Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Fillers Included

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- Plastic Part Replacement

- Housings

- Sensor Mounts

- Cosmetic Prototypes

Properties

- Flame Rating

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Modulus | 2.4 | GPa | D638 |

| Tensile Stress at Yield | 40 | MPa | D638 |

| Tensile Stress at Break | 37 | MPa | D638 |

| Tensile Strain at Break | 25 | % | D638 |

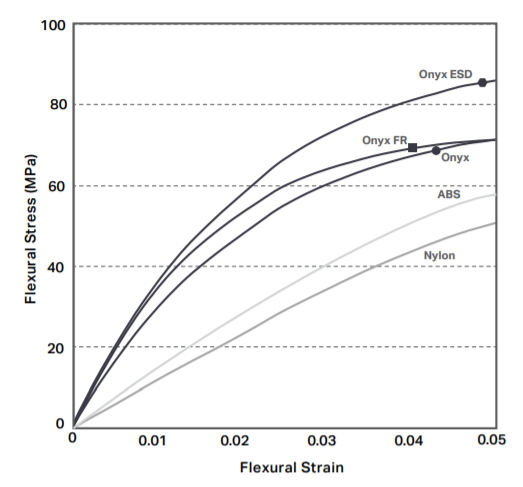

| Flexural Strength | 71 | MPa | D7901 |

| Flexural Modulus | 3 | GPa | D7901 |

| Heat Deflection Temp | 145 | °C | D648 B |

| Izod Impact - notched | 330 | J/m | D256-10 A |

| Density | 1.2 | g/cm³ | — |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Composite Base

Markforged Composite Base materials print like conventional FFF thermoplastics. They can be printed by themselves, or reinforced with any of our continuous fibers, including Carbon Fiber, Kevlar, and Fiberglass.

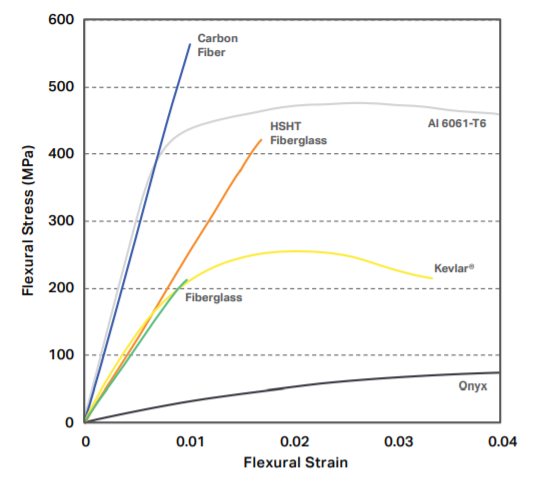

- Continuous Fiber

Continuous Fibers are laid down on the inside of parts through a second fiber nozzle. They cannot be printed by themselves - instead, they are used to reinforce parts printed out of a composite base material like Onyx.