Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Plastics & Elastomers Functions

- CAS No.

- 471-34-1

- EC No.

- 207-439-9

- Technologies

Features & Benefits

- Materials Features

- Benefits

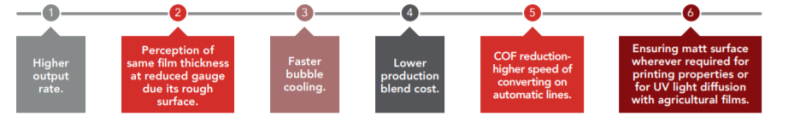

Higher output rate

Perception of same film thickness at reduced gage due to its rough surface.

Faster bubble cooling

Lower Production blend cost

COF reduction higher speed of converting on automatic lines

Ensuring matt surface wherever required for printing properties or

for UV light diffusion with agricultural films.- Features

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Application

- Sheet extrusion / Thermoforming

- Cast film

- Blown extrusion Film, High MFI

Properties

- Physical Properties

| Value | Units | Test Method / Conditions | |

| Melt Index (190°C, 2.16 kg) | 2.5 | g/10min | ASTM D1238 |

| Moisture | 1000 | ppm | ASTM D7191 |

| Bulk Density | 1.09 | g/cm3 | ASTM D1895B |

| Density | 1.83 | g/cm3 | ASTM D792 |

| Calcium Carbonate | 81 | % | ASTM D5630 |

| Mean Particle Size | 1.89 | — | D50 |

| Top Cut | 7 | — | D98 |