Knowde Enhanced TDS

Identification & Functionality

- Technologies

Features & Benefits

- Advantages

- No carbon fouling or deactivation resulting in off-spec product

- Extremely effective oxidation reactor for heavy or recombinant mercaptans

- Capable of removing naphthenic acids without affecting mercaptan oxidation performance

- Uses proprietary JeSOL®-9 solution, which provides full lifecycle responsibility by Merichem®

- Eliminates effluent disposal by offering ongoing supply and return of JeSOL®-9 solution

- Used with FIBER FILM® Contactor

- Lower cost at high mercaptan levels or high throughput

- Reduced color body formation

- Can often be retrofitted into legacy carbon beds to increase capacity and treatability

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Industrial Additives End Use

- Applications

- Kerosene / Jet Fuel

- Middle Distillate Treatment

- Crude Distillation Unit

- FCCU or RCCU

- Condensates

How It Works

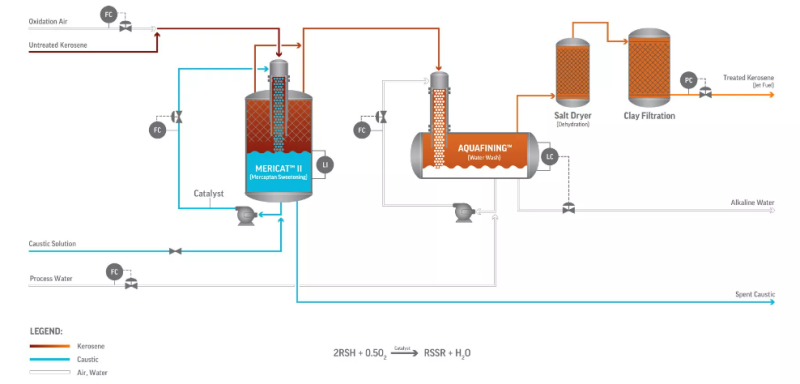

Developed by Merichem®, our proprietary FIBER FILM® Contactor device features ultra-thin, aqueous-wetted fibers that increase the surface area, resulting in significantly greater efficiency of conversion or mass transfer—with little to no emulsification, carryover or high‑pressure drop.

Technical Details & Test Data

- Kerosene Treatment Unit for Jet Fuel Production