Knowde Enhanced TDS

Identification & Functionality

- Product Type

- Technologies

- Product Families

Features & Benefits

- Ready-to-Use Product Features

Applications & Uses

- Markets

Technical Details & Test Data

- General Properties of Norland Photoengraving Glue

Norland Photoengraving Glue is supplied at a 45% solids solution with a viscosity in the range of 4000-5000 centipoise, or similar to honey. The glue as supplied is protected with a bactericidal agent that will give it a long shelf life. Preferred storage temperature is 75°F (24°C) or less, away from exposure to heat or direct sunlight. Like all colloid solutions, the viscosity is dependent upon temperature. Photoengraving glue becomes more viscous as the temperature is reduced, and will form a gel at temperatures below 50°F (10°C). If the cold or gelled glue is heated to room temperature, the viscosity will return to normal with no chemical change. If the glue arrives frozen or gelled because of winter temperatures, store at room temperature for a day before use so that it can be poured out of the container. Photoengraving glue is a protein that is an excellent food for bacteria. The glue as supplied is

protected. Diluting will reduce the effectiveness of the preservative, and non sterile water will provide the bacteria culture necessary to start a vigorous growth within a few days. The addition of bichromate will act as a preservative and effectively stop any bacterial action. The above is pointed out so that the user will not predilute large quantities of photoengraving glue. Dilute only enough to make the photo resist.

- Chemistry

Fish gelatin is a protein molecule consisting of a complex chain of 20 amino acids. The molecular weight of fish gelatin (or photoengraving glue) is estimated to be between 30,000 and 60,000. The specific properties of the molecule are dependent upon its molecular chain length and the reactive end groups that are on the molecule. These reactive groups are hydroxy (OH), carboxy (COOH), and amino (NH2)

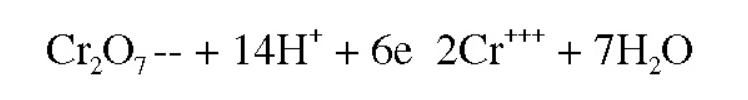

The photo hardening of dichromated colloid layers has been studied at some length over the past years. The literature contains considerable reference to various explanations. We would suggest the photo hardening to be the result of an oxidation-reduction reaction that is accelerated by light in the ultraviolet wave length range. The oxidation-reduction equation for bichromate is as follows:

Under the action of light, the colloid is oxidized by the bichromate, and trivalent chromium is formed. Since trivalent metal ions will gel a colloid, the resultant areas exposed to light will not wash away when the colloid layer is rinsed with water.

The sensitivity of the coating is dependent upon these factors:

1. The composition of the coating.

The coating composition requires a colloid that reacts with bichromate under ultraviolet light and cross links with resultant trivalent chromium to form a gel.

2. The thickness of the coating.

Since the light must penetrate and insolubilize the coating to the interface of the surface coated, the thickness is important. Otherwise there will be no adhesion.

3. The distance of the light from the coating.

This determines intensity at the photo resist surface.

4. The wave length of the light source.

The light source must have the proper wave length that is absorbed by the photo resist.

5. The time of exposure.

The time of exposure (together with intensity) determine the total light energy.

In forming a dichromated colloid image on a metal surface, it is necessary to obtain a gelled image that will not readily wash away. Insufficient exposure will result in insufficient trivalent ions being formed. The resultant image will not form a hard gel but will swell and sluff off when washed with water. Sufficient exposure must be made so the image will not swell excessively upon washing, and then will dry down to a glossy coat.

The ratio of bichromate to colloid will also affect the sensitivity. For photoengraving glue, the ratio can be varied from 1 part ammonium bichromate/ 20 parts liquid glue (by weight as supplied) to 1 part ammonium bichromate/ 7 parts liquid glue. The sensitivity will increase as the bichromate concentration is increased, reaching a peak at about 1 part ammonium bichromate/ 10 parts liquid glue weight. Additional bichromate concentration will reduce the sensitivity, because the light will not penetrate the coating as deeply.

Only a small percentage of the bichromate reacts with the colloid. The remainder is washed out during the image development step. However, the excess amount is necessary to obtain the proper sensitivity.

Safety & Health

- Safety Precautions

Although bichromates, acids, and alkalies are used in many production processes every day, we wish to point out that care should be exercised to avoid contact of these materials with the skin and eyes. A good safety procedure is to use rubber gloves and rubber apron when handling these materials and safety goggles when there may be danger of splashing.

Photoengraving glue is non-toxic by itself, but the bichromate resist should be handled in such a manner as to avoid undue skin contact..