Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Technical Characteristics

- Foamjet T is a two-component polyurethane, halogene free resin, having very high reactivity and excellent mechanical performance and chemical stability.

- After having mixed the two components together in the ratio 1:1 by volume, with a special pump equipped by static helicoidal mixer, Foamjet T forms a polyurethane foam of great strength.

- Due to its rheological properties, Foamjet T can also penetrate through small cracks and sealing them even if they are subject to water infiltrations.

- At the end of the setting time, within a few seconds, depending on the temperature, Foamjet T becomes completely waterproof and ensures an adequate consolidation to the treated structure.

- Foaming/hardening reaction takes a very few seconds but, either upon peculiar requirements or in presence of low application temperatures (lower than +15°C), it is possible to reduce reaction time by adding, into the Foamjet T part A, a small quantity (0.5-2.5% by weight) of a proper catalyst Foamjet AKS.

Applications & Uses

- Applications

- Compatible Substrates & Surfaces

- Adhesive & Sealant Type

- Where to Use

- Waterproofing rock or loose ground diggings, dams, shafts or tunnels where there is strong water ingress.

- Waterproofing diaphragm and pile walls even when subject to constant contact with water.

- Some Application Examples

- Waterproofing tunnels subject to water ingress through possible cracks or in fissures between keystones.

- Waterproofing shafts or hydraulic structures that manifest water leakage through working joints or cracks.

- Repairing cracks in dams, channels and bulkheads when permanently immersed in water.

- Sealing cracks in floorings or slabs that are damp or saturated with water.

- Recommendations

Foamjet T is particularly recommended for waterproofing large areas where there is water ingress, also under pressure. Foamjet T part A might be affected by a significant viscosity increase, when stored at low temperature.

Temperature influences the hardening time of Foamjet T; temperatures lower than +15°C lengthen setting time. It is therefore recommended to seek information from our technical service before injection takes place in structures that are subject to high pressure water ingress.

- Directions for Use

Positioning the injectors

Make off-set holes on the sides of the cracks. The size of the holes should fit the diameter of the injectors that will be used. Expansion injectors with a non-return valve can be easily fixed by self-tapping completely to the walls of the hole. If there is no water ingress, normal copper, steel or PVC tubes with a diameter of approximately 10 mm can be used.

