Knowde Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

- Composition

Urethane polymer, Water

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Characteristics

- Polycarbonate-Polyurethane: Excellent heat resistance and hydrolysis resistance.

- Non-yellowing type Polyurethane: Prevents yellowing and deterioration caused by heat and light.

- Water-based Urethane: Less load on exhaust system / wastewater system compared to solvent type. It reduces environmental burden.

- Soap-free type: It prevents bleeding and slow film formation caused by surfactant.

- Film characteristic: Durable and strong film offers excellent abrasion resistance.

Applications & Uses

- Applications

- Coating Type

- Applications

- Floor maintenance

- Paint binder

- Inkjet

- Steel sheets & metals

Properties

- Color

- Physical Form

- Appearance

- White liquid

- Soluble in

- Water, Cold water, Alcohol

- Typical Properties

- Film Properties

| Value | Units | Test Method / Conditions | |

| Particle Size | approx. 30 | nm | — |

| pH (undiluted) | approx. 8 (undiluted) | — | — |

| Solid Content | approx. 35 | % | — |

| Viscosity (at 20℃) | max. 500 | mPa.s | — |

| Value | Units | Test Method / Conditions | |

| Breaking Strength | 50 | Mpa | — |

| Elongation at Break | 50 | % | — |

| Glass Transition Point | 60 | °C | — |

Technical Details & Test Data

- Test Data

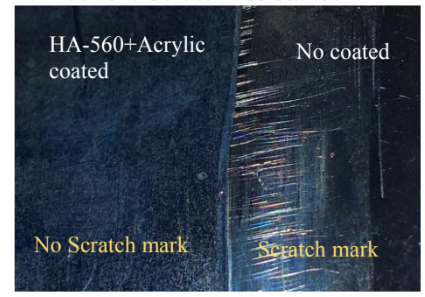

- Excellent Scratch resistance

Using brass brush for Scratch test

PC ABS PET PMMA HA-560 + F HB HB 2H Acrylic 2B B B B

For acrylic emulsion the surface hardness increases, and the quality will be improved by adding HA-560

- Excellent Corrosion resistance

Corrosion Resistance Moisture Resistance Water stain Resistance Sweat Resistance

EVAFANOL HA-560 Exellent Good Exellent Average Existing urethane Bad Good Good Bad Test Corrosion Moisture Water mark Perspiration Test methods Salt spray test (JIS Z2371) 80°C×RH98%×24hrs Drop DI water and dry Place artificial perspiration 40°C×RH80%×96hr.

Criteria No white rust after 240hrs L=<60 after test No water mark No discoloration

Good salt water resistance. Can be used as a metal surface chemical conversion film.

Suitable as galvanized steel sheet and upper layer film.