Knowde Enhanced TDS

Identification & Functionality

- Chemical Family

- Polymer Name

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

- Benefits

- Good mechanical, thermal and chemical resistance properties

- Universally acknowledged as the primary engineering

- polymer

- Good PV and load bearing capabilities

- Improved characteristics over extruded polyamides

- Good wear and abrasion resistance

- Good dimensional stability, largely free from internal stresses

- FDA Compliance

- Available in a wide range of sizes and colors

- Product Highlights

Specifically as the material has a higher tensile,compressive and impact strength as well as an improve dresistance to creep and heat aging. The reasons forthese improved characteristics are high crystalinity anda remarkably higher molecular weight. Due to low water absorption, mechanical properties and dimensions are morestable, making it suited for components that have to meetcloser tolerances. Abrasion resistance and overall wear performance are probably the material’s most important characteristics. For use in bearing applications and in applications where food contact is involved, cast nylons maybe offered as a material conforming to FDA approvals.

Natural cast nylon has the ability to operate effectively without the need for lubricants and has an increased resistance to wear of over 5 times that for plain bearings manufactured from non-ferrous metals. As is the case with virtually all nylons it is easy to machine, pleasant to work with and relatively light weight – one eighth that of brass - making the handling and fitting of large components manufactured in cast nylon a relatively easy matter.

Applications & Uses

- Applications

- Plastics & Elastomers End Uses

- Industry Users

- Petrochemical

- Aerospace

- Railways

- Ship building

- Food and drink packaging

- Bottling and canning

- Pharmaceuticals

- Steel mills

- Quarrying/mining

- Cranes

- Shoe manufacturing

- Conveyors

- Applications

- Rollers

- Switch collar

- Washers

- Bearings

- Load support

- Bushes

- Centralizers

- Cable drums

- Guide clutch

- Seals

- Blockers

- Wear pads

- Chain Guide

- Clamps

- Bespoke Components

Properties

- Mechanical Properties

- Thermal Properties

- Electrical Properties

| Value | Units | Test Method / Conditions | |

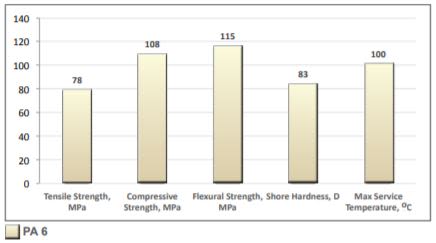

| Compressive Modulus | 2100-2700 | MPa | ISO 604:2002 |

| Compressive Strength | 95-120 | MPa | ISO 604:2002 |

| Density | 1.141 | g/cm3 | ISO 1183:1997 |

| Dynamic Coefficient of Friction | 0.16 | - | - |

| Elongation at Break | min. 20 | % | ISO 527-1/2:1993 |

| E-modulus | 3400-3600 | MPA | ISO 527-1/2:1993 |

| Flexural Modulus | 3300-3600 | MPa | ISO 178:2001 |

| Flexural Strength | 105-125 | MPa | ISO 178:2001 |

| Hardness (Shore D ) | 83 | Shore D | ISO 868: 2003 |

| Izod Impact Strength | 4.5-6.0 | kJ/mm2 | ISO 180:2000 |

| K-Factor (wear factor) | 4.3x10E-5 | mm3/Nm | - |

| Limiting PV | 100 | MPa/m | - |

| Tensile Strength at Yield | 75-80 | MPa | ISO 527-1/2:1993 |

| Water Absorption (24 hrs Saturation) | 7 | % | ISO 62:1999 |

| Water Absorption (24 hrs) | 0.3 | % | ISO 62:1999 (modified) |

| Value | Units | Test Method / Conditions | |

| Coefficient of Linear Thermal Expansion | 8x10E-5 | °C-1 | ISO 11359-2:1999 |

| Flammability | HB | - | IEC 60695-11-10:2003- |

| Glass Transition Temperature | 65 | °C | ISO 11359:1999 |

| Heat Deflection Temperature, HDT/A | 75 | °C | ISO 75 |

| Maximum/Minimum Continuous Service Temperatures | 100/-40 | °C | - |

| Maximum/Minimum Intermittent Service Temperatures | 170/-100 | °C | - |

| Melting Temperature | 223 | °C | - |

| Thermal Conductivity | 0.26 | W/moC | ISO 8301:1991 |

| Value | Units | Test Method / Conditions | |

| Comparative Tracking Index | 600 | CTI | IEC 60093:1980-01 |

| Dielectric Constant | 3.7 - 4 | - | IEC 60250:1969-01 |

| Dielectric Strength | 25 | kV/m | IEC 60243:-1:1998-01 |

| Dissipation Factor | 0.02 | - | IEC 60250:1969-01 |

| Moisture Absorption (Equilibrium) | 2.5 | % | ISO 62:1999 (modified) |

| Surface Resistivity | min. 1x10E12 | ohm.m | IEC 60093:1980-01 |

| Volume Resistivity | min. 1x10E13 | ohm.m | IEC 60243:-1:1998-01 |

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- PA 6 Natural

Packaging & Availability

- Availability

Nylacast PA 6 Natural is available in standard plate, rod and over thousands of tube OD/ID configurations in several different lengths.