Knowde Enhanced TDS

Identification & Functionality

- CASE Ingredients Functions

- Composite Materials Functions

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

- MITO® ACRE™ makes plastics lighter, stronger, and more durable.

- When added to recycled plastics, it prevents cracking and improves tensile, flex, and compression properties - for sustainability without sacrifice.

- Features

- MITO’s proprietary functionalization process remains scalable for different applications and industries. By functionalizing cornstarch with silica cage particles (polyoligomeric silsesquioxanes, POSS™), MITO has created a sustainable alternative to other hazardous, mined-fillers like mica.

- ACRE acts as a scaffold within the polymer, adhering substrates and bonding matrices while maintaining the same reactive dispersion characteristics as the graphene additives.

- ACRE increases functionality in composite materials through mechanical property improvements, including: tensile flex compression and adhesion–with the added benefit of optical transparency plus the potential to integrate and increase the performance of recycled materials, unlocking a variety of applications.

- Cornstarch is a renewable resource; and ACRE makes plastics lighter, more durable, and stronger. Using recycled plastics as your base material no longer means any sacrifice in performance. ACRE can even be used as a replacement for mica, a mined product.

Applications & Uses

- Applications

- Compatible Polymers & Resins

- Composites End Use

- Plastics & Elastomers End Uses

- Dispersion & Integration

MITO ACRE has been designed to seamlessly integrate into your manufacturing method:

- Shear Mixing

- Three Roll Milling

- Spray Applications

ACRE loadings depend on polymer and desired performance. Thermal and Permeability properties will be added in the future.

Properties

- Color

- Appearance

- Light yellow colored powder

- Dispersible in

- Ethanol, Isopropanol, Acetone, Tetrahydrofuran, Epoxy, Vinyl ester, Polyester

- Physical Properties

- Chemical Composition

- Physico-Chemical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength (Control) | 68.59 | Mpa | ASTM D638 |

| Tensile Strength (0.5% WT ACRE) | 79.74 | Mpa | ASTM D638 |

| Tensile Strength (% Difference at 0.5% WT ACRE) | 16 | % Mpa | ASTM D638 |

| Tensile Strength (1% WT ACRE) | 66.11 | Mpa | ASTM D638 |

| Tensile Strength (% Difference at 1% WT ACRE) | -4 | % Mpa | ASTM D638 |

| Tensile Modulus (Control) | 3.41 | GPa | ASTM D638 |

| Tensile Modulus (0.5% WT ACRE) | 3.39 | GPa | ASTM D638 |

| Tensile Modulus (% Difference at 0.5% WT ACRE) | 1 | % GPa | ASTM D638 |

| Tensile Modulus (1% WT ACRE) | 3.51 | GPa | ASTM D638 |

| Tensile Modulus (% Difference at 1% WT ACRE) | 3 | %GPa | ASTM D638 |

| Tensile Strain at Break (Control) | 2.93 | % | ASTM D638 |

| Tensile Strain at Break (0.5% WT ACRE) | 3.64 | % | ASTM D638 |

| Tensile Strain at Break (% Difference at 0.5% WT ACRE) | 20 | % | ASTM D638 |

| Tensile Strain at Break (1% WT ACRE) | 2.76 | % | ASTM D638 |

| Tensile Strain at Break (% Difference at 1% WT ACRE) | -6 | % | ASTM D638 |

| Flexural Maximum Force Withstood (Control) | 142.21 | kN | ASTM D790 |

| Flexural Maximum Force Withstood (0.5% WT ACRE) | 139.24 | kN | ASTM D790 |

| Flexural Maximum Force Withstood (% Difference at 0.5% WT ACRE) | -2 | % kN | ASTM D790 |

| Flexural Maximum Force Withstood (1% WT ACRE) | 165.59 | kN | ASTM D790 |

| Flexural Maximum Force Withstood (% Difference at 1% WT ACRE) | 14 | % kN | ASTM D790 |

