Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Ready-to-Use Product Features

- Product Highlights

- Compatible with a wide range of materials including aluminum, cast iron, steels, zinc, plastics, and composites

- Resists foaming even when contaminated with large quantities of soils or coolant. This makes CLEAN 2115AL an excellent choice where rapid buildup of coolant carryover creates a foam problem

- Many CLEAN 2115AL applications are in the range of 3,000 to 10,000 PSI (20684 to 68947 kPa)

- Provides short-term corrosion inhibition on cast iron and ferrous alloys

- Excellent biostability

- Extremely low carryoff keeps operating costs down

- Low foam and mist

- Very low initial odor level

- Exceptional sump life and great tramp oil rejection

- CLEAN 2115AL de-burrs and cleans parts in their extremely highpressure machines in one operation, a major Japanese manufacturer recommends it to their customers for use in their de-burring machines. Even at pressures up to 500 Bar, CLEAN 2115AL performs without foam or unwanted residue, for clean, well-protected parts.

- Additional Information

- Industrial Use Only

- Consult Master Fluid Solutions before using on any metals or applications not specifically recommended.

- This product should not be mixed with other metalworking fluids or metalworking fluid additives, except as recommended by Master Fluid Solutions, as this may reduce overall performance, result in adverse health effects, or damage the machine tool and parts. If contamination occurs, please contact Master Fluid Solutions for recommended action.

- Master STAGES™ is a trademark of Master Chemical Corporation d/b/a Master Fluid Solutions.

Applications & Uses

- Markets

- Applications

- Application Method

- Use Level

- 3.0 - 10.0 %

- Application Guidelines

- In very high-pressure spray washers (over 1,000 PSI, 6894.76 kPa), de-burrers or water jet cutters, typical concentrations are 3% to 5%, and operating temperatures are ambient up to 140°F (60°C). Foam may increase if the temperature is below 80°F (27°C) at the point of agitation.

- For best corrosion resistance on ferrous parts, concentration should be kept between 5% and 10%.

- CLEAN 2115AL has excellent aluminum compatibility. However, it is wise to pre-check tolerance for high temperatures (over 120°F, 50°C) or long exposure times (over 5 minutes) when washing 2000, 5000, or 7000 series wrought, or 300 series cast alloy.

- Product Applications

Applications : Corrosion inhibition, deburring, high-pressure spray washing, parts washing, VHP spray (very high pressure), vibratory, and water-jet cutting

Soils : Coolant residues

Metals : Aluminum, aluminum alloys, brass, bronze, cast iron, composites, copper, copper alloys, ferrous metals, plastics, steel alloys, steels, and zinc

Industries : Automotive- Mixing Instructions

- Recommended usage concentration in water: 3.0% - 10.0%.

- To help ensure the best possible working solution, add the required amount of concentrate to the required amount of water (never the reverse) and stir until uniformly mixed.

- Recommended Metalworking Concentrations

Design concentration range : 3.0% - 10.0%

Properties

- Odor

- Mild (Concentrate)

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Flash Point (Concentrate) | max. 216 | °F | ASTM D93-08 |

| pH (Concentrate as Range) | 8.7 - 9.1 | - | - |

| pH (Typical Operating as Range) | 8.0 - 9.0 | - | - |

| Coolant Refractometer Factor | 2.6 | - | - |

| V.O.C. Content | 0 | lbs/gal | EPA Method 24 |

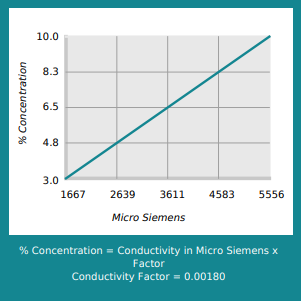

| Cleaner Conductivity Factor | 0.0018 | - | - |

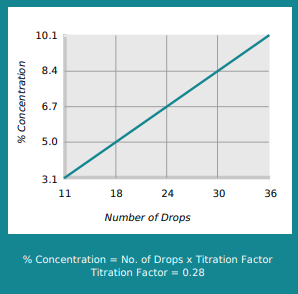

| Titration Factor | 0.28 | - | CL-1 Titration Kit |

| Number of Cleaner Vials | 2.0 | - | CL-1 Titration Kit |

| Cleaner Indicator A or B | B | - | CL-1 Titration Kit |

Regulatory & Compliance

- Product Compliance

CLEAN 2115AL is free of nitrites and silicates.

Technical Details & Test Data

- Test Data

Concentration by Conductivity

Concentration by Titration

Packaging & Availability

- Packaging Type

- Packaging

- 1-gallon jug

- 5-gallon pail

- 54-gallon drum

- 270-gallon tote