Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Plastics & Elastomers Functions

- CAS No.

- 93058-67-4, 1078142-02-5

- Technologies

- Product Families

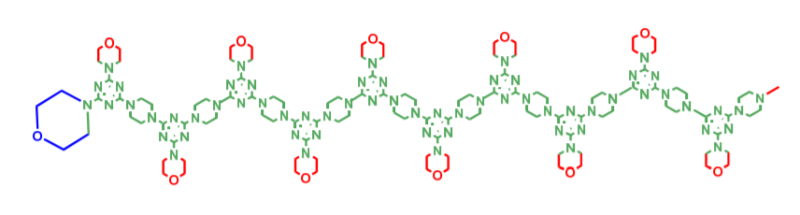

- Chemical Structure

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Recommended Applications

MCA® AP-PPMT 770 is recommended for use in polypropylene and other high-temperature polymers: A total loading of 20-25% is enough to achieve LOI > 30% & UL 94 V0 (in addition to realizing other benefits such as low smoke density and less toxic fumes) MCA® AP-PPMT 770 can also be used in polyurethane foams. It is recommended to make and use a dispersion of MCA® AP-PPMT 770 either in polyol or isocyaanate for the application.To prevent the solids from settling, the MCA® AP-PPMT 770 suspensions should be stirred or circulated by pump. The following classifications can be achieved: The mixing and processing methods customary in powder processing of polymers are adequate for the incorporation of MCA® AP-PPMT 770. Casting resins based on epoxy resins or unsaturated polyester resins achieve the classification UL 94-V0 with MCA® AP-PPMT 770.

Properties

- Appearance

- Free-Flowing, Off-White Crystalline Powder

- Insoluble in

- Water

- Physical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Melting Point (Infusible) | min. 290 | °C | — |

| Specific Gravity At 25°C | 1.72 | g/cm3 | — |

| Cl Content (w/w) | max. 0.1 | % | — |

| Water Content (w/w) | max. 0.5 | % | — |

| Aggregated Particles (Average) | 12 | μm | — |

| TGA (Weight-loss up to 300°C) | max. 2 | % | — |

| Value | Units | Test Method / Conditions | |

| Molecular Weight | Approx. 2755 | — | — |

Technical Details & Test Data

- Chemical Properties

Chemically inert and blendable with almost all additives, and particularly the HALS light stabilizers

Packaging & Availability

- Packaging Type

- Packaging

MCA® AP-PPMT 770 is delivered in 25 kg paper bags

Storage & Handling

- Transport and Storage

- ADR: no restrictions.

- ADNR: no restrictions

- RID: no restrictions

- IATA: no restrictions

- IMDG : no restrictions