| Flexural Maximum Force Withstood (2% WT ACRE) | 164.23 | kN | ASTM D790 |

| Flexural Maximum Force Withstood (% Difference at 2% WT ACRE) | 13 | % kN | ASTM D790 |

| Flexural Modulus at break (Control) | 7.8 | MPa | ASTM D790 |

| Flexural Modulus at break (0.5% WT ACRE) | 7.5 | MPa | ASTM D790 |

| Flexural Modulus at break (% Difference at 0.5% WT ACRE) | -4 | % MPa | ASTM D790 |

| Flexural Modulus at break (1% WT ACRE) | 7.9 | MPa | ASTM D790 |

| Flexural Modulus at break (% Difference at 1% WT ACRE) | 2 | % MPa | ASTM D790 |

| Flexural Modulus at break (2% WT ACRE) | 8.4 | MPa | ASTM D790 |

| Flexural Modulus at break (% Difference at 2% WT ACRE) | 8 | % MPa | ASTM D790 |

| Flexural Strain at break (Control) | 1.85 | % | ASTM D790 |

| Flexural Strain at break (0.5% WT ACRE) | 1.87 | % | ASTM D790 |

| Flexural Strain at break (% Difference at 0.5% WT ACRE) | 1 | % | ASTM D790 |

| Flexural Strain at break (1% WT ACRE) | 1.95 | % | ASTM D790 |

| Flexural Strain at break (% Difference at 1% WT ACRE) | 5 | % | ASTM D790 |

| Flexural Strain at break (2% WT ACRE) | 1.99 | % | ASTM D790 |

| Flexural Strain at break (% Difference at 2% WT ACRE) | 7 | % | ASTM D790 |

| Izod Impact Resistance (Control) | 0.099 | J/mm | ASTM D256 |

| Izod Impact Resistance (0.5% WT ACRE) | 0.12 | J/mm | ASTM D256 |

| Izod Impact Resistance (% Difference at 0.5% WT ACRE) | 0.17 | J/mm | ASTM D256 |

| Izod Impact Resistance (1% WT ACRE) | 0.126 | J/mm | ASTM D256 |

| Izod Impact Resistance (% Difference at 1% WT ACRE) | 0.2 | J/mm | ASTM D256 |

| Izod Impact Resistance (2% WT ACRE) | 0.13 | J/mm | ASTM D256 |

| Izod Impact Resistance (% Difference at 2% WT ACRE) | 0.23 | J/mm | ASTM D256 |

| Value | Units | Test Method / Conditions | |

| Oxirane, 2-([3-(trimethoxysilyl)propoxy]methyl)-hydrolyzed | max. 60 | % | — |

| Starch (From corn) | min. 40 | % | — |

| Tetrahydrofuran | max. 1 | % | — |

| Value | Units | Test Method / Conditions | |

| Bulk Density | 0.8 - 1.0 | g/cm³ | — |

Technical Details & Test Data

- Test Data

SEM 5000 X MAG

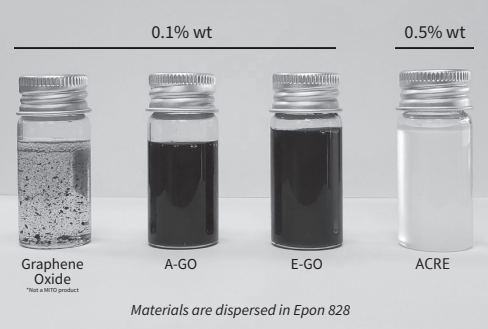

- Dispersion Comparison

Opportunity to functionally incorporate sustainability into your materials.

Packaging & Availability

- Availability

This unique additive is available in multiple formats, for limitless engineering applications.

- MITO® ACRE™ Powder - If you have dispersion equipment, this format is great for formulating epoxies, adhesives, and coatings and integrating into liquid systems.

- MITO® ACRE™ Epoxy - This format is dispersed into an epoxy system at 1% loading and sold with hardener in one-gallon and five-gallon containers.

- MITO® ACRE™ Pellets.