Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Usage

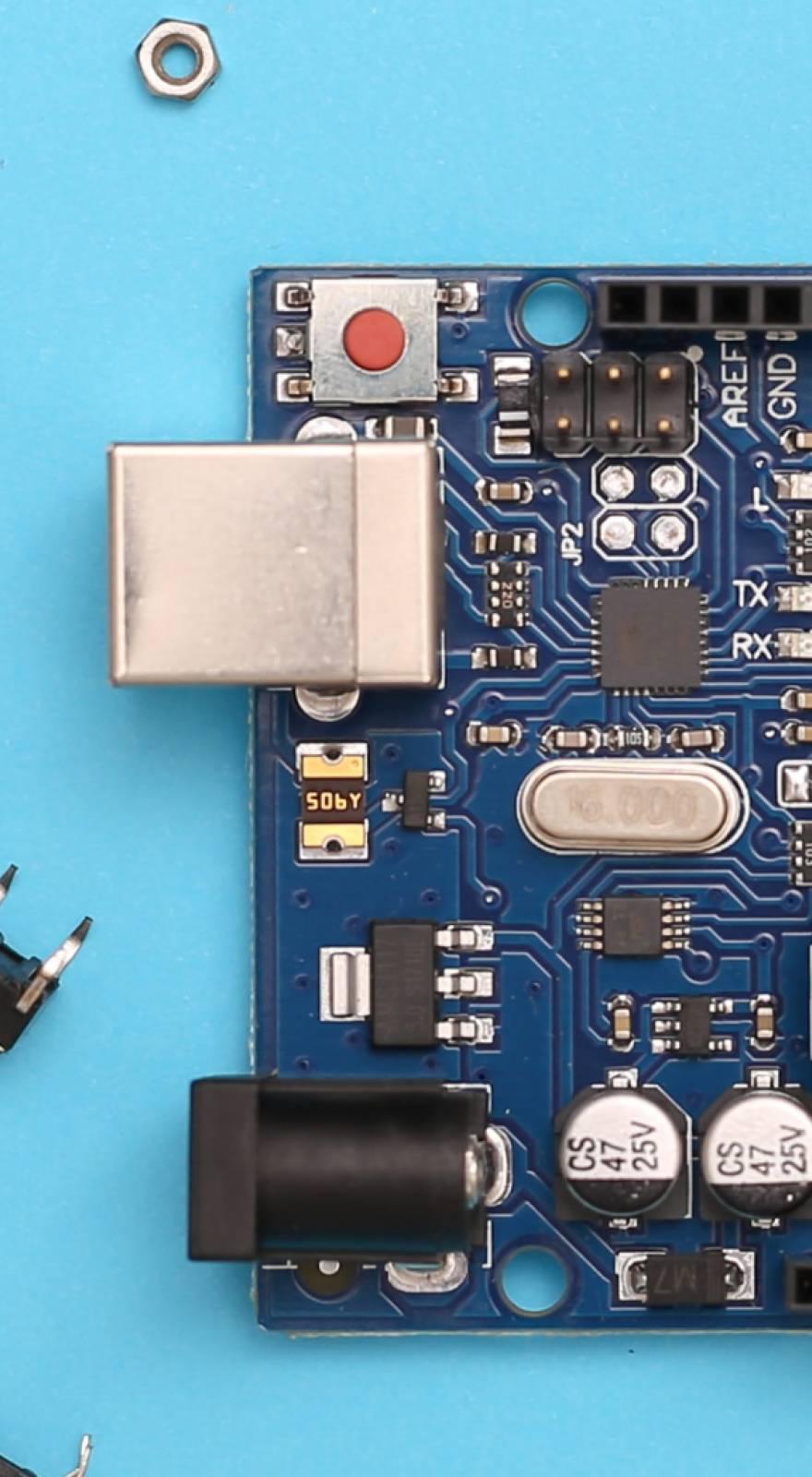

Substrate Potting

Properties

- Appearance

- Black liquid

- Typical Properties

- Notes

Standard Curing Condition:80 °C- 2 hours

| Value | Units | Test Method / Conditions | |

| Specific Gravity (25°C) | 0.92 | — | — |

| Viscosity (25°C) | 1700.0 | mPa.s | — |

| Mixing Ratio (25°C) | 100/30 | — | — |

| Mixed Viscosity (25°C) | 1200.0 | mPa.s | — |

| Mixed Specific Gravity (80°C) | 0.95 | ー | — |

| Gel Time Parts by Weight | 35.0 | min | — |

| Pot Life (25°C, time up to 10Pa.s) | 60.0 | minute | — |

| Hardness (25°C) | 25.0 | Shore A | JIS K-7312 |

| Hardness (25°C) | 4.0 | — | Arsker C2 |

| Glass Transition Temperature (TMA) | -50.0 | °C | — |

| Coefficient of Thermal Expansion below Tg | 4.63 x 10-4 | °C | — |

| Coefficient of Thermal Expansion above Tg | 7.8 x 10-5 | °C | — |

| Tensile Strength (25°C) | 250.0 | MPa | JIS K-7312 |

| Elongation (at break 25°C) | 5.1 x 1012 | % | JIS K-7312 |

| Young's Modulus (25°C) | 0.2 | MPa | JIS K-7312 |

| Volume Resistivity (25°C) | 0.45 | Ω・cm | JIS K-6911 |

| Dielectric constant (1kHz 100kHz 1MHz) | 5.4 4.5 4.0 | — | JIS K-6911 |

| Dielectric Loss Tangent (1kHz 100KHz 1MHz) | 2.4 8.2 9.2 | % | JIS KL6911 |

| Breakdown Voltage (23°C 50%RH) | 16.0 | kV/mm | JIS C-2110 |

| Waer Absorption (boil for 1hr) | 0.47 | wt% | JIS K-6911 |

| Waer Absorption (25°C 24hrs) | 0.64 | wt% | JIS K-6911 |

| Cure Shrinkage (190g, 25°C) | 0.79 | % | NPST-1 5.6(B) |