Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 471-34-1

- EC No.

- 207-439-9

- Technologies

Features & Benefits

- Features

- Benefits

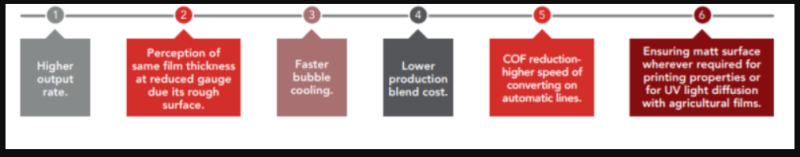

- Higher output rate.

- Perception of same film thickness at reduced gage due to its rough surface.

- Faster bubble cooling.

- Lower Production blend cost.

- COF reduction higher speed of converting on automatic lines.

- Ensuring matt surface wherever required for printing properties or for UV light diffusion with agricultural films.

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application

- Cast film (hygienic)

- High MFI blown extrusion

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Melt Index | 2 | g/10min | ASTM D1238 |

| Bulk Density | 1 | g/cm3 | ASTM D1895B |

| Density | 1.6 | g/cm3 | ASTM D792 |

| Calcium Carbonate | 73 | % | ASTM D5630 |

| Mean Particle Size | 1.89 | — | D50 |

| Top Cut | 7 | — | D98 |

| Moisture | max. 1000 | ppm | ASTM D10-7191 |