Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Benefits

- "First authentic lubricated nylon

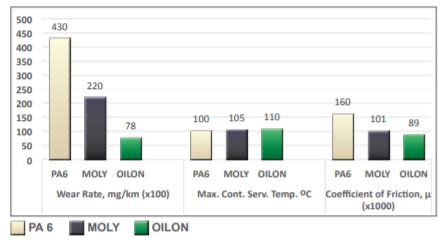

- Improved wear and abrasion resistance

- Improved PV characteristics

- Improved coefficient of friction and stick/slip characteristics

- Consistent wear performance throughout product life

- Reduced water absorption

- Excellent mechanical, thermal and chemical resistance properties

- Good dimensional stability

- FDA compliant for direct food contact applications

- Blended liquid lubricant system"

- Product Highlights

A uniformed distribution of the lubricant throughout the product guarantees a constant performance over the whole service life and improvements in rate of wear, sliding frictional properties, abrasion resistance and stick slip performanceare just a few of the benefits offered by this material. Oilonhas been successful in considerably enlarging the application possibilities of nylons in many areas and specificallythat of unlubricated moving parts. Oilon has acquired an unmatchable track record over the past 40 years andcontinues to go from strength to strength, for Nylacast hasover this period produced thousands of tons of Oilon and thetrend continues.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Industry Users

- Petrochemical

- Steel mills

- Construction

- Quarrying/mining

- Transport

- Cranes

- Food and drink packaging

- Conveyors

- Bottling and canning

- Offshore

- Pharmaceuticals

- Applications

- Wear pads

- Support rails

- Sheaves

- Rollers

- Guide plates

- Bearings

- Spacers

- Pulleys

- Spacers

- Brake blocks

- Conveyor rail

- Pipe Clamps

- Gears Bushes

- Wear Strips

- espoke Components

Properties

- Color

- Mechanical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

| Compressive Modulus | 2100-2500 | MPa | ISO 604:2002 |

| Hardness | 82 | Shore D | ISO 868: 2003 |

| Compressive Strength | 110-120 | MPa | ISO 604:2002 |

| Density | 1.138 | g/cm3 | ISO 1183:1997 |

| Dynamic Coefficient of Friction | 0.089 | - | - |

| Elongation at Break | max. 30 | % | ISO 527-1/2:1993 |

| E-modulus | 3500-3700 | MPA | ISO 527-1/2:1993 |

| Flexural Modulus | 3300-3600 | MPa | ISO 178:2001 |

| Flexural Strength | 105-125 | MPa | ISO 178:2001 |

| Izod Impact Strength | 5.0-6.5 | kJ/mm2 | ISO 180:2000 |

| K-Factor (wear factor) | 2.2x10E-5 | mm3/Nm | - |

| Limiting PV | 100 | MPa/m | - |

| Tensile Strength at Yield | 74-78 | MPa | ISO 527-1/2:1993 |

| Water Absorption (24 hrs Saturation) | 6.1 | % | ISO 62:1999 |

| Water Absorption (24 hrs) | 0.2 | % | ISO 62:1999 (modified) |

| Value | Units | Test Method / Conditions | |

| Coefficient of Linear Thermal Expansion | 8x10E-5 | °C-1 | ISO 11359-2:1999 |

| Flammability | HB | - | IEC 60695-11-10:2003-8 |

| Glass Transition Temperature | 65 | °C | ISO 11359:1999 |

| Heat Deflection Temperature, HDT/A | 75 | °C | ISO 75 |

| Maximum/Minimum Continuous Service Temperatures | 110/-40 | °C | - |

| Maximum/Minimum Intermittent Service Temperatures | 170/-100 | °C | - |

| Melting Temperature | 222 | °C | - |

| Thermal Conductivity | 0.25 | W/moC | ISO 8301:1991 |

| Value | Units | Test Method / Conditions | |

| Comparative Tracking Index | 600 | CTI | IEC 60093:1980-01 |

| Dielectric Constant | 3.7 - 4 | - | IEC 60250:1969-01 |

| Dielectric Strength | 25 | kV/m | IEC 60243:-1:1998-01 |

| Dissipation Factor | 0.014 | - | IEC 60250:1969-01 |

| Moisture Absorption (Equilibrium) | 2 | % | ISO 62:1999 (modified) |

| Surface Resistivity | 1x10E12 | ohm.m | IEC 60093:1980-01 |

| Volume Resistivity | 1x10E13 | ohm.m | IEC 60243:-1:1998-01 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Oilon

Packaging & Availability

- Availability

Nylacast Oilon is available as standard plate, rod and over thousands of tubes OD/ID configurations in several different lengths.