Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Benefits

- Significantly improved impact resistance

- Improved insensitivity against stresses, sharp edges, notches and scratches

- Free of internal stresses

- Good mechanical, thermal and chemical resistance properties

- Improved noise reduction capability

- Good PV and load bearing capabilities

- Good dimensional stability

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Industry Users

- Aerospace

- Pharmaceuticals

- Railways

- Steel Mills

- Ship Building

- Quarrying/mining

- Food and drink packaging

- Cranes

- Bottling and canning

- Conveyors

- Applications

- Rollers

- Wheels

- Wear pads

- Sheaves

- Switch collar

- Wear strips

- Washers

- Clamps

- Bearings

- Bespoke Impact Ring

- Load support

Properties

- Color

- Mechanical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Modulus | 2300-2700 | psi | ISO 604:2002 |

| Compressive Strength | 115-125 | psi | ISO 604:2002 |

| Density | 1.11 | g/cm³ | ISO 1183:1997 |

| Dynamic Coefficient of Friction | 0.195 | - | — |

| Elongation at Break | max. 10 | % | ISO 527-1/2:1993 |

| E-modulus | 3100-3400 | psi | ISO 527-1/2:1993 |

| Flexural Modulus | 2300-2600 | psi | ISO 178:2001 |

| Flexural Strength | 92-95 | psi | ISO 178:2001 |

| Hardness (Shore D ) | X | Shore D | ISO 868: 2003 |

| Izod Impact Strength | 13.9 | ft.lb/inE2 | ISO 180:2000 |

| K-Factor (wear factor) | 3.5x10E-5 | - | — |

| Limiting PV | 100 | psi.ft/min | — |

| Tensile Strength at Yield | 60/70 | psi | — |

| Water Absorption (24 hrs Saturation) | 5.3 | % | — |

| Water Absorption (24 hrs) | 0.18 | % | — |

| Value | Units | Test Method / Conditions | |

| Coefficient of Linear Thermal Expansion | 8x10E-5 | °F,E-1 | — |

| Flammability | HB | - | — |

| Glass Transition Temperature | 60 | °F | — |

| Heat Deflection Temperature, HDT/A | 72 | °F | — |

| Maximum/Minimum Continuous Service Temperatures | 100/-40 | °F | — |

| Maximum/Minimum Intermittent Service Temperatures | 150/-100 | °F | — |

| Melting Temperature | 219.5 | °F | — |

| Thermal Conductivity | 0.26 | °F | — |

| Value | Units | Test Method / Conditions | |

| Comparative Tracking Index | 600 | CTI | IEC 60093:1980-01 |

| Dielectric Constant | 3.7 - 4 | - | IEC 60250:1969-01 |

| Dielectric Strength | 25 | kV/in | IEC 60243:-1:1998-01 |

| Dissipation Factor | 0.09 | - | IEC 60250:1969-01 |

| Moisture Absorption (Equilibrium) | 1.7 | % | ISO 62:1999 (modified) |

| Surface Resistivity | 1x10E12 | ohm.m | IEC 60093:1980-01 |

| Volume Resistivity | 1x10E13 | ohm.m | IEC 60243:-1:1998-01 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

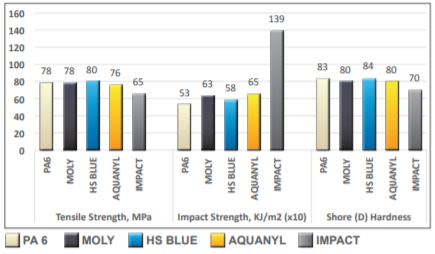

- Impact

Packaging & Availability

- Availability

Nylacast Impact is available as standard plate, rod and thousands of tubes OD/ID configurations in several different lengths.