Knowde Enhanced TDS

Identification & Functionality

- Ingredient Name

- Food Ingredients Functions

- Ingredients

- Microcrystalline Cellulose

- Food Additive Number

- E 460(i), INS 460(i)

- Technologies

- Product Families

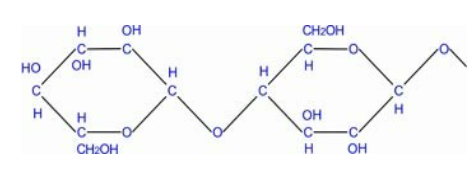

- Chemical Structure

Features & Benefits

- Food Ingredients Features

- Product Highlights

Most of fiber-rich plants contains hemicellulose, lignin, glucose, and cellulose. By going through hydrolysis process, cellulose is collected to be further processed. The insoluble crystalline fraction in each microfibril of cellulose is than extracted to make Microcrystalline Cellulose. Finally, MCC is co-polymerized with other hydrocolloids to create a stabilizer with a unique characteristics, commonly called Colloidal Grade MCC.

- MCC Quick Facts

- Microcrystalline Cellulose (MCC) is made of plant fiber (Cellulose). Cellulose is an insoluble and indigestable (Therefore non-caloric) dietary fiber.

- There are two grades of MCC: Pure MCC for pharmaceutical use and MCC Colloidal grade for stabilizing system in food.

- FibroTec MCC is a Colloidal MCC that mainly functions as food stabilizer or hydrocolloid.

- FibroTec MCC optimizes products such as milk products, ice cream, beverages, donuts and bakery, sauces and dressings, etc.

- Using FibroTec MCC as a your choiced stabilizer will give many advantages. To make an optimal stabilizing system, NNT recommends combining FibroTec MCC with other hydrocolloids such as Carrageenan, Pectin, Gellan Gum, Alginate, LBG, Guar Gum, Xanthan Gum, etc.

Applications & Uses

- Markets

- Applications

- Food & Nutrition Applications

- FibroTec in Your Products

Adding FibroTec in your product has many benefits. It optimizes the functionality of other ingredients to give you the best performance in you products. FibroTec gives you these benefits by creating a three-dimensional matrix with water or other liquid media. This network suspends and traps particles to prevent any ingredient separation, color separation and moisture migration.

To take full advantage of the functionality of FibroTec, it is essential to first let FibroTec to develop its weak gel network with the liquid media by mixing it well with the main ingredient of the product. In liquid products, it is necessary to disperse FibroTec in a high-speed mixer. Furthermore, using a homogenizer for product dispersion will help FibroTec to function at its best.

In a semi-solid products, it is also best to disperse FibroTec in liquid before adding other ingredients. When adding FibroTec in your product, it is advised to add salt, acid and calcium at the end of the process.

- Dairy Products

The presence of milk fat, lactose, calcium, vitamins, mineral and salts, protein and enzyme in milk creates a very complex structure in dairy products. The additional of other ingredients in many different dairy products sometimes resulting in instable product. Such complicated system requires accurate processing and stabilizing system. Microcrystalline Cellulose (MCC) is a key stabilizer for dairy. Not only MCC suspends solids and eliminates separation and sedimentations, it adds mouth-feel and creaminess in dairy.

- Applying FibroTec in Dairy Beverages

- There is no single stabilizer can be applied in dairy as a stand-alone stabilizer. Finding the correct blending of FibroTec MCC and other stabilizers and emulsifier is very important. When applying FibroTec based stabilizing system, it is recommended to disperse it in liquid media at 2000RPM and at temperature of 50-70C. Homogenization is necessary for final step before sterilization. Different characteristics of products require different pressure setting. Lastly, it is recommended to add calcium, vitamins, acid and salt at the end after all other ingredients are added.

- There is no single stabilizer can be applied in dairy as a stand-alone stabilizer. Finding the correct blending of FibroTec MCC and other stabilizers and emulsifier is very important. When applying FibroTec based stabilizing system, it is recommended to disperse it in liquid media at 2000RPM and at temperature of 50-70C. Homogenization is necessary for final step before sterilization. Different characteristics of products require different pressure setting. Lastly, it is recommended to add calcium, vitamins, acid and salt at the end after all other ingredients are added.

