Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

- Product Highlights

- Very economical way to remove heavy soils and light rust

- Low foaming at ambient temperatures, and even lower when used above 120°F (49°C)

- Can be recycled using XYBEX equipment

- Contains no solvents, borates, silicates, nitrites, or amines

- Long bath life

- Excellent compatibility with magnesium

- Will prevent flash rusting and provide one to-two days of in-process corrosion inhibition if not rinsed

- A manufacturer of joint replacement systems and medical tools had a multi-step process to clean parts utilizing spray washing, dunk tank immersion cleaning, and a final two part ultrasonic cleaning. A project to reduce cost without sacrificing cleanliness was initiated by Master Fluid Solutions. Through extensive tests on cleaners and processes, Master Fluid Solutions found the customer could eliminate one cleaning process, use less cleaner itself, and consume less energy through the use of Master STAGES CLEAN 2017 for a combined savings of 44% per year in cleaner material and process energy costs.

- Additional Information

- Industrial Use Only

- Consult Master Fluid Solutions before using on any metals or applications not specifically recommended.

- This product should not be mixed with other metalworking fluids or metalworking fluid additives, except as recommended by Master Fluid Solutions, as this may reduce overall performance, result in adverse health effects, or damage the machine tool and parts. If contamination occurs, please contact Master Fluid Solutions for recommended action.

- Master STAGES™ is a trademark of Master Chemical Corporation d/b/a Master Fluid Solutions.

Applications & Uses

- Markets

- Applications

- Application Area

- Application Method

- Compatible Substrates & Surfaces

- Use Level

- 1.0 - 7.0 %

- Application Guidelines

- CLEAN 2017 is normally used at concentrations from 1%-7%. We recommend 3% as a starting concentration to provide reserve surfactant.

- This product is suitable only for steel, stainless steel, cast iron, titanium, pure copper, and magnesium parts. Do not use on aluminum alloy, copper alloy, or zinc.

- Operating temperature should be between 70°F to 210°F (21°C to 99°C) for spray cleaning.

- CLEAN 2017 will work well in immersion washers as well as ultrasonic baths under 120°F (49°C).

- High pH cleaners such as CLEAN 2017 often produce "soaps" as part of their cleaning action. CLEAN B1 is effective at reducing foam resulting from the formation of these soaps and may be used in conjunction with CLEAN 2017.

- Product Applications

Applications : Corrosion inhibition, parts washing.

Soils : Coolant residues, greases, oils, sulfurized oils, and waxes.

Metals : Cast iron, copper, magnesium, stainless steels, steels, and titanium.

Industries : Automotive, bearing, firearms, general engineering, general fabrication, general industry, job shop, machine tool, medical, and tool.- Mixing Instructions

- Recommended usage concentration in water: 1.0% - 7.0%.

- To help ensure the best possible working solution, add the required amount of concentrate to the required amount of water (never the reverse) and stir until uniformly mixed.

- Recommended Metalworking Concentrations

Design concentration range : 1.0% - 7.0%

Properties

- Physical Form

- Odor

- Mild, detergent (Concentrate)

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Flash Point (Concentrate) | max. 212 | °F | ASTM D92-90 |

| pH (Concentrate as Range) | 13.5 - 14.0 | — | — |

| pH (Typical Operating as Range) | 12.5 - 13.0 | — | — |

| V.O.C. Content | 0.0 | g/l | ASTM E1868-10 |

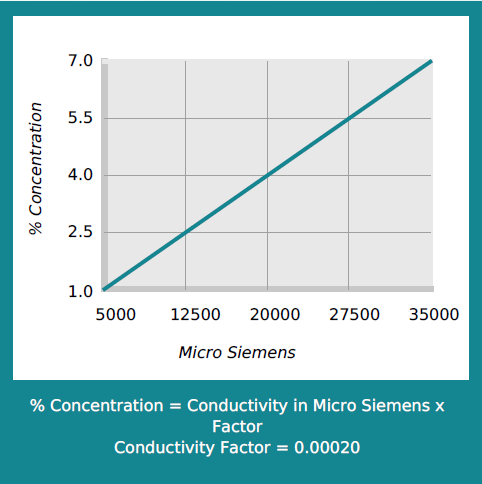

| Cleaner Conductivity Factor | 0.0002 | — | — |

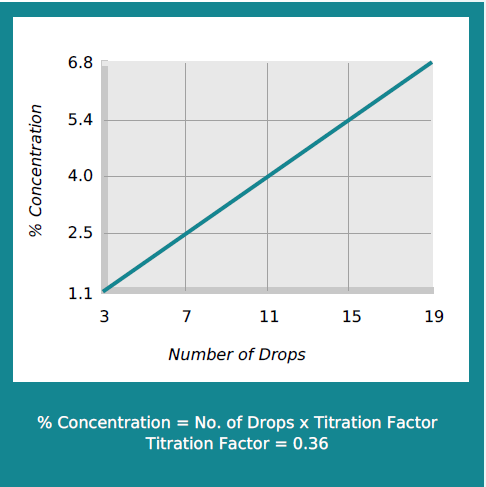

| Titration Factor | 0.36 | — | CL-1 Titration Kit |

| Number of Cleaner Vials | 1.0 | — | CL-1 Titration Kit |

| Cleaner Indicator A or B | A | — | CL-1 Titration Kit |

Regulatory & Compliance

- Product Compliance

CLEAN 2017 is free of amines, borates, nitrites, silicates, and solvents.

Technical Details & Test Data

- Test Data

Concentration by Conductivity

Concentration by Titration

Packaging & Availability

- Packaging Type

- Packaging

- 1-gallon jug

- 5-gallon pail

- 54-gallon drum

- 270-gallon tote