start injecting Epojet until the resin overflows out of the next tube. Close the tube used for injection and inject Epojet in the next one positioned just above until the fissure is completely sealed.

- Horizontal fissures can be sealed simply by pouring Epojet directly into the crack. Epojet must be used within 40 minutes from its preparation and at +23°C. Avoid using Epojet when the outdoor temperature and that of the substrate is less than +5°C.

Cleaning

Tools used for preparing and injecting Epojet must be cleaned immediately after use and before it hardens with solvents (ethyl alcohol, toluene, etc.).

- Consumption

Sealing cracks 1.1 kg/l of cavity to be filled. Bonding concrete to steel 1.1 kg/m² per mm of thickness

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.15 | g/cm3 | — |

| Consistency | Liquid | — | — |

| Brookfield Viscosity (rotor 2 - 20 revs) | 500.0 | mPa•s | — |

| Consistency of Mix (at +23°C and 50% R.H.) | fluid liquid | — | — |

| Color of Mix (at +23°C and 50% R.H.) | Transparent yellow | — | — |

| Density of Mix (at +23°C and 50% R.H.) | 1.14 | kg/l | — |

| Brookfield Viscocity (at +23°C and 50% R.H. (rotor F - 5 revs)) | 380.0 | Pa.s | — |

| Workability Time (at +23°C) | 40.0 | minutes | EN ISO 9514 |

| Workability Time (at +30°C) | 20.0 | minutes | EN ISO 9514 |

| Setting Time (at +23°C) | 4.0 | hours | — |

| Setting Time (at +30°C) | 3.0 | hours | — |

| Application Temperature (at +23°C and 50% R.H.) | 5 - 30 | °C | — |

| Complete Hardening Time (at +23°C and 50% R.H.) | 7 days | — | — |

| Tensile Adhesion Force | Cohesive failure of the substrate | — | EN 12618-2 |

| Inclined Shear Adhesion Strength | Monolithic failure | — | EN 12618-3 |

| Volumetric Shrinkage | 1.9 | % | EN 12617-2 |

| Glass Transition Temperature | min. 45 | °C | EN 12614 |

| Sand Column Injectability (Dry State, injectability class) | 281.0 | seconds | — |

| Sand Column Injectability (Damp State, injectability class) | 281.0 | seconds | — |

| Sand Column Injectability (Dry State, indirect traction) | 14.0 | N/mm2 | EN 1771 |

| Sand Column Injectability (Damp State, indirect traction) | 11.0 | N/mm2 | EN 1771 |

| Durability (Freeze/Thaw and Wet/Dry Cycles) | Cohesive failure of the substrate | — | EN 12618-2 |

| Development of Tensile Strength (+5°C) | min. 4.9 | N/mm2 | EN 1543 |

| Creep (Movement with a load of 50 Kn for 3 Months) | 0.46 | mm | EN 1544 |

| Slip-Resistance of Steel Reinforcement Rods (Movement with a load of 75 KN) | 0.58 | mm | EN 1881 |

| Compressive Strength (after 7days) | 95.0 | N/mm2 | EN 12190 |

| Tensile Strength | 44.0 | N/mm2 | EN ISO 527 |

| Tensile Modulus of Elasticity | 3400.0 | N/mm2 | EN ISO 527 |

| Deformation at Failure | 1.0 | % | EN ISO 527 |

| Reaction to Fire | E | — | EN 13501-1 |

Safety & Health

- Safety Instructions for the Preparation and Application

- Epojet component A is irritant for the skin and the eyes, Epojet component B is corrosive and can cause burns. Furthermore, it is harmful when inhaled or swallowed. Both component A and component B can cause sensitisation if they come in contact with the skin of those predisposed. The product contains low molecular weight epoxy resins that may cause sensitisation if cross-contamination occurs with other epoxy compounds.

- During use, wear protective gloves and goggles and take the usual precautions for handling chemicals. In case of contact with the eyes or the skin, wash immediately with plenty of water and seek medical attention. Use a suitable device for the protection of the respiratory tract.

- When the material reacts it generates a high amount of heat. We recommend applying the product as soon as possible after mixing components A and B and to never leave the container unattended until it is completely empty.

- Epojet component A and component B are dangerous for aquatic life, do not dispose of them in the environment.

Packaging & Availability

- Packaging Type

- Packaging

- 4 kg kits (component A : 3.2 kg - component B : 0.8 kg)

- 2.5 kg kits (component A : 2 kg - component B : 0.5 kg).

Storage & Handling

- Storage

24 months if stored in its original packaging. Keep the product stored in an area with a temperature not below +5°C.