Preparing and injecting the product

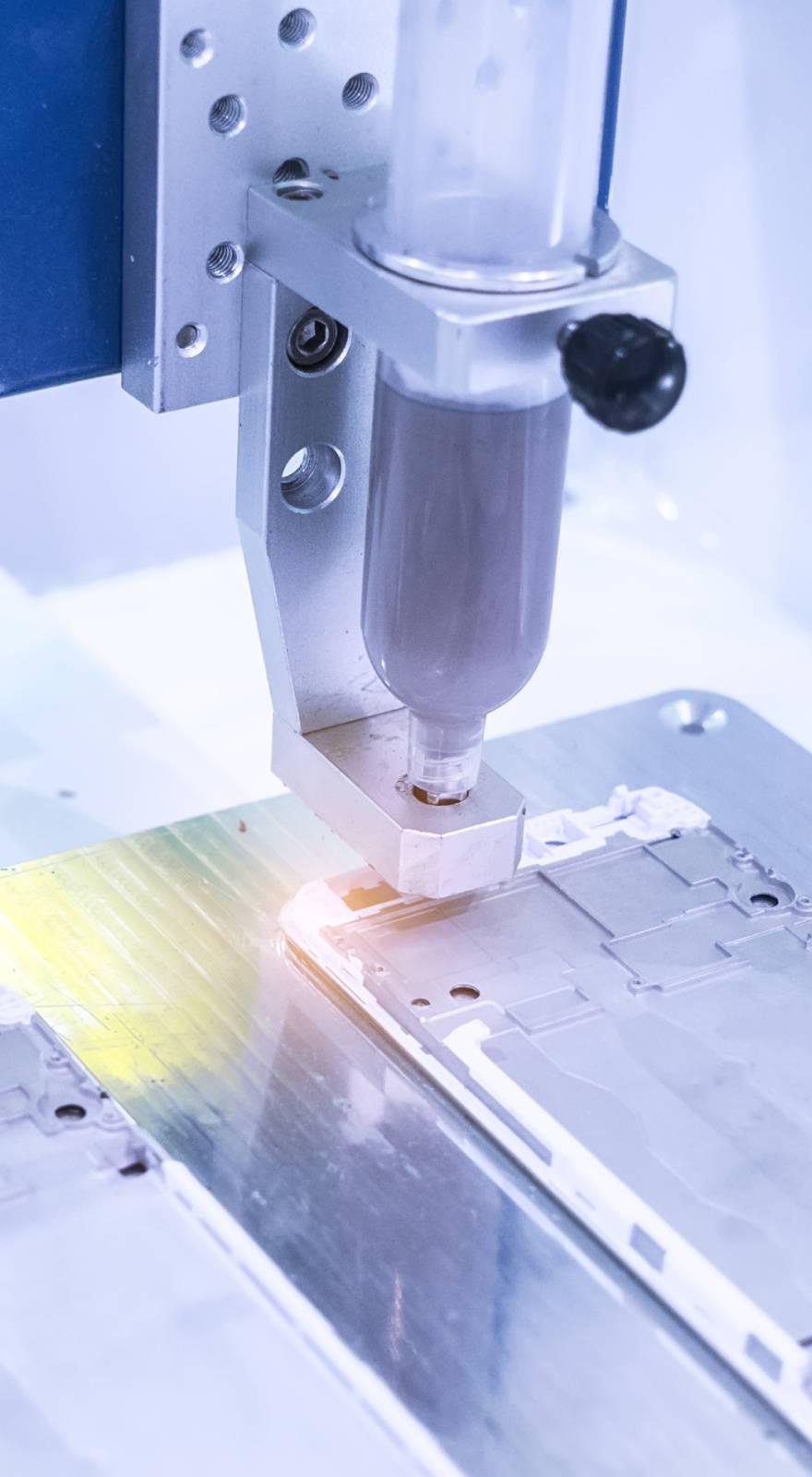

The two components that make up Foamjet T must be mixed together by a special pump for two-component resins.

In order to carry out injection, Foamjet T part A and Foamjet T part B in the ratio 1:1 by volume, must be separately conveyed through the pump and into the nozzle previously placed on the injector and mixed by a helicoidal mixer placed within the nozzle.

After mixing, Foamjet T must be injected continuously through the crack. When the two components are mixed, the viscosity of the mixture increases substantially, therefore the injected mixture will not separate or be washed out by the water pressure. The increase in volume of the foam and its fast reaction stops the water ingress within a few minutes. In the absence of water, Foamjet T hardens without increasing in volume and rapidly seals the crack.

Cleaning

Clean injection equipment (pump and tubes) with mineral oil free of water and impurities after use.

- Consumption

If the reaction takes place in free expansion, 1 liter of product produces 20 liters of foam. If the reaction is affected in a confined space, consumption depends on the degree of confinement.

Properties

- Physical Form

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density (+23°C) | 1.034± 0,026 | g/ml | EN 2811-1 |

| Consistency | Liquid | — | — |

| Viscosity (rotor 2 - 20 revs) | 471 ± 94 | mPa•s | UNI EN 3219 |

| Foaming Ratio | 3 - 10 | — | — |

| Reaction Start | 10.0 | minutes | — |

| Reaction End | 3.0-3.30 | hours | — |

| Temperature | 25.0 | °C | — |

| Water Content | 10.0 | g | — |

Packaging & Availability

- Packaging Type

- Packaging

- 5 kg kit (component A = 4 kg - component B = 1 kg)

- 2.5 kg kit (component A = 2 kg - component B = 0.5 kg).

Storage & Handling

- Storage

Foamjet T can be stored for maximum 1 year in a covered and dry place in its original sealed containers and at temperatures between +5°C and +30°C.