Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Technologies

Features & Benefits

- Labeling Claims

Applications & Uses

- Markets

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Processing

It is suggested to process BioPE EC 12 within the temperature range 190-220°C.

- Applications

- ANTISTATIC PACKAGING and TOOLS for flammable products, ammunitions, explosives, electronic parts...

- HANDLING of ELECTRONIC COMPONENTS: carrier boxes, conductive foams, carrier trays, carrier tapes...

- FILMS: antistatic and conductive films, packaging films, garbage bags...

- POWER CABLES and ACCESSORIES: insulator & conductor shield, strippable cables, jacketing…

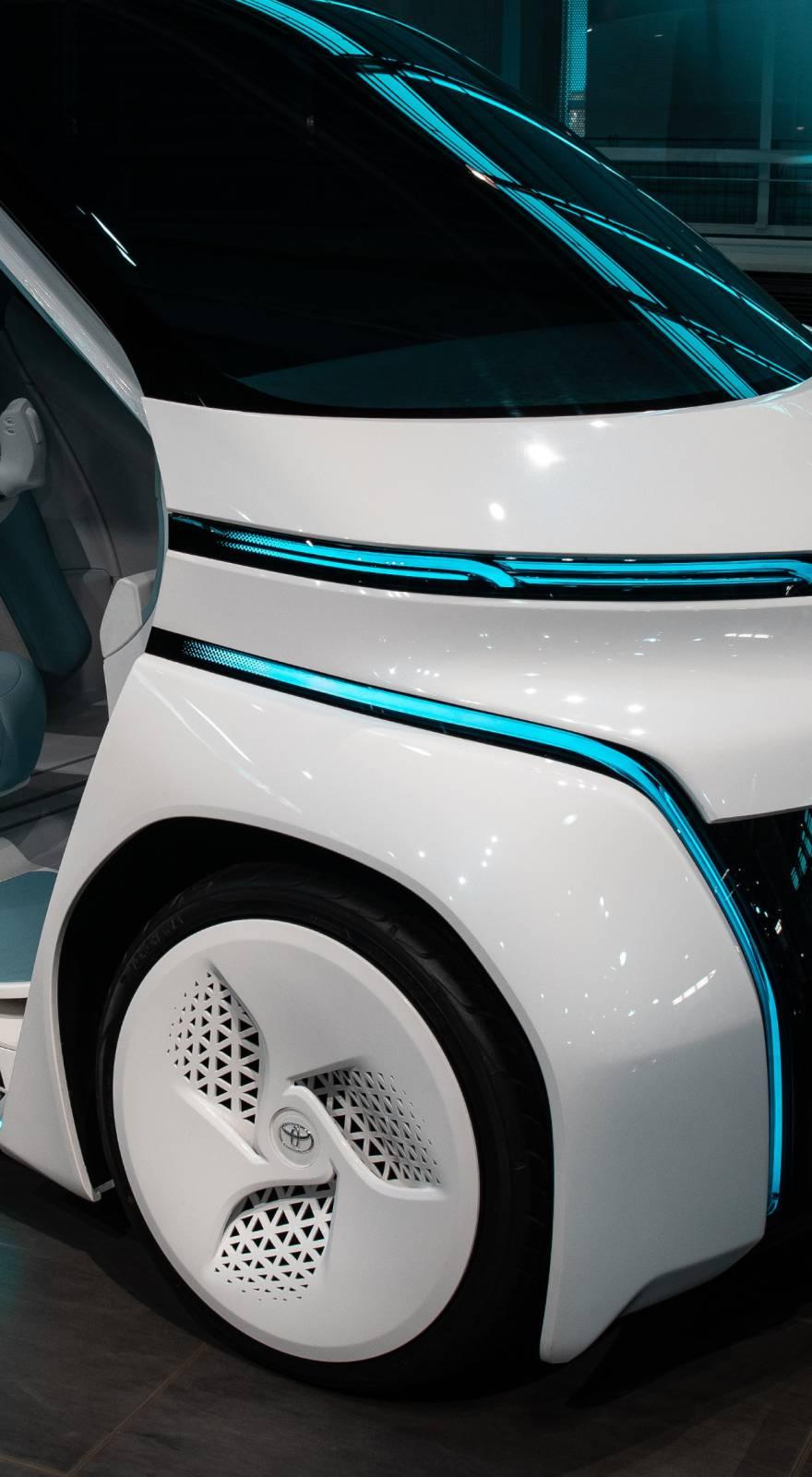

- AUTOMOTIVE INDUSTRY: fuel injection systems, anticorrosion systems, fuel tank hoses…

- TRANSPORT: mobile phone parts, elevator parts, wheels…containers, bins, pallets...

- COMPUTER, AUDIO & VIDEO: antistatic articles for computer & accessories, CD player...

Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Density | 1.2 | g/cm³ | Intern |

| MFI (210°C/2.16 kg) | 6 | g/10 min | — |

| MFR (210°C/2.16 kg) | 5 | cc/10 min | — |

| Crystalline Melt Temperature | 140 - 160 | °C | DSC |

| Glass Transition Temperature | 55 - 65 | °C | DSC |

| Processing Temperature | 190 - 220 | °C | — |

| Young Modulus | 1800 - 2000 | MPa | ISO 527-1 |

| Tensile Stress at Break | 25 - 30 | MPa | ISO 527-1 |

| Tensile Elongation at Break | 5 | % | ISO 527-1 |

| Charpy Unnotched Impact Strength | 20 | kJ/m² | ISO 179-1 (23°C ; type 1 ; Edgewise) |

| Electrical Conductivity | 12 | Ω.cm | Intern |

| Thermal Conductivity | 0.26 | W/mK | Hot Ring |

| Thermal Diffusivity | 2.6 x 10⁻⁷ | m²/s | Hot Ring |

Safety & Health

- Health

- HEALTH: medical applications, cleanroom equipment, articles for antistatic workplaces...