Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Product Highlights

Aquanyl 612 is employed where additional resilience is a specific requirement for the application, for instance in the ball valve industry where the application of valve seat seals benefits greatly from this material. In addition due to its copolymer make up with nylon 12 the product has a Lower moisture uptake than cast nylon providing the obviousbenefit of improved dimensional stability.

- Benefits

- Greater degree of material resilience

- Plasticised benefits without the associated problems

- Reduced water absorption

- Improved dimensional stability

- Good mechanical, thermal and chemical resistance

- properties

- Improved impact resistance

- Good PV and Load bearing capabilities

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Industry Users

- Petrochemical

- Steel mills

- Construction

- Quarrying/mining

- Transport

- Cranes

- Food and drink packaging

- Conveyors

- Bottling and canning

- Offshore

- Pharmaceuticals

- Applications

- Seal rings

- Sheaves/Pulleys

- Pipe clamps

- Winches

- Thrust rollers

- Difts

- Nozzles

- Bespoke Components

- Bushes

Properties

- Mechanical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Modulus | 2000-2200 | psi | ISO 604:2002 |

| Compressive Strength | 95-120 | psi | ISO 604:2002 |

| Density | 1.14 | g/cm³ | ISO 1183:1997 |

| Dynamic Coefficient of Friction | 0.188 | - | - |

| Elongation at Break | min. 40 | % | ISO 527-1/2:1993 |

| E-modulus | 3400-3700 | psi | ISO 527-1/2:1993 |

| Flexural Modulus | 2700-3000 | psi | ISO 178:2001 |

| Flexural Strength | 90-100 | psi | ISO 178:2001 |

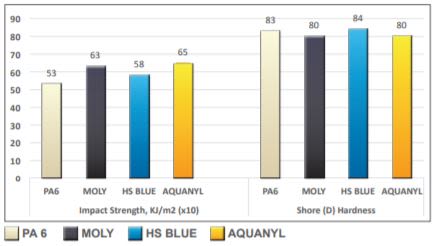

| Hardness (Shore D ) | 80 | Shore D | ISO 868: 2003 |

| Izod Impact Strength | 6.0-7.0 | ft.lb/inE2 | ISO 180:2000 |

| K-Factor (wear factor) | 2.9X10E-5 | - | - |

| Limiting PV | 100 | psi.ft/min | - |

| Tensile Strength at Yield | 74-78 | psi | - |

| Water Absorption (24 hrs Saturation) | 5 | % | - |

| Water Absorption (24 hrs) | 0.15 | % | - |

| Value | Units | Test Method / Conditions | |

| Coefficient of Linear Thermal Expansion | 8x10E-5 | °F,E-1 | - |

| Flammability | HB | - | - |

| Glass Transition Temperature | 63 | °F | - |

| Heat Deflection Temperature, HDT/A | 75 | °F | - |

| Maximum/Minimum Continuous Service Temperatures | 100/-40 | °F | - |

| Maximum/Minimum Intermittent Service Temperatures | 160/-100 | °F | - |

| Melting Temperature | 216 | °F | - |

| Thermal Conductivity | 0.26 | °F | - |

| Value | Units | Test Method / Conditions | |

| Comparative Tracking Index | 600 | CTI | IEC 60093:1980-01 |

| Dielectric Constant | 3.7 - 4 | - | IEC 60250:1969-01 |

| Dielectric Strength | 25 | kV/in | IEC 60243:-1:1998-01 |

| Dissipation Factor | 0.04 | - | IEC 60250:1969-01 |

| Moisture Absorption (Equilibrium) | 1.8 | % | ISO 62:1999 (modified) |

| Surface Resistivity | min. 1x10E12 | ohm.m | IEC 60093:1980-01 |

| Volume Resistivity | min. 1x10E13 | ohm.m | IEC 60243:-1:1998-01 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Aquanyl PA 6/12

Packaging & Availability

- Availability

Nylacast Aquanyl 612 is available as standard plate, rod and thousands of tube OD/ID configurations in several different Lengths.