Knowde Enhanced TDS

Identification & Functionality

- Fillers Included

- Technologies

Features & Benefits

- Materials Features

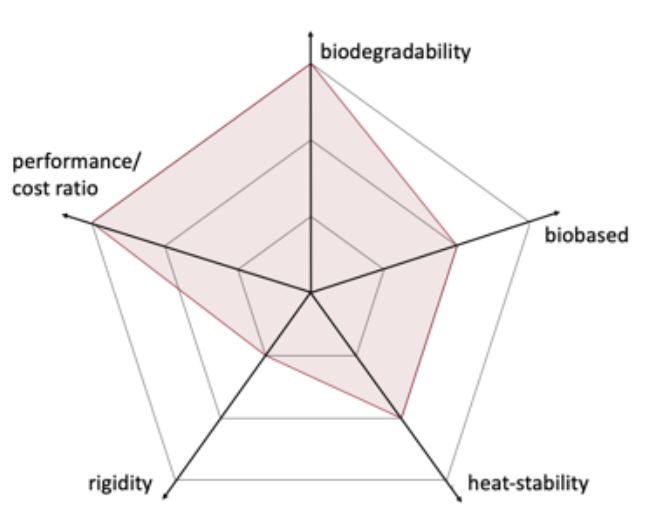

- key Characteristics

- Biopolymer compound, rice husk filled.

- Injection molding grade

- Good impact and elongation values

- Naturally heat-stable up to 65°C

- Biodegradable in controlled (e.g. Industrial compost) und non-controlled Conditions (e.g. landfill, soil, roadside)

- Food contact safe

- Dishwasher-ok

- Can be filled with bamboo powder (B), Coffee (C) or wheat husk (W) Alternatively

- Global availability

Spectabio TR45MB is a biopolymer compound. The grade is reinforced with 45 w.-% rice husk (agricultural by-product). The material can be filled with bamboo powder, coffee or wheat husk alternatively.

Spectabio TR45MB is designed to be completely biodegradable & compostable (microbial and enzymatic degradation) in the targeted disposal environment; it is biodegradable both in controlled (e.g. industrial compost factilities) and in non-controlled (e.g. soil, roadside, landfill) conditions. The grade offers a significant reduction in carbon footprint compared to traditional fossil-based plastics.

The material exhibits good impact and elongation properties. Part wall-thickness shall be greater than 1.5 mm.

- key Characteristics

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

Typical applications where Spectabio TR45MB is used for are:

- Gardening (plant pots & containers, candle housing)

- Agricultural

- Outdoor (pest control traps)

- Process Guidelines

Spectabio TR45MB can be processed on conventional injection molding equipment. The material is sensitive to moisture and high temperatures (above 190°C); high shear rates shall be avoided. The matrial needs to be dried before processing. It is recommended to use magnetic traps in the feeding system since Spectabio TR grades come with a high-filler grade of natural and agricultural by-products.

- Drying

Dry the material for a minimum of 4 - 6 hours at 80o C. A moisture content of less than 0.07% (700 ppm) is required / less than 0.10% (1000 ppm) is recommended. Avoid exposing the material to atmospheric conditions after drying; process immediately.

- Preparation

- Vacuum-out/clean hopper and air-suction system to avoid contamination.

- Clean/purge the barrel.

- Once the barrel has been cleaned, reduce barrel temperatures to the right set points (see next section).

- Introduce the compounds into the barrel only after all barrel temperatures are at target set points. The material cannot enter into the barrel when temperatures are above 190°C in any section!

- Make sure that the mold is heated up to a temperature of around 50°C.

- Start with a moderate holding pressure and keep it applied for long initially. Start with long cooling times before opening the mold.

- It is suggested to use hot runner to get better surface quality for injection molding.

- After start-up, the injection molding process shall be optimized step-by-step to industry relevant process paramaters.

Properties

- Typical Properties

- Processing Information (Injection Molding)

| Value | Units | Test Method / Conditions | |

| Density | 1.23 | g/cm3 | — |

| Melt Flow Rate (190°C/2.16 kg) | 9.4 | g/10 min | ASTM D1238 |

| Melt Flow Rate (190°C/5 kg) | 19.1 | g/10 min | ASTM D1238 |

| HDT-B (0.46 MPa) | 64.5 | °C | ASTM D648 |

| Tensile Strength (50 mm/min) | 10.6 | Mpa | ASTM D638 |

| Flexural Strength | 13.6 | Mpa | ASTM D790A |

| Flexural Modulus (1% secant) | 0.5 | Gpa | ASTM D790A |

| Elongation (50 mm/min) | 16.1 | % | ASTM D638 |

| IZOD Notched Impact Strength (at 23°C) | 64.6 | J/m | ASTM D256 |

| Mold Shrinkage | 0.4 | % | — |

| Value | Units | Test Method / Conditions | |

| Hopper Temperature | 45 | °C | — |

| Feed Zone Temperature | 160 to 165 | °C | — |

| Compression Zone Temperature | 165 to 170 | °C | — |

| Metering Zone Temperature | 170 to 175 | °C | — |

| Nozzle Temperature | 175 | °C | — |

| Mould Temperature | 50-60 | °C | — |

| Screw Speed | Low – Medium | — | — |

| Injection Pressure | Medium | — | — |

| Holding Pressure | Low – Medium / Long | — | — |

| Injection Speed | Slow – Medium | — | — |

| Cooling Time | Medium | — | — |

Storage & Handling

- Storage

Keep the material tightly closed in a dry and cool place. Keep away from heat and sources of ignition and avoid exposure to moisture, dampness. Do not store outdoors. Use material within 6 month after delivery.