Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- 3D Printing Machine Settings

Cure rate and ultimate depth of cure depend on light intensity, spectral distribution of the light source, exposure time and light transmittance of the printer window through which the light must pass.

The following working curve values were determined using a NXE400 printer.

- Directions for use

- This product is light sensitive; exposure to daylight, UV light and artificial lighting should be kept to a minimum during storage and handling.

- Shake or stir Nexa3D 3843-xABS Black well before use.

- Agitate resin before each print

- Do not leave resin in printer tray when not in use

- Recommended Post Print Processing

- Rinse the printed part using an approved cleaner to remove uncured resin

- The use compressed air or impregnated wipes to remove excess residual solvent from the surface is recommended

- Remove any support structures prior to any post-curing step

Properties

- Color

- Appearance

- Black

- Mechanical Properties

- Typical Properties

| Value | Units | Test Method / Conditions | |

| Tensile Strength at Break | 31 - 33 | MPa | ASTM D638 |

| Young’s Modulus | 1348 - 1452 | MPa | ASTM D638 |

| Elongation at Failure | 42 - 58 | % | ASTM D638 |

| Flexural Stress at Yield | 28.7 - 31.3 | MPa | ASTM D790 |

| Flexural Modulus | 1270 - 1530 | MPa | ASTM D790 |

| Flexural Strain at Break | min. 10 | % | ASTM D790 |

| IZOD Impact strength (Notched) | 50.8 - 56.8 | J/m | ASTM D256 |

| HDT (at 0.455 MPa, Vicat) | 56 | °C | ASTM D648 |

| Water Absorption | 2.35 | % | ASTM D570 |

| Value | Units | Test Method / Conditions | |

| Specific Gravity (25°C) | 1.1 | g/cm³ | — |

| Viscosity (25°C) | 450 - 750 | mPa*s | — |

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Test Data

Aging And Environmental Effects (I/III) **

LOCTITE 3D 3843 has been tested in QUV exterior weathering conditions (ASTM G-154) for 800 hours with less than a 15% change in Tensile and IZOD Impact properties.

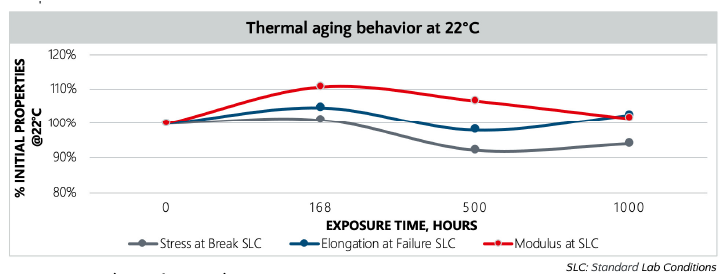

Control Aging at 22°C (Tested at 22°C)

Samples were kept at standard laboratory conditions and were not exposed to elevated temperatures.

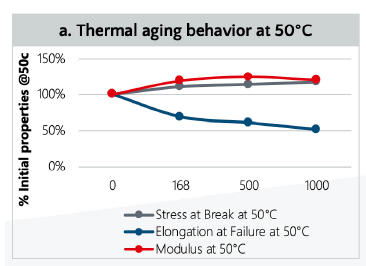

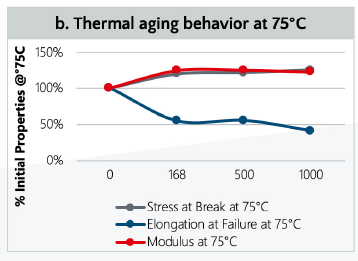

Heat Aging (Tested at 22°C)

Samples were aged at (a) 50°C and (b) 75°C.

*All values tested at room temperature

** Data based on testing by Henkel

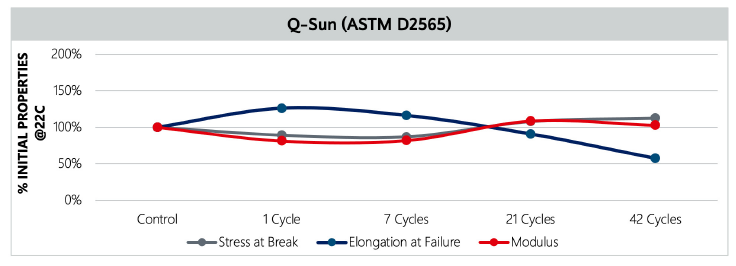

Q-Sun (ASTM D2565)**

CHEMICAL RESISTANCE

Amount of Exposure Time 100 hours% of initial strength Chemical Measure Elongation at Break Stress at Break Modulus Water (22C°) % 152 52 44 IPA % 117 40 38 NaOCl % 120 57 58 Salt Fog (22C°) % 169 43 30 Motor Oil (87C°) % 93 104 100 Hydrogen Peroxide

158 47 38 CHEMICAL RESISTANCE

Amount of Exposure Time 500 hours% of initial strength Chemical Measure Elongation at Break Stress at Break Modulus Water (22C°) % 175 52 12 IPA % 0 0 0 NaOCl 5 % 83 28 31 Salt Fog (22C°) % 192 33 17 Motor Oil (87C°) % 78 106 105 Hydrogen Peroxide

180 22 7 ** Data based on testing by Henkel

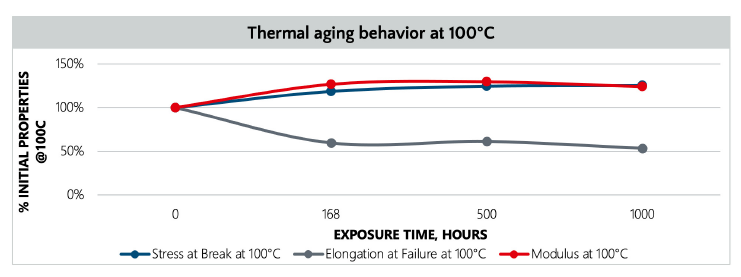

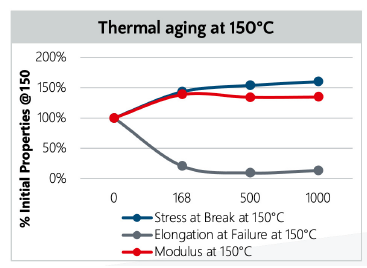

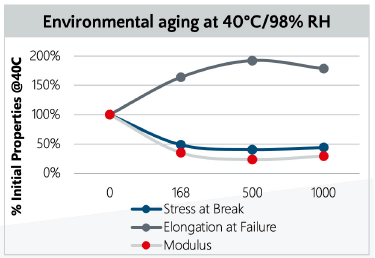

Aging And Environmental Effects (I/III) **

Heat Aging at 100°C (Tested at 22°C)

Samples were aged at the temperature indicated, and tested at 22°C.

Heat Aging at 150°C (Tested at 22°C)

*All values tested at room temperature

** Data based on testing by Henkel

Storage & Handling

- Storage Information

- Store product in the unopened container in a dry location.

- Storage information may be indicated on the product container labeling.

- Optimal Storage : 8°C to 21°C.

- Storage below 8°C or greater than 28°C can adversely affect product properties.

- Material removed from containers may be contaminated during use. Do not return product to the original container. Nexa3D cannot assume responsibility for product which has been ontaminated or stored under conditions other than those previously indicated.