Knowde Enhanced TDS

Identification & Functionality

- Additives Included

- Chemical Family

- Polymer Name

- Composite Materials Functions

- Plastics & Elastomers Functions

- Technologies

Features & Benefits

- Materials Features

- Features

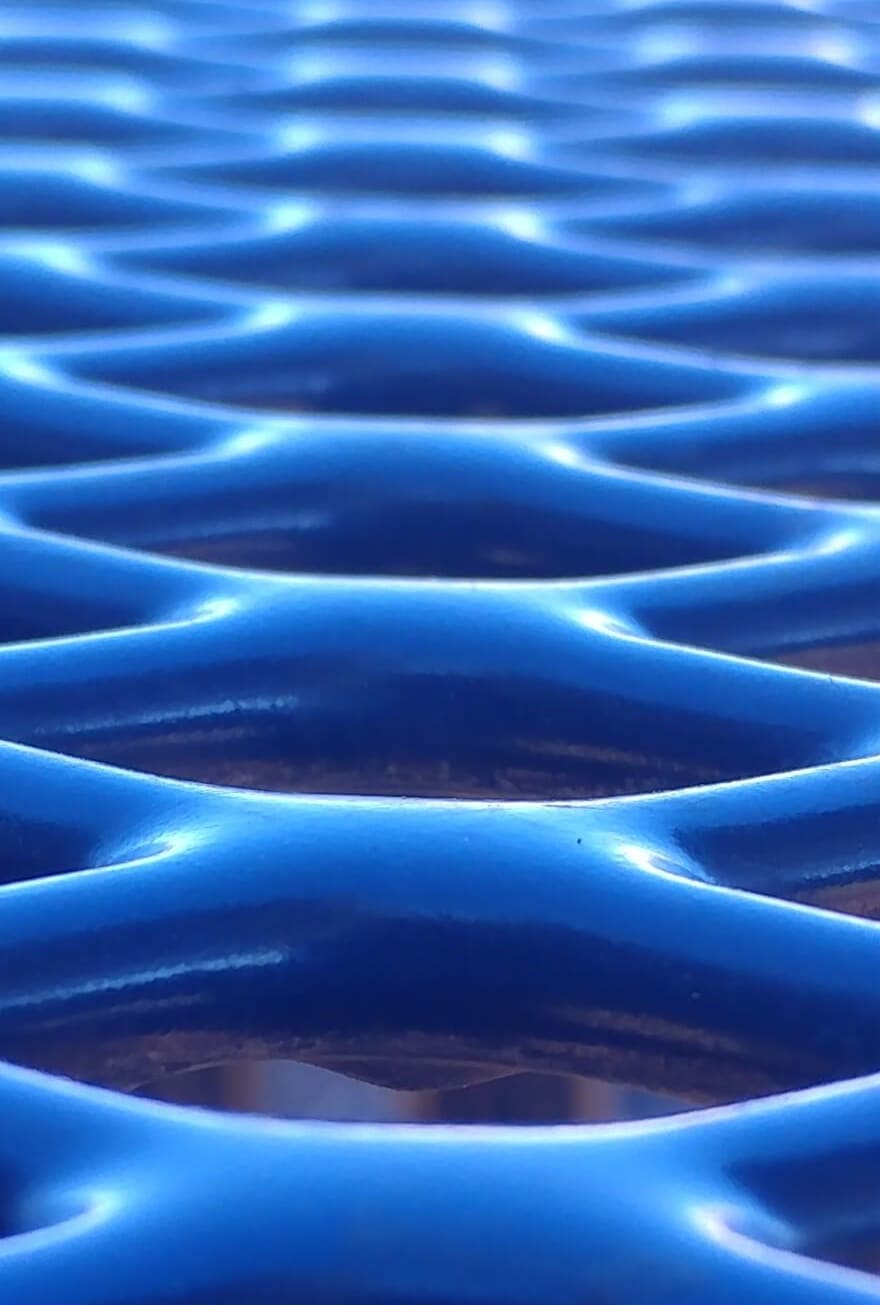

- NYCOTUFF 2176 was specifically formulated to offer high flexibility and strength, superior toughness and high impact resistance, even at low temperatures. The alloy offers improved recyclability with minimum loss in physical properties after repeated extrusions.

- This material performs well in applications where softness, ductility and exceptional impact resistance are required.

Applications & Uses

- Markets

- Plastics & Elastomers Processing Methods

- Applications

- NYCOTUFF 2176 is available with custom additive packages: heat stabilizer, UV stabilizer and/or flame retardant.

- Typical extrusion applications include hose mandrels for rubber vulcanization, high-pressure & hydraulic hoses, and flexible & vacuum tubing.

Properties

- Mechanical Properties

- Physical Properties

- Thermal Properties

| Value | Units | Test Method / Conditions | |

| Durometer | 64 | Shore D | ASTM D 2240 |

| Flexural Modulus | 92 | psi | ASTM D 790 |

| Flexural Strength | 4000 | psi | ASTMD 790 |

| Notched Izod Impact | 16 (NB) | ft.lbs./in | ASTM D 256 |

| Tensile Strength | 6400 | psi | ASTM D 638 |

| Ultimate Elongation | 300+ | % | ASTM D 638 |

| Value | Units | Test Method / Conditions | |

| Linear Mold Shrinkage (Normal) | 1 | % | ASTM D 955 |

| Linear Mold Shrinkage (Parallel) | 0.8 | % | ASTM D 955 |

| Specific Gravity | 1.07 | - | ASTM D 792 |

| Water Absorption (at 24 hours) | 1 | % | ASTM D 570 |

| Value | Units | Test Method / Conditions | |

| Melting Temperature | 423 | °F | ASTM D 789 |

Regulatory & Compliance

- Certifications & Compliance