Knowde Enhanced TDS

Identification & Functionality

- Backing Material Type

- Product Type

- Technologies

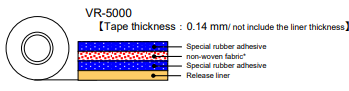

- Structure

Features & Benefits

- Ready-to-Use Product Features

- Feature

- Offers excellent adhesion for various substrates by using the special rubber adhesive.

- Offers superior repulsion property.

- Ten restricted substances by RoHS are not contained.

- Superior converting and handling performance in a die cut process.

Applications & Uses

- Markets

- Compatible Substrates & Surfaces

- Application

- Bonding of metals plates, plastic plates, rubbers and foams.

- Bonding of parts in: Printers, Copiers, Televisions, Other office equipment and Home appliances

- Fixing parts of digital camera - High adhesion to rubber

- Fixing brash of vacum cleaner - High adhesion without primer

- Fixing parts of toner cartridges - High repulsion resistance

- Usage Precautions

- Remove all oil, moisture and dirt from the surface of the substrate before applying.

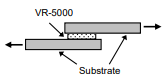

- Since the tape is pressure-sensitive adhesive, be sure to apply enough pressure with a roller or press when applying. Otherwise it might be affected to its properties and appearance.

- The tape may not adhere well to extremely uneven or distorted surfaces. Enough Leveling off the surface should be required before applying.

- It takes certain time to get full adhesive strength after applying, keep away the tape from any stress for a several hours after applying.

- Depending on a rubber material, there may be a risk of affecting adhesive property over time due to migration of component from rubber material. Please conduct a thorough evaluation in advance, on initial adhesive strength and its change over time.

- This product uses a rubber adhesive, which is easily affected by heat and oxygen compared to acrylic adhesive. Please conduct a thorough evaluation in advance on initial adhesive properties and its change over time, to determine application area and usage.

Properties

- Typical Properties

- Properties

180 degree peeling adhesion for each substrate

Substrate VR-5000 Stainless steel plate 30 Aluminum plate 29 ABS plate 31 PCABS plate 31 Polystyrene plate 32 HIPS plate 32 Polycarbonate plate 32 Polypropylene plate 30 Polyacetal plate 32 Polyethylene plate 15 Polyurethane foam 9 EPT rubber 10 CR rubber 12

(Unit:N/20mm)

Tape area :20mm width

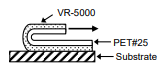

Lining material :PET#25

Pressing condition :1 pass back and forth with a 2-kg roller at 23 degree C, 50% RH

Applying condition :23 degree C/50%RH × 30min

Peeling speed :300mm/min

Peeling angle :180 degree

Measurement temp :23 degree C, 50%RH

180 degree peeling strength for each temperature

Temperature VR-5000 0 degree C 25 23 degree C 30 40 degree C 29 60 degree C 23

(Unit:N/20mm)

Substrate :Stainless steel plate

Tape area :20mm width

Lining material :PET#25

Pressing condition :1 pass back and forth with a 2-kg roller at 23 degree C, 50%RH

Applying condition :Each temperature for 30min

Peeling speed :300mm/min

Peel angle :180 degree

Measurement temp :0,23,40,60 degree C

Shearing adhesive strength for each substrate

Substrate VR-5000 Stainless steel plate 721 Aluminum plate 473 ABS plate 330 Polystyrene plate 300 Polycarbonate plate 300

(Unit:N/20mm×20mm)

Tape area :20mm×20mm

Pressing condition :1 pass back and forth with 5-kg at 23 degree C/50%RH

Applying condition :23 degree C/50%RH×30min

Peeling speed :50mm/min

Measurement temp :23 degree C/50%RH

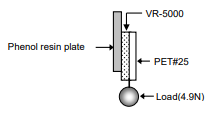

Holding power

Temperature VR-5000 23 degree C 0.1 40 degree C 0.2 60 degree C 0.2

(Unit:mm/hr)

Substrate :Phenol resin plate

Lining material :PET#25

Pressing condition :1 pass back and forth with 2-kg at 23 degree C/50%RH

Applying condition :23 degree C/50%RH×30min

Tape area :20mm×10mm

Load :4.9N(500gf)

Load time :1hr

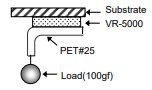

Static load peeling

Substrate VR-5000 Stainless steel plate 0.5 ABS plate 1.1 Polystyrene plate 1.1 Polypropylene plate 0.5

(Unit:mm)

Tape area :10mm×50mm

Backing material :PET#25

Pressing condition :1 pass back and forth with a 2-kg roller at 23 degree C/50%RH

Applying condition :23 degree C/50%RH×30min

Load :0.98N(100gf)

Application temp :23 degree C/50%RH

Load time :24hrs

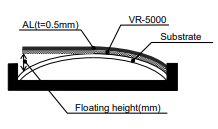

Resistance to repulsion for plastic plate

Substrate VR-5000 ABS plate <1 Polypropylene plate <1 Polystyrene plate <1

(Unit:mm)

Tape area :20mm×180mm

Substrate size :30mm×200mm

Lining material :AL(t=0.5mm)

Pressing condition :23 degree C/50%RH

Applying condition :23 degree C/50%RH for 24 hrs

Repulsion condition: Laminate a substrate and AL plate with tape by laminating machine. Fit the left sample into wooden mold then leave it at 70 degree C x 72 hrs and measure the floating height.180 degree peeling adhesion -Aging(durability) at each condition after applying

Condition VR-5000 Initial(23 degree C/50%RH×30min) 30 -30 degree C×30 days 34 80 degree C

14 days 35 30 days 35 40 degree C/92%RH×30 days 37 60 degree C/95%RH×30 days 38 Heat shock[100cycle] *1 35 Heat cycle[40cycle]*2 37 *1:Heat shock condition [-40 degree C × 30min⇔90 degree C × 30min] 100cycle

*2:Heat cycle condition [-20 degree C × 6hr ⇒ (1hr) ⇒ 60 degree C/95%RH × 6hr ⇒ (1hr) ⇒] 40cycle

(Unit:N/20mm)

Substrate :Stainless plate

Lining material :PET#25

Pressing condition :1 pass back and forthwith 2-kg roller at 23 degree C/50%RH

Applying condition :Refer to the left table

Peeling speed :300mm/min

Peeling angle :180 degree

Measurement temperature :23 degree C/50%RH

| Value | Units | Test Method / Conditions | |

| Thickness | 0.14 | mm | - |

| 180° Peeling Force | 30.0 | N/20mm | - |

Safety & Health

- Safety Precaution

- Take a careful consideration if this product is adapted to the use, purpose and condition before using. The tape may peel in some cases depending on substrate and attachment conditions.

- When using this product in areas that may pose a risk of accident, use together with a different joining method.

Packaging & Availability

- Sizes

Tape thickness(mm) Width(mm) Length(M) 0.14 5 - 1200 50

Storage & Handling

- Storage Precautions

- Make sure to store this product in a box.

- Avoid storing in high-temperature or high-moisture areas. This product should be stored in a cool, dark area away from direct sunlight.

- Please use this tape within 6 months of storage.