- Key Functionalities

- Stabilizes Product

- Emulsifies Milk Fat

- Adds Creaminess

- Improves Mouth-feel

- Reduces Fat

- Carries Color

- Produces No Unwanted Gel

- Controls Flow

- Stable in Any Temperature

- Applications

- Flavored Liquid Milk

- Chocolate Liquid Milk

- Fortified Milk

- Sweet Condensed Milk

- Yogurt & Yogurt Drinks

- Whipping Cream

- Butter and Margarine Blends

- Processed Cheese

- Applying FibroTec in Dairy Beverages

- Ice Cream

Ice Cream is the favorite dessert of the world. Technically, there are so many different kinds of ice creams. Premium ice cream, flavored ice cream, sub-par ice cream, soft-served ice cream, gelato, etc. Microcrystalline Cellulose (MCC) is a key stabilizer in ice cream. Not only MCC increases ice cream's melting point and eliminates ice crystal, it adds mouth-feel and creaminess.

- Applying FibroTec in Ice Cream

- It is recommended to create the correct stabilizing system of FibroTec MCC and other stabilizers and emulsifier to your ice cream products. When applying FibroTec based stabilizing system, it is recommended to disperse it in liquid media at 2000RPM and at temperature of 50-70C. Homogenization is necessary for final step before sterilization and aging. Different characteristics of products require different pressure setting. Lastly, it is recommended to add calcium, vitamins, acid and salt at the end after all other ingredients are added.

- Key Functionalities

- Stabilizes Product

- Increases Melting Point

- Eliminate Ice Crystals

- Improves Mouth-feel

- Adds Creaminess

- Improves Texture

- Produces No Unwanted Gel

- Controls Flow

- Stable in Any Temperature

- Applications

- Flavored Ice Cream

- Premium Ice Cream

- Gelato

- Soft-served Ice Cream

- Non-Dairy Ice Cream

- Applying FibroTec in Ice Cream

- Donuts & Bakery

Donuts, bakery & Pastries

FibroTec acts as a dough optimizer in bakery products. It retains water, reduces oil absorption, and strengthens dough structure while softens the dough structure. In result, FibroTec optimizes dough performance and improves product's shelf-life.

Glazings, Icings, and Fillings

In Glazing and Icing, FibroTec has a unique function. It creates network between liquid and sugar to ensure the smoothness of the glaze. The weak network created also ensures that glazings will not overly hardened and not easily cracked. With the right combination of emulsifier and protein, FibroTec can also increase the melting point of glazings and icings.

- Applying FibroTec in Dough

- It is recommended to create the correct stabilizing system of FibroTec MCC and other emulsifier to your dough products. When applying FibroTec, it is recommended to disperse in liquid media at 2000RPM and at temperature of 50-70C before mixing flour and other ingredients.

- Key Functionalities

- Stabilizes Product

- Prevents Moisture Migration

- Reduces Fat Absorption

- Improves Mouth-feel

- Improves Texture

- Improves Elasticity

- Enhances Breadcrumb

- Carries and Enhances color

- Longer Shelf-life

- Applications

- Donuts

- Bakery and Breads

- Pastries

- Cakes & Desserts

- Glazing, Fillings, and Icings

- Applying FibroTec in Dough

- Beverages

Different beverages have different characteristics and require different processes and ingredients. FibroTec MCC, blended with other hydrocolloids will stabilize ingredients in beverages against calcium, protein, oil, solid particles, acidic condition, and temperature change. FibroTec not only helps stabilizing beverages, it creates a unique and desirable mouth-feel and texture to give consumer a better refreshing drink.

- Applying FibroTec in Beverages

- It is recommended to create the correct stabilizing system of FibroTec MCC and other hydrocolloids & emulsifiers to optimize your product. Different beverages may require different combinations of hydrocolloids.

- When applying FibroTec, it is recommended to disperse it in liquid media at 2000RPM and at temperature of 50-70C before other ingredients. Calcium, salt, and acids is best added last. Selecting the right kind of sweetener will also affect the beverage's stability.

- Some beverages will require multi-stage homogenization process. Different beverages require different pressures. The production procedures and processing are as critical as the stabilizing system for the overall performance of product.

