Knowde Enhanced TDS

Identification & Functionality

- Technologies

Features & Benefits

- Advantages

- Reduces mercaptan content, using a strong caustic to meet mercaptan specifications and pass Doctor tests

- Allows customers to meet pipeline specification requirements for NGL, Y-grade fuels, pentane or condensate

- Simple and proven technology for sweetening light mercaptans in a hydrocarbon stream; a single vessel can achieve the RSH sweetening—no need for additional settling vessels

- Removes odorous RSH with minimal processing to meet total sulfur specifications

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Industrial Additives End Use

- Applications

- Condensates

- Light Crude Oils

- Naphtha Treating (Gasoline, Alkylate, Raffinate, Straight-Run)

- Gas Production Field

- Oil Production Field

- Crude Distillation Unit

How It Works

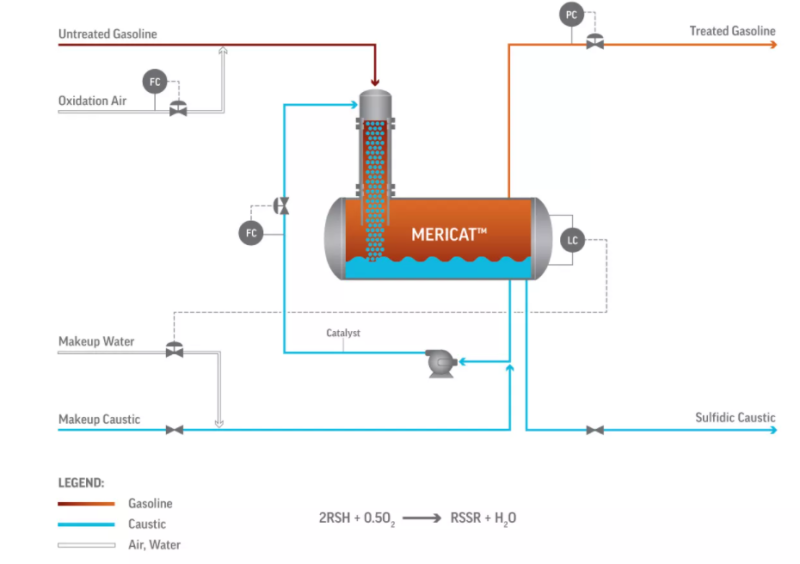

Thanks to the dramatic increase in liquid surface area achieved by Merichem’s FIBER FILM® Contactor, MERICAT™ achieves maximum efficiency of conversion—with little to no emulsification, carryover or high‑pressure drop during phase transfer.

Technical Details & Test Data

- Mercaptan Sweetening