Knowde Enhanced TDS

Identification & Functionality

- Chemical Name

- Pharma & Nutraceuticals Functions

- CAS No.

- 9004-34-6

- EC No.

- 232-674-9

- Technologies

Features & Benefits

- Benefits

- Strong dry binder

- High dilution potential

- Excellent compressibility that allows for high tablet hardness at low compression pressure

- Promotes tablet disintegration through fast water uptake

- Facilitates low tablet friability

- Has inherent lubrication, anti-adherent and absorbent properties

- In wet granulation, promotes rapid even wetting and uniform rapid drying

- Superior physical and chemical stability

- Product Highlights

Fine particle standard type, providing excellent tablet hardness, and low friability with superior binder capacity.

Suitable for wet granulation, roller compaction, direct compression and spheronization.

Applications & Uses

- Applications

- Manufacturing Technology

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| LOD | max. 7.0 | % | — |

| Bulk Density | 0.26 - 0.34 | g/ml | — |

| Particle Size Distribution (laser test method, D10) | max. 30 | μm | — |

| Particle Size Distribution (laser test method, D50) | 45 - 75 | μm | — |

| Particle Size Distribution (laser test method, D90) | min. 110 | μm | — |

Technical Details & Test Data

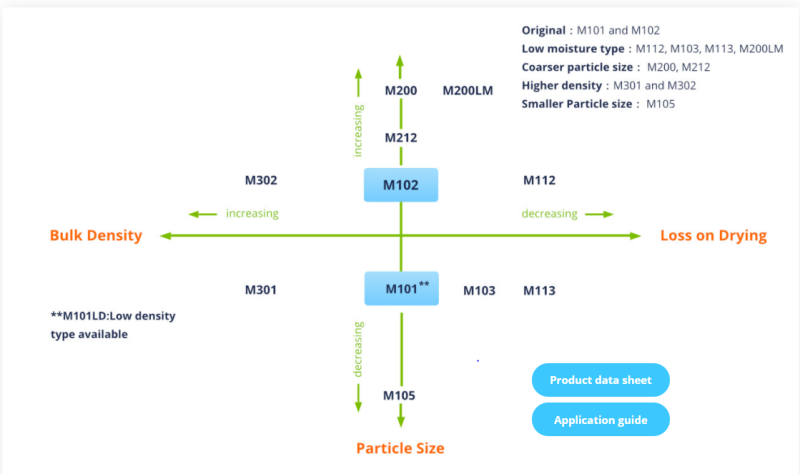

- Main areas of differentiation

- Particle Size

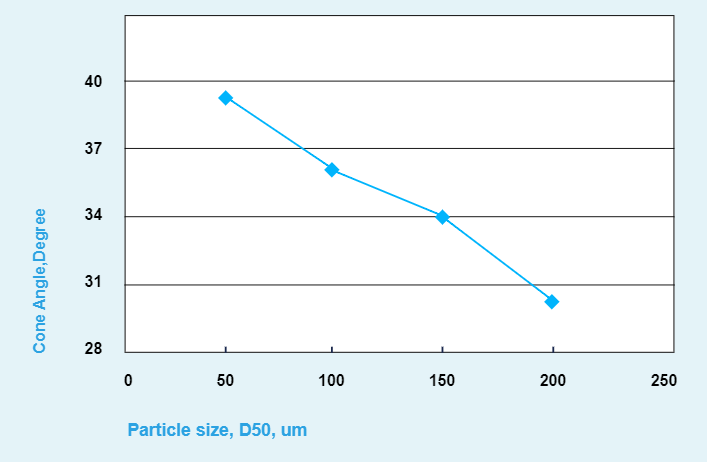

Effect of particle Size on Flowability:

Coarser particle size is associated with better flowability. Variation in powder flow during manufacturing affect the quality of the product in terms of its weight variation and content uniformity. Flow also affects manufacturing efficiency (Blending time and tableting speed).

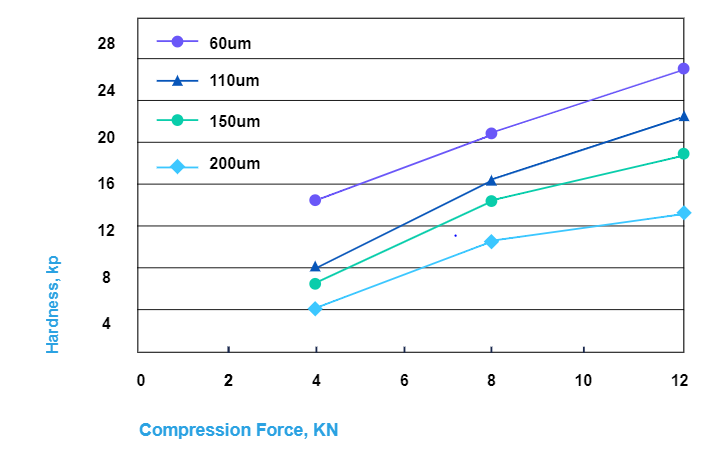

Effect of Particle Size on Tablet Compactability:

The curves in the plot of tablet hardness versus compression force represent different particle size types of Comprecel. The finer particle size type gives increasingly harder tablets.