- Key Functionalities

- Stabilizes product

- Enhances body and thickness

- Adds creaminess

- Improves Mouth-feel

- Improves texture

- Suspends solid

- Carries and enhances color

- Flow Control

- Applications

- Fruit and Healthy Drinks

- Soymilk

- High Protein Smoothies

- Coffee Drinks

- Milk Tea

- Applying FibroTec in Beverages

- Fried & Processed Food

Fried and Baked Products

Nothing is more satisfying than a bite of a perfect crisp of baked and fried food. The most critical attribute for a savory product is fat and oil absorption. Excessive amount of oil absorbed shortens the length of shelf-life significantly. FibroTec MCC creates a weak network of protection with its liquid media. This network could repel excessive oil to reduce oil intake and fat absorption, therefore delaying rancidity and increases crispiness.

Processed Meat

FibroTec in processed meat mostly functions as optimization of the whole elmulsifying and stabilizing system. Although the most commonly used hydrocolloid in meat process is Alginate and Carrageenan, adding FibroTec MCC will further increase binding ability therefore reduces the risk of synerisis. FIbroTec's unique fat-like mouthfeel will also enhance the desired mouth-feel and texture.

- Applying FibroTec in Processed Food

- It is recommended to disperse FibroTec in milk or water at a speed of 2000-15000RPM before adding flours, and other solid and semi-solid ingredients. Protein, calcium, and salt should be added last.

- Key Functionalities

- Reduces Fat Absorptions

- Reduces Oil Usage

- Retains Moisture

- Delays Rancidity

- Prevents Syneresis

- Binds All Ingredients

- Improves Mouth-Feel

- Improves Texture

- Carries and Enhances Color

- Applications

- Fried, Battered, Breaded

- Cookies, Crackers, & Snacks

- Corned, Canned Minced Meat

- Sausages, Meatballs, etc.

- Applying FibroTec in Processed Food

- Sauces and Dressings

The most essential condiment to adding flavor to our food is sauce and dressing. However, we find that ready-to-use sauces and dressings available today have problems of separation, change of texture, and synerisis due to temperature change. FibroTec MCC creates a weak network of protection with its liquid media. This network could prevent separation, moisture migration, synerisis, and suspend solid in sauces and dressings. It can also add body and creaminess to improve mouth-feel and texture.

- Applying FibroTec in Sauces and Dressings

- FibroTec MCC generally is applied on sauces and dressings with combinations of other hydrocolloids such as xanthan gum, CMC, or guar gum.

- It is recommended to disperse FibroTec based stabilizing system in 50 to 70C of milk or water at a speed of 2000-15000RPM, before adding other ingredients. Salt and acidic materials should be added last.

- It is also essential that products are cooled and shaken well after any sterilization process.

- Key Functionalities

- Thickens, Stabilizes Product

- Prevents Synerisis

- Suspends Solids

- Adds Body

- Adds Creaminess

- Retains Moisture

- Improves Mouth-feel

- Improves Texture

- Carries and Enhances Color

- Applications

- Chili Sauce

- Barbeque Sauce

- Salad Dressings

- Cheese Sauce and Spreads

- Applying FibroTec in Sauces and Dressings

- Pasta and Noodles

FibroTec offers rheological benefits in pasta and noodle applications. The ability of FibroTec MCC to form an extensive nework has been proven to add desirable sensory attributes to noodles. Majority of instant noodles in the market are deep-fried in the production line. Adding FibroTec to instant noodle formula reduces fat absorptions during deep-frying, therefore increases the shelf-life of the product while enhancing its crispiness and texture. Plenty of noodles and pasta in the market are too sticky when they are cooked incorrectly. FibroTec prevents stickiness of pasta and noodles if overcooked.

- Applying FibroTec in Pasta and Noodles

- Depending on the characteristics of the product, FibroTec MCC generally is applied on pasta and noodle with combinations of other hydrocolloids such as CMC, or guar gum.

- It is recommended to disperse FibroTec based stabilizing system in 50 to 70C of milk or water at a speed of 2000-15000RPM, before adding other ingredients. Salt and acidic materials should be added last.

- Key Functionalities

- Reduces Oil Absorption

- Strengthens Tensile

- Emulsifies Oil and Fat

- Adds Body

- Reduces Sogginess

- Retains Moisture

- Improves Mouth-feel

- Improves Texture

- Carries and Enhances Color

- Applications

- Pasta

- Instant Noodle

- Dumplings

- Rice Noodles, etc.

- Applying FibroTec in Pasta and Noodles

Regulatory & Compliance

- Certifications & Compliance